Air conditioning system

A technology for air conditioning systems and heat exchangers, which is applied to lighting and heating equipment, irreversible cycle compressors, and compressors with reversible cycles, etc., which can solve the problem of limited space for the air supply aperture of the sliding vane and reduced efficiency of the main cylinder compression process. , It is difficult to supply gas with large flow and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

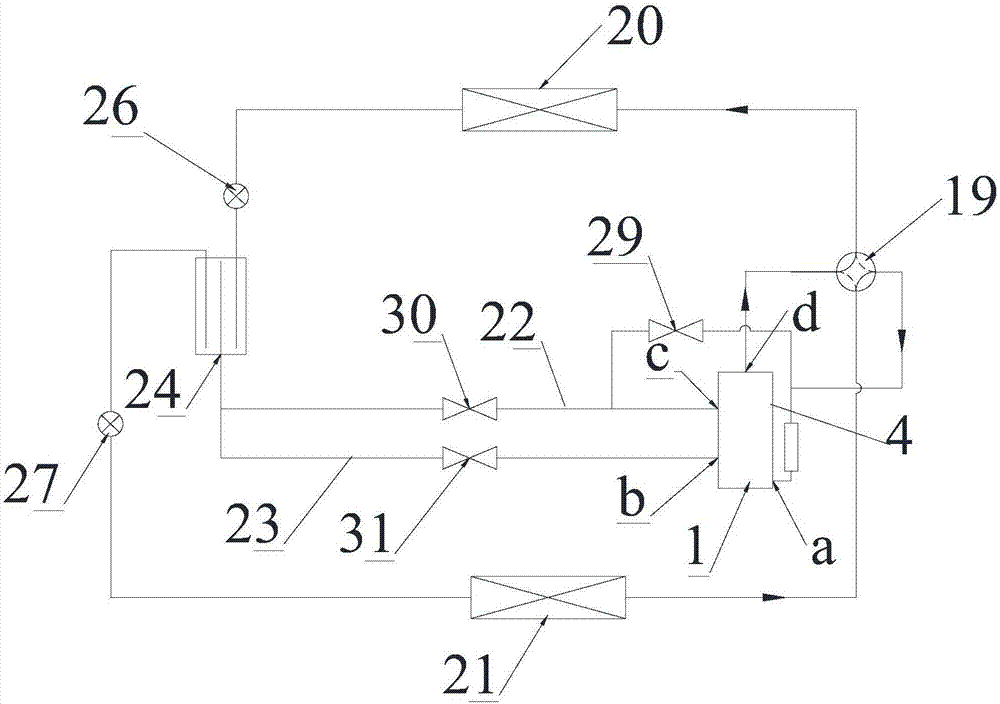

[0040] see in conjunction figure 1 As shown, according to the first embodiment of the present invention, the air supply device includes a first flasher 24, the inlet of the first flasher 24 is connected to the first heat exchanger 20, and the liquid outlet of the first flasher 24 is connected to To the second heat exchanger 21 , the gas outlets of the first flasher 24 are respectively connected to the first gas supply branch 22 and the second gas supply branch 23 .

[0041] After the refrigerant enters the first flasher 24, it is flashed by the first flasher 24 to form a large amount of gaseous refrigerant, and this part of gaseous refrigerant enters the compressor from the first gas supply branch 22 through the second suction port c , Supplement air to the compressor to increase enthalpy, improve the compression performance of the compressor, and improve the working performance of the air conditioner.

[0042] In the above embodiment, during the working process of the air co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com