Ice making control method and system and ice making machine

An ice-making control and ice-making machine technology, applied in the field of computer-readable storage media, can solve problems such as prolonging maintenance time, affecting user use, waste, etc., and achieves the effect of improving reliability and improving experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

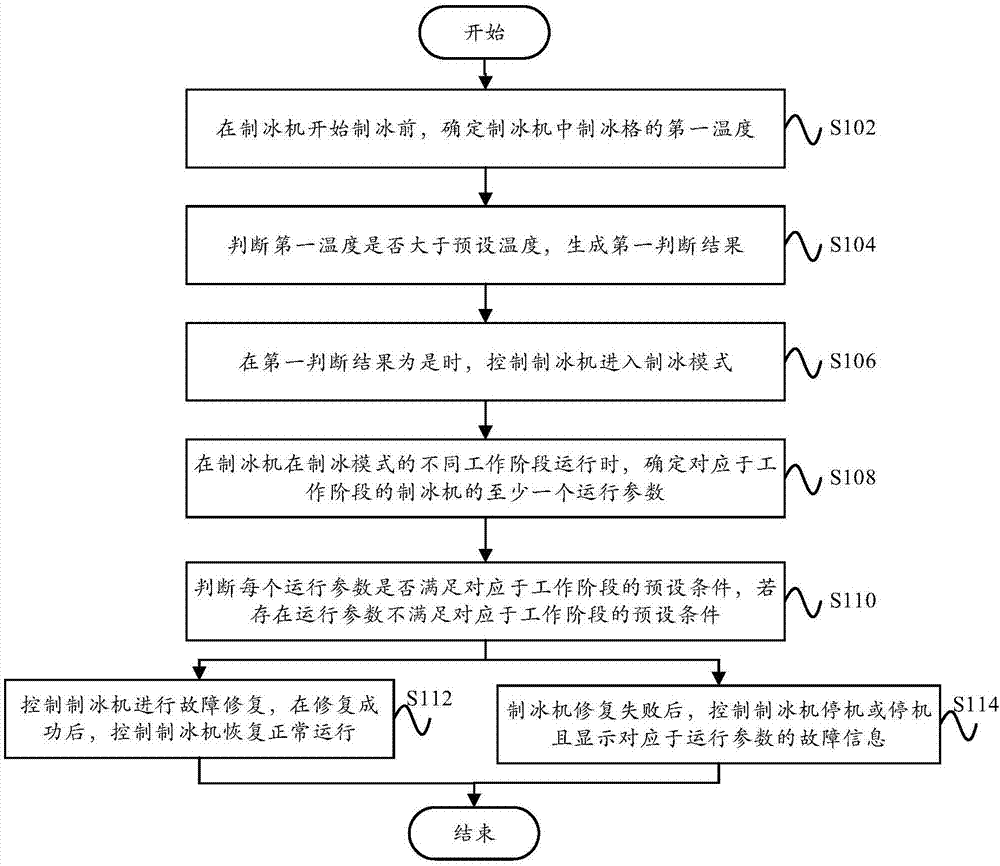

[0156] Such as Figure 8 As shown, it is the specific implementation steps of the ice making process of the ice maker: the ice maker judges whether the temperature of the ice making tray (the first temperature) is greater than 4 degrees Celsius (the preset temperature); it should be noted that the determination of the temperature is not only In order to detect the temperature of the ice making device and the ice cubes made, and to prevent the ice maker from being powered on again, when the temperature of the ice making tray is greater than 4 degrees Celsius, after entering the initialization process of the ice maker, the reset is completed and ice making starts ;Enter the ice-making cycle, and at the same time, if the temperature of the ice-making tray is not greater than 4 degrees Celsius, enter the ice-making cycle. Wherein, the ice making cycle corresponds to different working stages including but not limited to reset stage, ice making waiting stage, deicing stage and water...

specific Embodiment 2

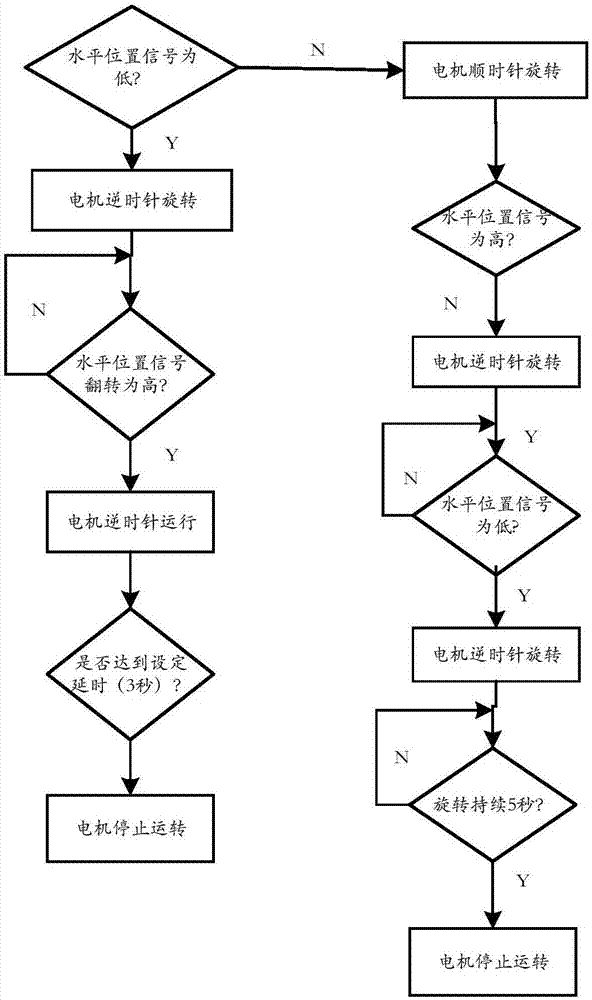

[0160] Such as Figure 9 Shown in the ice making cycle, ice machine motor failure judgment and emergency treatment methods, specifically: after the waiting time of the ice making cycle, the ice machine is powered on to reset or turn ice (from the ice stage) to rotate, and then make The ice machine motor is in the horizontal position detection, and the longest horizontal detection time is set. If the time limit is not exceeded and the horizontal position feedback signal cannot be detected, it will enter the water intake stage and be detected; if the time limit is exceeded and the horizontal position feedback signal cannot be detected, it is assumed that the ice stripper and the ice cube are frozen or ice appears Stuck and stopped. Then enter the first stage and heat up to the target temperature, then leave the ice again to judge whether the freezing has recovered, if not, start the abnormal reminder of motor movement; continue to enter the second stage and heat up to the targe...

specific Embodiment 3

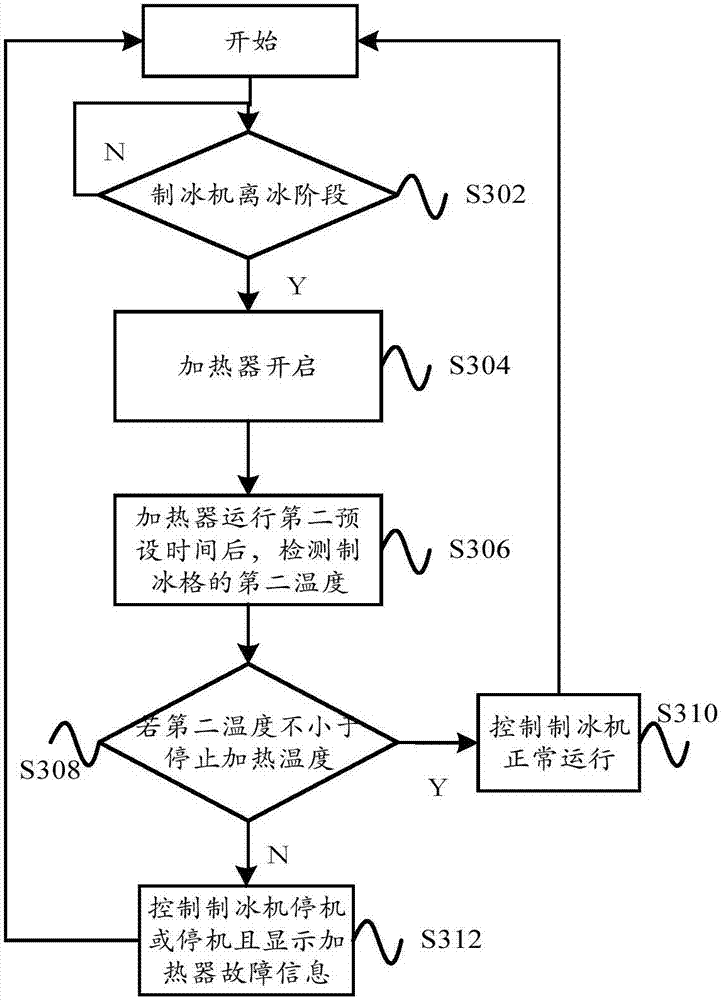

[0161] Such as Figure 11 As shown, it is a quick inspection method for system faults. The specific steps are as follows: make the ice machine mechanism not full of ice, and carry out the test; set the rapid ice machine fault diagnosis mode, and then the sensor reads the temperature and detects whether there is a fault; Specifically, whether the read temperature is within the operating range, and set / cancel the data of fault bit 1; then the ice machine rotates, reads the electrical signal corresponding to the horizontal position, determines whether the Hall feedback (electrical signal) is abnormal, and again Set the fast ice machine fault diagnosis mode, and set / cancel the data of fault bit 2; the ice machine continues to rotate, read the electrical signal corresponding to the horizontal position, and determine whether the Hall feedback (electrical signal) is abnormal. High (change), determine whether the heating component is abnormal, and set / cancel the data of fault bit 3; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com