Novel ultrasonic wave belt cutting machine

A technology of ultrasonic and tape cutting machine, which is applied in metal processing, coiling strips, thin material processing, etc. It can solve the problems of occupying space, work efficiency and tape cutting style that cannot keep up with the progress and development of the times, and noise generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

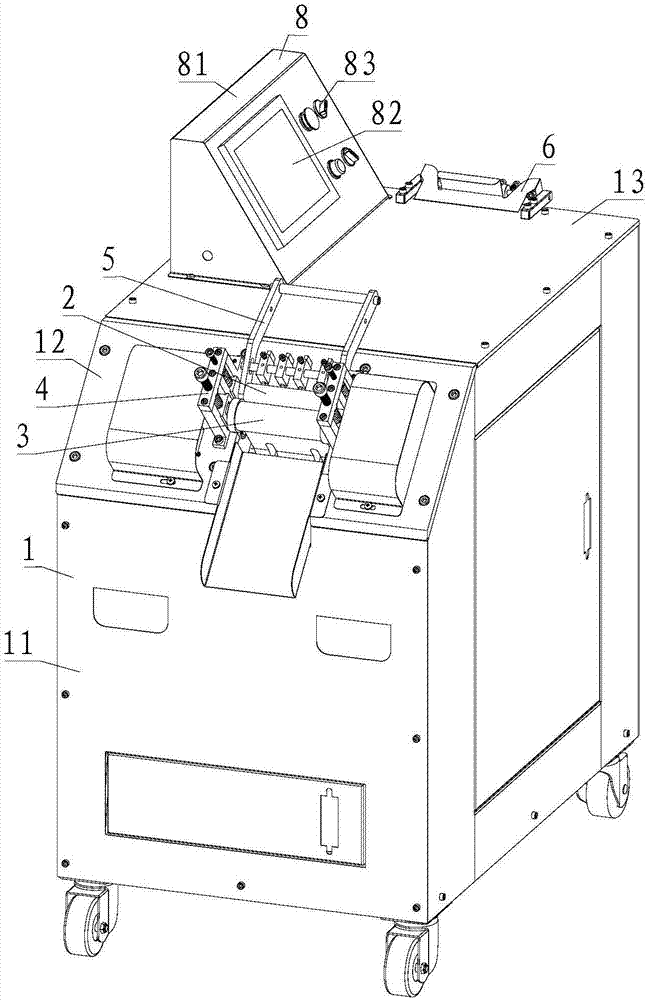

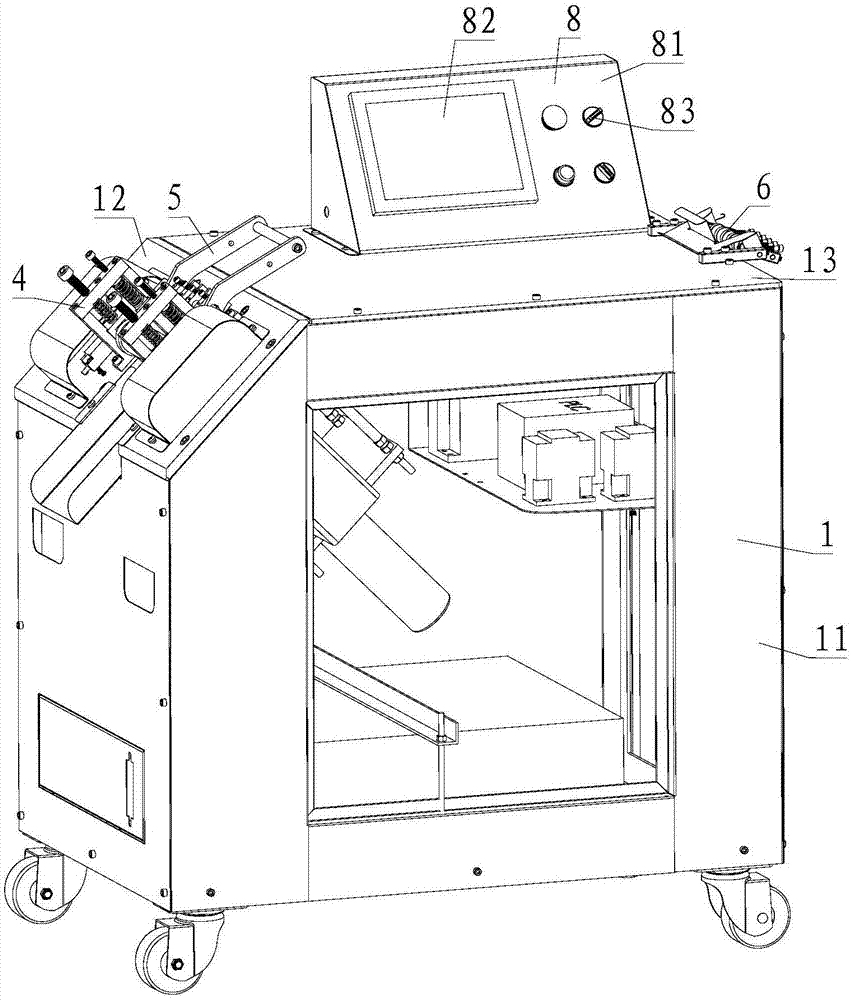

[0062] Please refer to Figure 1 to Figure 5 , Embodiment 1 of the present invention is:

[0063] A new type of ultrasonic cutting machine, including a frame 1, also includes a feeding mechanism 2 and a roll cutting mechanism 3, the frame 1 includes a main housing 11 and a first workbench 12, the first workbench 12 is fixed on The top of the main housing 11; the feeding mechanism 2 includes a feeding motor 21, a feeding roller 22 and a feeding roller 23, the feeding motor 21 drives the feeding roller 22 to rotate, and the feeding roller 23 is located on the feeding roller 23. Directly above the roller 22, the feeding roller 22 and the feeding pressure roller 23 are connected in rotation with the first workbench 12, and the feed motor 21 is fixed on the first workbench 12; Mechanism 3 comprises hobbing motor 31, hobbing cutter 32 and ultrasonic horn 33, and described hobbing motor 31 drives described hobbing cutter 32 to rotate, and described hobbing cutter 32 is cylindrical, ...

Embodiment 2

[0064] Please refer to Figure 1 to Figure 5 , the second embodiment of the present invention is:

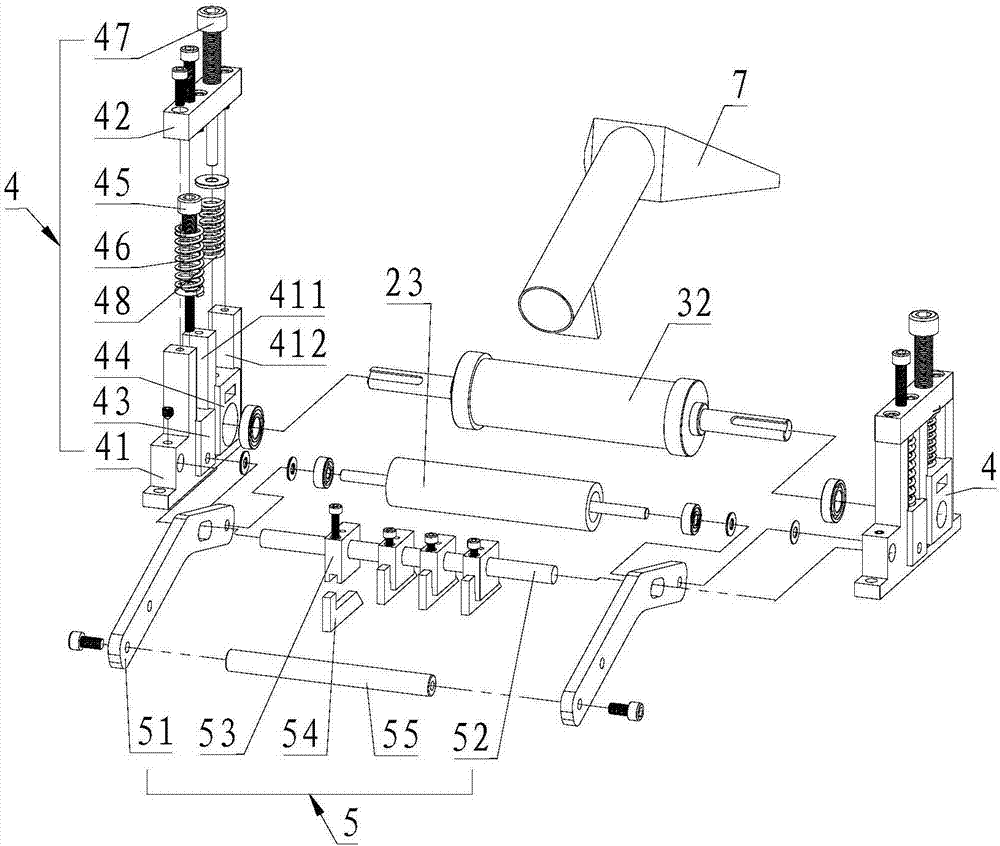

[0065]A new type of ultrasonic belt cutting machine, on the basis of the first embodiment, also includes a pre-tension mechanism 4, the pre-tension mechanism 4 includes a fixed seat 41, a pressure plate 42, a first slider 43, a second slider 44, a first A screw guide post 45, a first spring 46, a second screw guide post 47 and a second spring 48, the pressing plate 42 is fixed on the top surface of the fixed seat 41, and the upper surface of the fixed seat 41 is provided with a first recess groove 411 and a second groove 412, the first slider 43 is slid up and down in the first groove 411, and the second slider 44 is slid up and down in the second groove 412, so The upper end of the first screw guide post 45 is screwed to the pressure plate 42, and the lower end is slidably connected to the first slider 43. The first spring 46 is sleeved on the first screw guide post 45, and is...

Embodiment 3

[0066] Please refer to Figure 1 to Figure 5 , Embodiment three of the present invention is:

[0067] A new type of ultrasonic tape cutting machine, on the basis of the first or second embodiment, the feeding mechanism 2 also includes a first bevel gear set 24 and a first bearing seat 25, and the feeding motor 21 passes through the first bevel gear Group 24 is connected with described feeding roller 22, and the two ends of described feeding roller 22 are respectively connected with described first workbench 12 through a described first bearing seat 25; 34. The ultrasonic transducer 35, the first fan and the second fan, the ultrasonic generator 34, the ultrasonic transducer 35, and the ultrasonic welding head 33 are connected sequentially from bottom to top, and the air outlet of the first fan faces the The ultrasonic welding head 33, the air outlet of the second fan faces the ultrasonic transducer 35.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com