Drill pipe clamping and straightening device with two-way position compensation function and drilling straightening method

A technology of axial position and axial compensation, which is applied in the direction of drill pipe, drill pipe, earthwork drilling, etc., and can solve the problem of large structural size and weight of the clamp, clamping clamping force, slip force surface Weakness and other problems, to achieve the effect of improving service life, stable clamping force and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

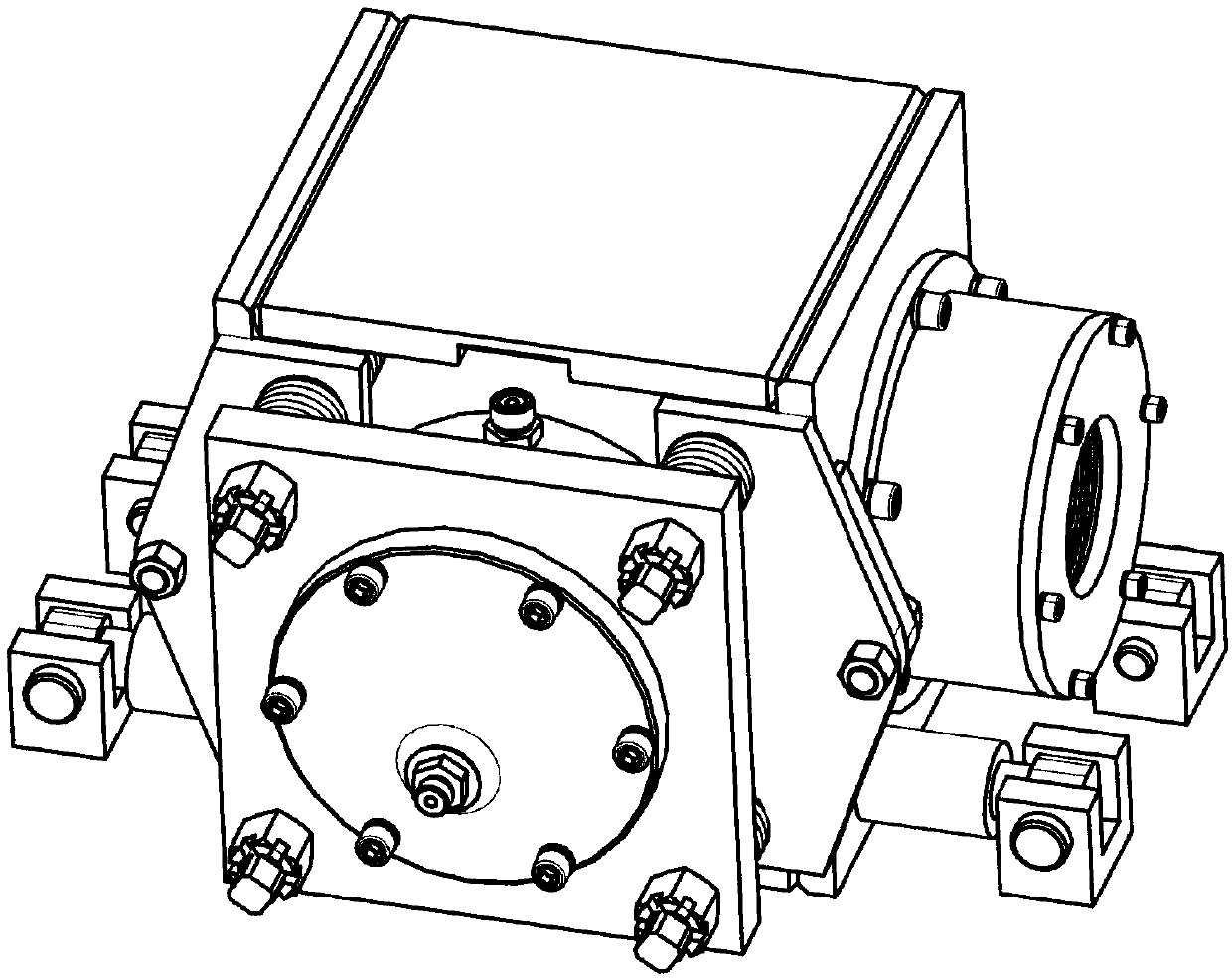

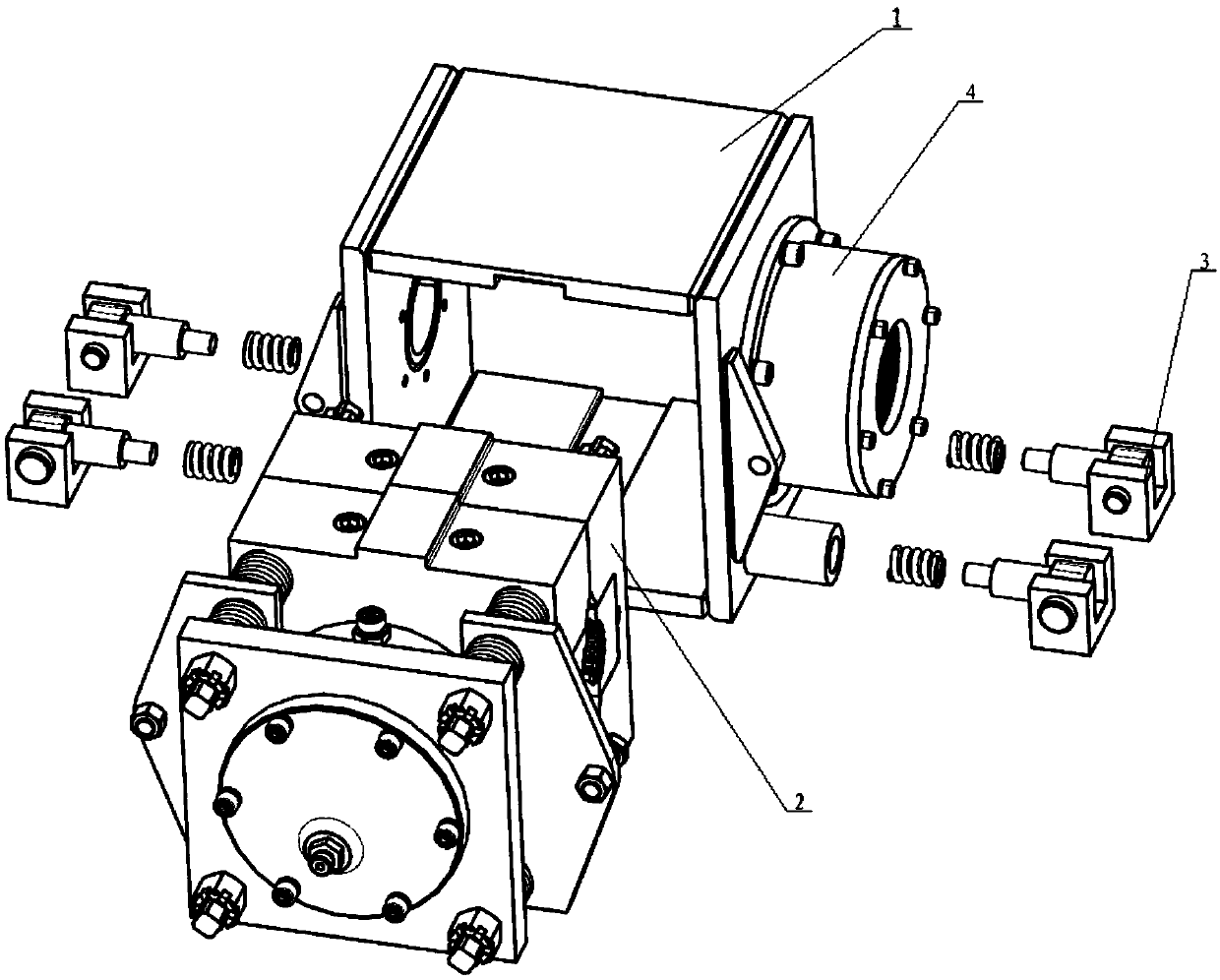

[0039] see Figure 1 to Figure 8 , shows the drill pipe clamping and stabilizing device with bidirectional position compensation function of the present invention.

[0040] see figure 1 and 2 , the drill pipe clamping and centralizing device with two-way position compensation function includes a main support body 1, a clamping assembly 2, an axial position compensation assembly 3 and a centralization assembly 4, the main support body 1 is a frame, and the clamping The tightening assembly 2 is detachably arranged in the main support body 1 to clamp the drill pipe, the centralization assembly 4 is located on an outer side of the main support body 1 for the centralization operation, and the axial position compensation assembly 3 is located at The two outer sides of the main support body 1 are used for axial position compensation.

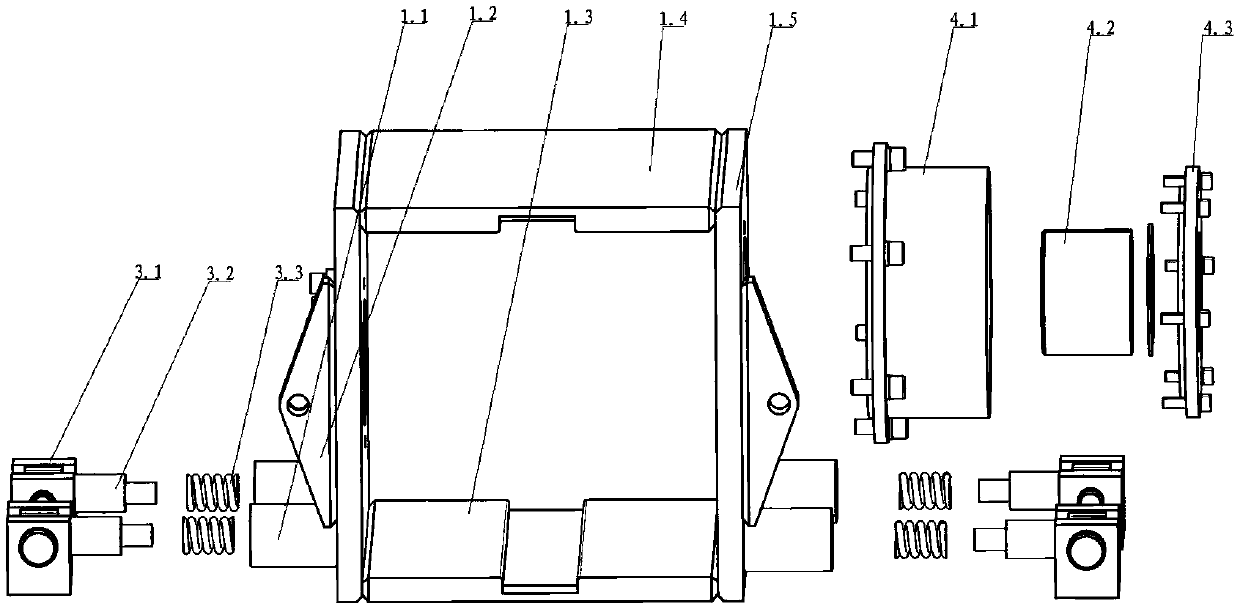

[0041] Among them, see image 3 It can be seen that the main support body 1 can include a support body bottom plate 1.3, a support body top plate ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap