Efficient rotating stamping shaping mold

A stereotyped mold and high-efficiency technology, applied in the field of stamping molds, can solve the problems of low production efficiency and achieve the effects of fast processing speed, novel structure and high usable value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

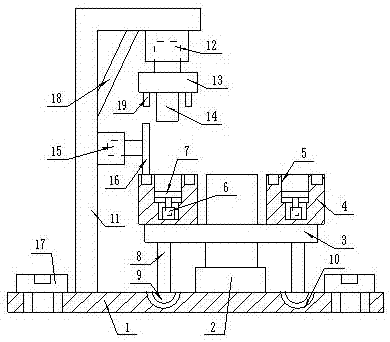

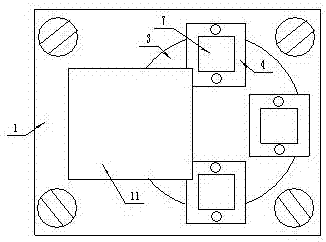

[0014] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a high-efficiency rotary stamping and shaping die includes a rectangular base 1, the right end of the upper surface of the rectangular base 1 is fixedly connected with a driving motor 2 with a rotating end upward, and the rotating end of the driving motor 2 is fixedly connected with a fixed disc 3 , the upper surface of the fixed disk 3 is fixedly connected with a plurality of lower molds 4, each of the upper surfaces of the lower molds 4 is processed with a stamping concave film 5, and each of the inner and lower surfaces of the stamping concave film 5 is processed with a rectangular shape. Groove, the inner and lower surface of each said rectangular groove is fixedly connected with an electric control telescopic push rod 6 with the telescopic end upward, and the telescopic end of each said electric control telescopic push rod 6 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com