Maskless exposure system and exposure method thereof

An exposure system, maskless technology, applied in the field of semiconductor manufacturing, to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solution and advantages of the present invention more clear, the following will be further described in detail in conjunction with the accompanying drawings.

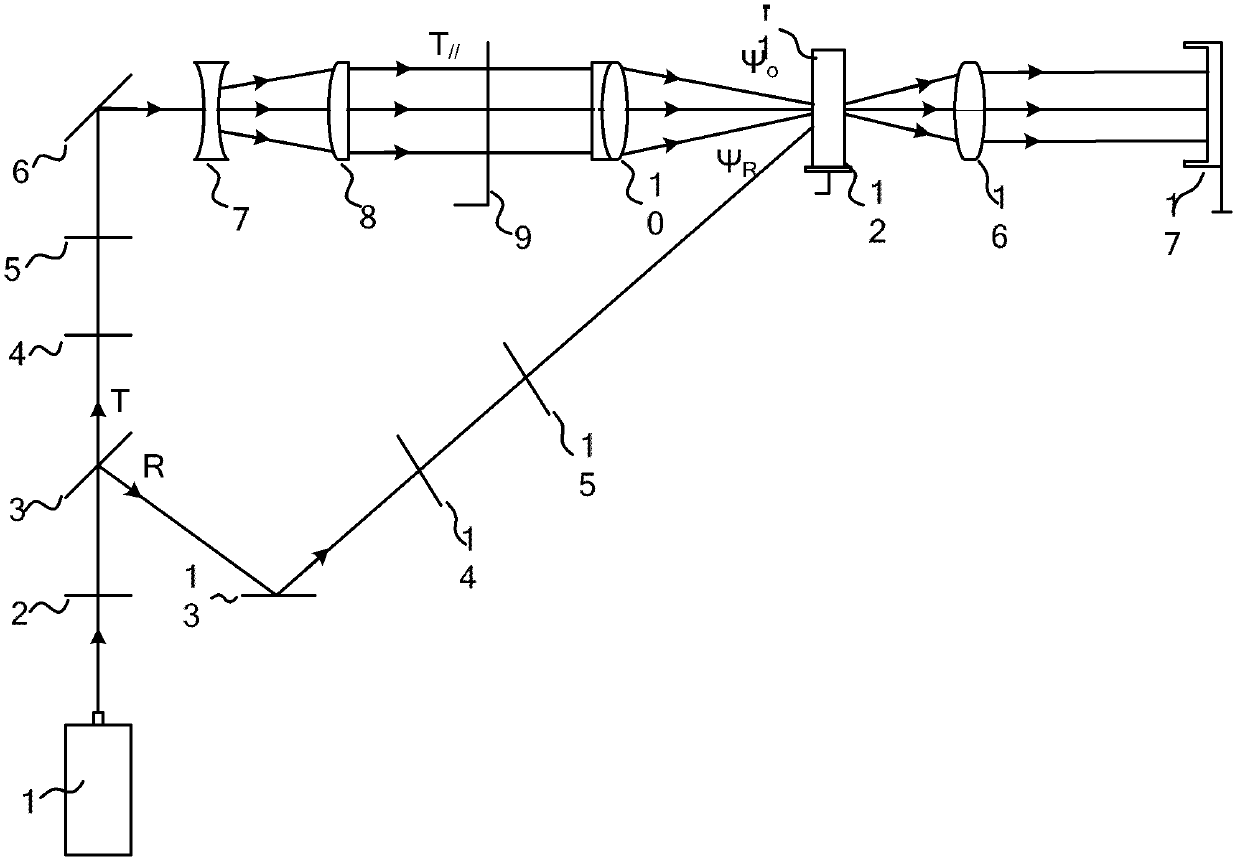

[0038] figure 1 It is a schematic diagram of the overall structure of a maskless exposure system in an embodiment of the present invention. The maskless exposure system includes: a laser light source 1, a half-wave plate 2, a beam splitter 3, a first light intensity attenuator 4, a first electric shutter 5, a first reflector 6, a beam expander 7, a quasi- Straight mirror 8, mask plate support frame 9, Fourier transform lens 10, photorefractive crystal 11, fixed turntable 12, second mirror 13, second light intensity attenuator 14, second electric shutter 15, imaging lens 16 and Wafer support frame 17.

[0039] The light emitted by the laser light source 1 reaches the beam splitter 3 after passing through the half-wave plate 2, and is divided into a transmitted beam T and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com