Efficient cement board manufacturing mould for building construction

A technology for building construction and manufacturing molds, applied in the direction of manufacturing tools, molds, mold auxiliary parts, etc., can solve the problems of simple mold structure, slow drying speed, low production efficiency, etc., achieve good energy saving effect, easy demoulding, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

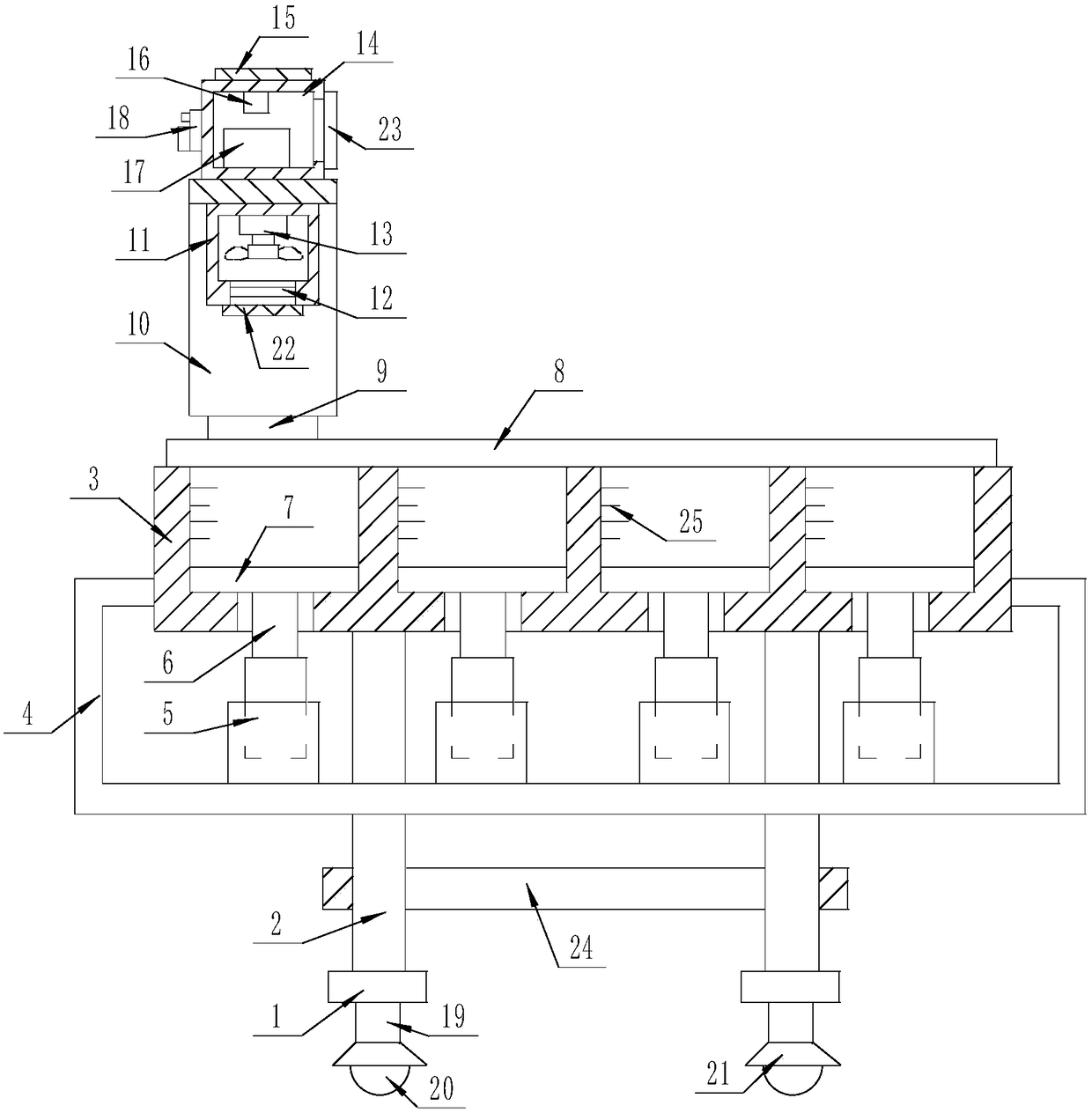

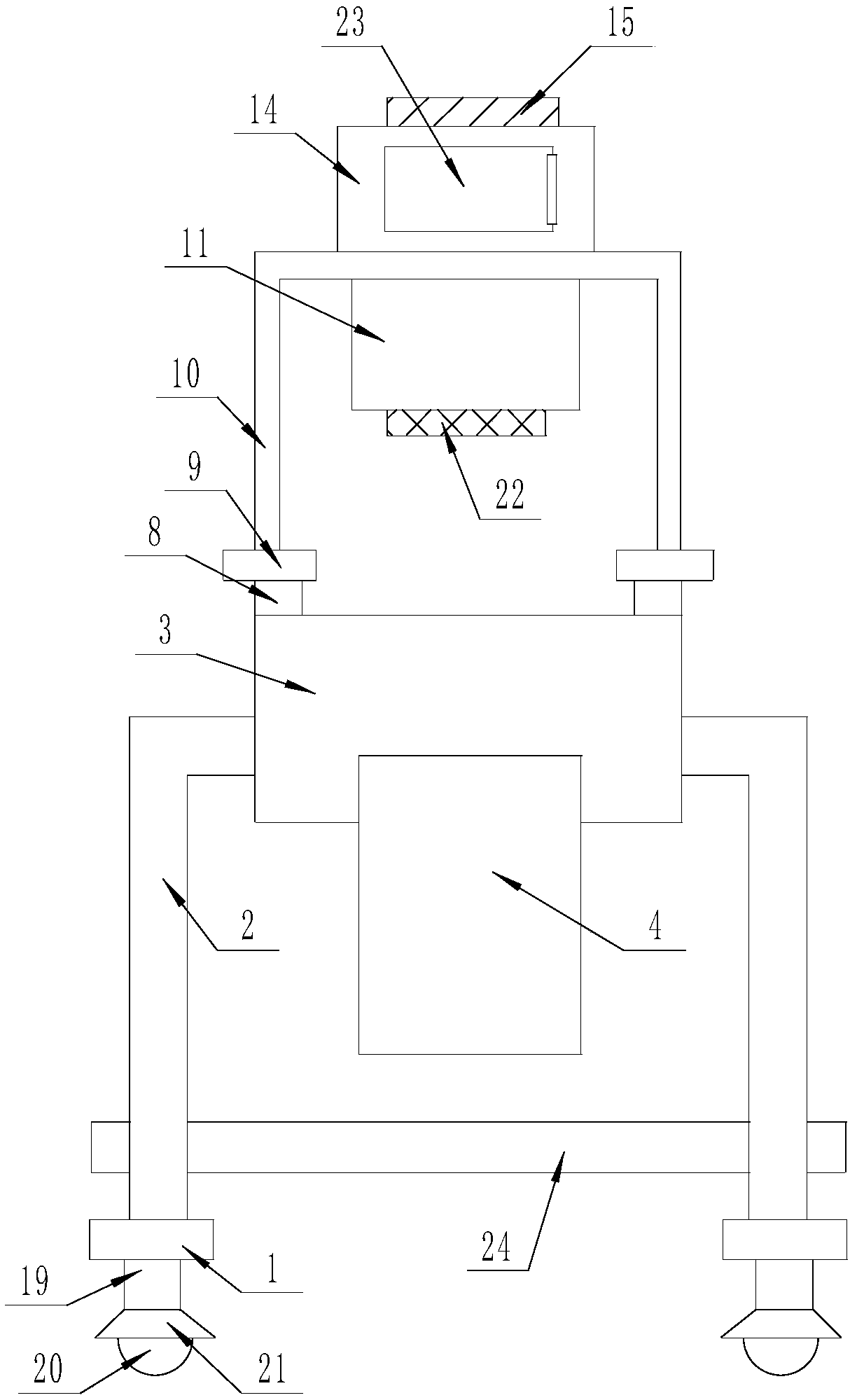

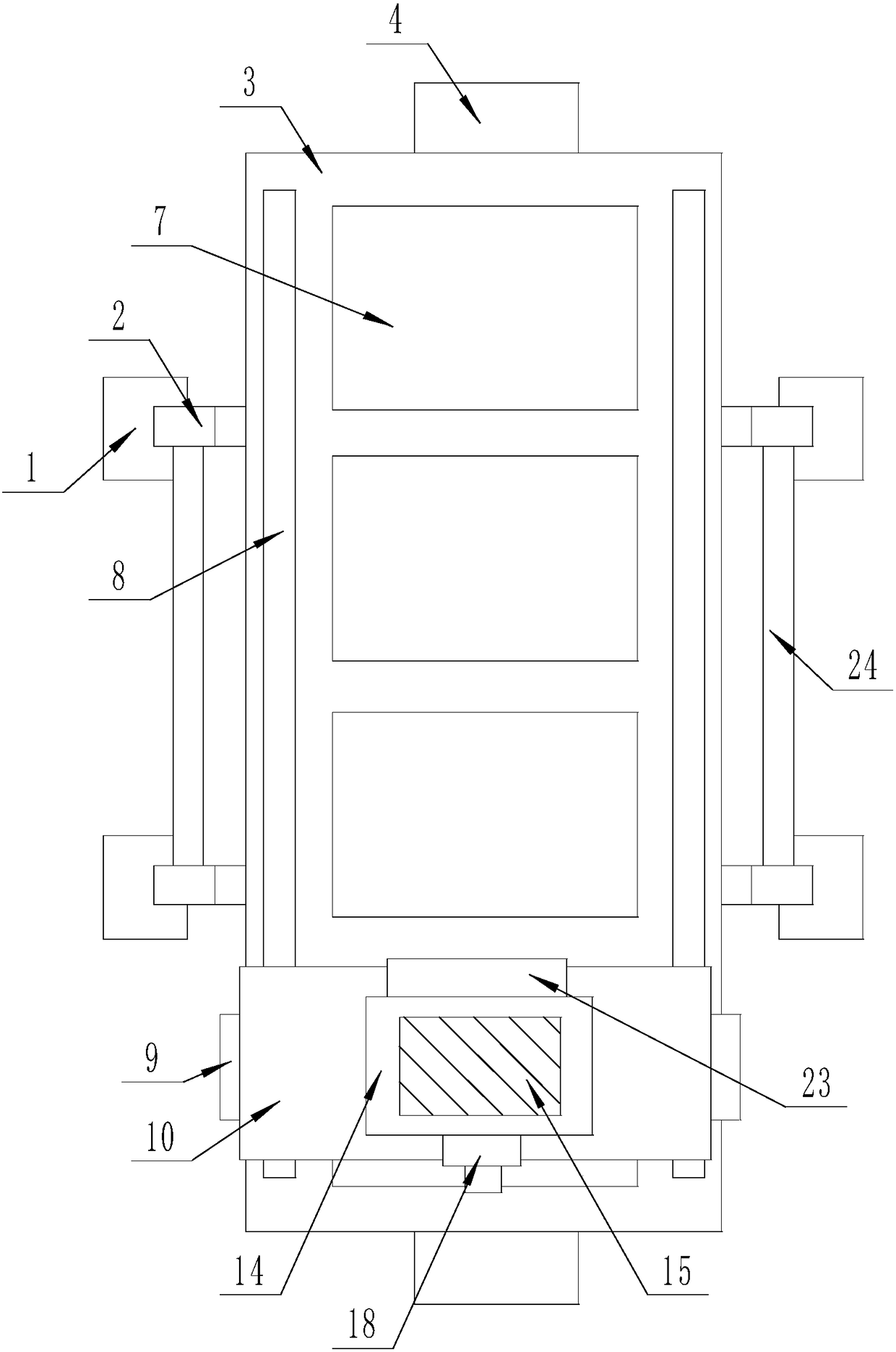

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 As shown, a high-efficiency cement board manufacturing mold for building construction includes two pairs of rectangular bases 1, each of which is fixedly connected with an L-shaped strut 2 on the upper surface of the rectangular base 1, and the side surface of each of the L-shaped struts 2 A mold base 3 is fixedly connected, and the upper surface of the mold base 3 is processed with a plurality of cement board cavities, and the lower surface of each cement board cavity is processed with a circular positioning through hole, and the side surface of the mold base 3 is fixed. A folded support plate 4 is connected, and the upper surface of the folded support plate 4 is fixedly connected with a plurality of electric control telescopic push rods 5 with telescopic ends upward, and each telescopic end of the electric control telescopic push rod 5 is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com