Dry-sand preconsolidation vibrating foundation reinforcing method

A technology for foundation reinforcement and dry sand, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problems of large impact, affecting the compactness of backfill sand, and high strength of the foundation surface, so as to ensure physical and mechanical properties, improve the availability The effect of utilizing value and enhancing the overall carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention will be described in further detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

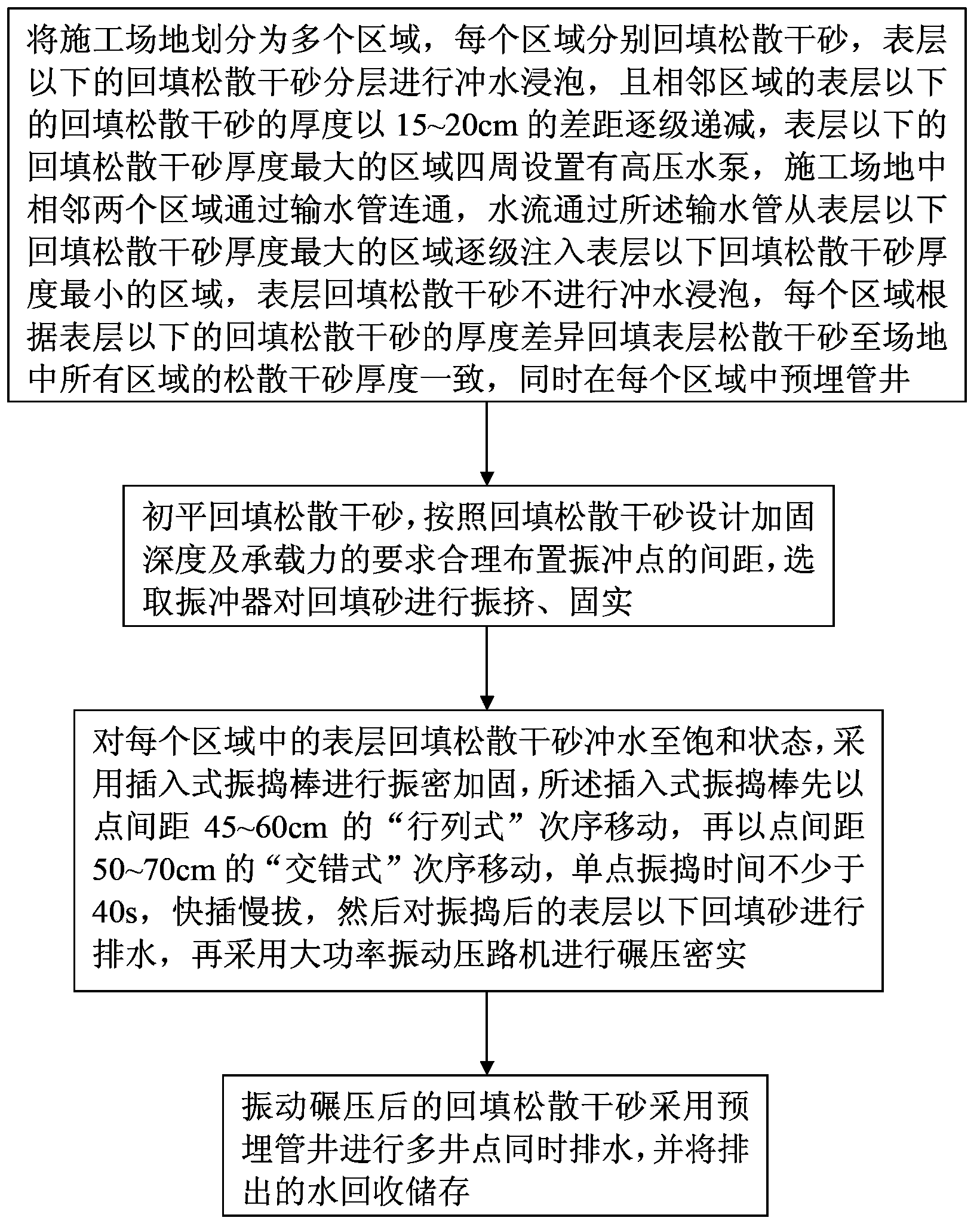

[0020] The invention provides a kind of dry sand pre-densified vibration foundation reinforcement method, comprising:

[0021] Step 1. Divide the construction site into several areas according to the scope of the construction site, surrounding transportation road conditions and construction period requirements, and control the area of each area at 20,000 to 30,000 m 2 Clay masonry is used to separate the cofferdams between the areas, so as to facilitate the flushing operation in different areas, clean up the weak layer of the base debris, etc. After compaction and leveling, use dump trucks to transport loose dry sand to backfill each area separately , the coarse sand in the gravel is backfilled in the center of the area at 10,000 to 20,000 m 2 , the middle sand is backfilled in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com