Forming device for seamless outer protective tube for high-density polyethylene prefabricated directly-buried elbow and forming technology thereof

A high-density polyethylene, prefabricated direct-buried technology, applied in the field of outer protection pipe bending processing, can solve the problems of short service life and low structural strength, and achieve the effect of long service life and high overall structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

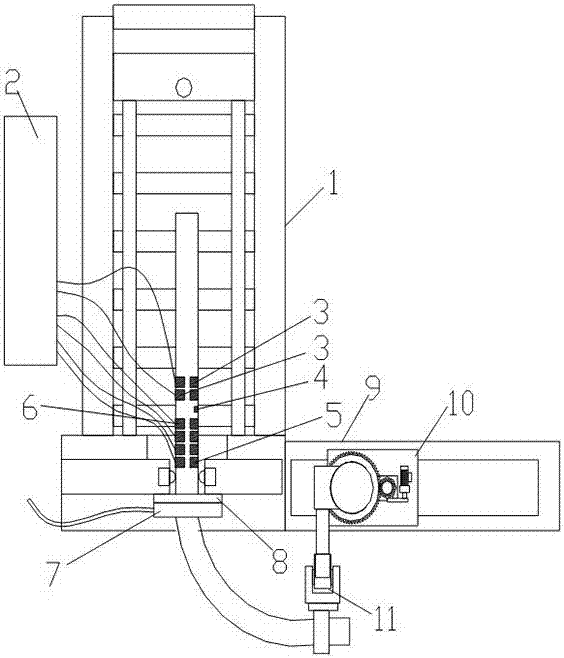

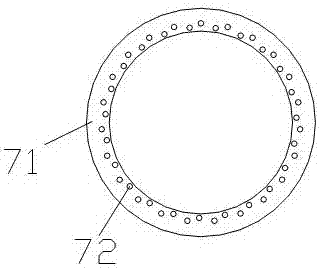

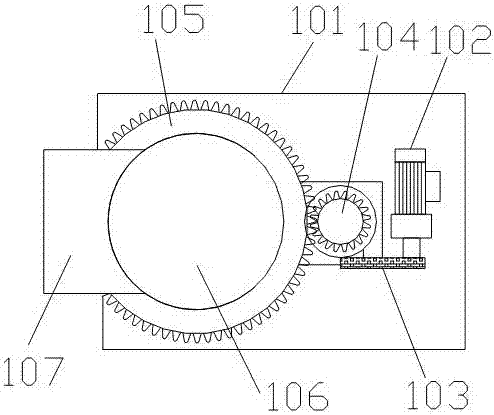

[0021] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a high-density polyethylene prefabricated direct-buried elbow seamless outer protective tube forming device consists of an elbow pushing machine 1, a controller 2, several heating plates, a cooling air pipe 7, a polytetrafluoro plate tube 8, Track 9, electric stretch bending machine 10 and pipe bending fixture 11, heating sheet includes preheating heating sheet 3, pipe top heating sheet 4, inner arc heating sheet 5 and outer arc heating sheet 6, polytetrafluoro plate tube 8 is arranged on At the outlet end of the bent pipe pushing machine 1, the cooling air pipe 7 is installed on the outside of the PTFE plate tube 8, and the inner side of the annular body 71 of the cooling air pipe 7 is provided with a number of air holes 72, and the track 9 is arranged on the outlet side of the bent pipe pushing machine 1. Electric stretch bending machine 10 is made up of rail car 101, reduction motor 102, pinion disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com