Workpiece roughness detection device

A detection device and flatness technology, applied in measurement devices and instruments, using ultrasonic/sonic/infrasonic waves, etc., can solve the problems of high physical strength requirements of workers, worker fatigue, and large detection volume, so as to achieve a fast and simple detection process and simplify work. The process and operation are simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

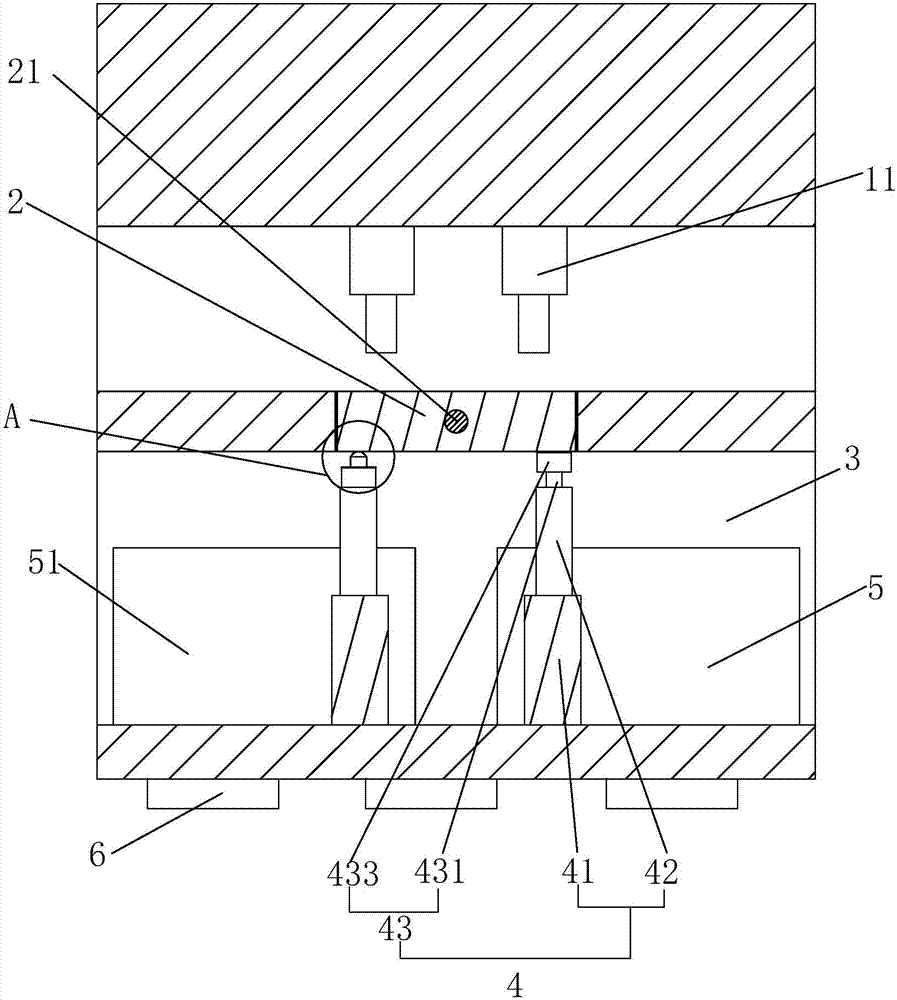

[0027] Embodiment: a kind of workpiece flatness detection device, such as figure 1 As shown, it includes a detection platform 1, a robot grasper (not shown in the figure) for realizing workpiece transportation, and a detection computer. On the detection platform 1, a detection board 2 for placing workpieces is provided, and a detection computer is provided in the detection board 2. The vibration sensor 21 connected to the circuit signal is located on the detection platform 1 directly above the detection board 2 and is provided with a driving device 11 connected to the detection computer circuit signal. The driving device 11 can realize linear motion up and down, and is placed on the detection board 2 The workpiece on the top generates pressure, and the driving device 11 can adopt a structure such as a combination transmission of a hydraulic cylinder, a DC servo motor, and a rack and pinion transmission mechanism.

[0028] Such as Figure 4 As shown, the detection computer inc...

specific Embodiment approach

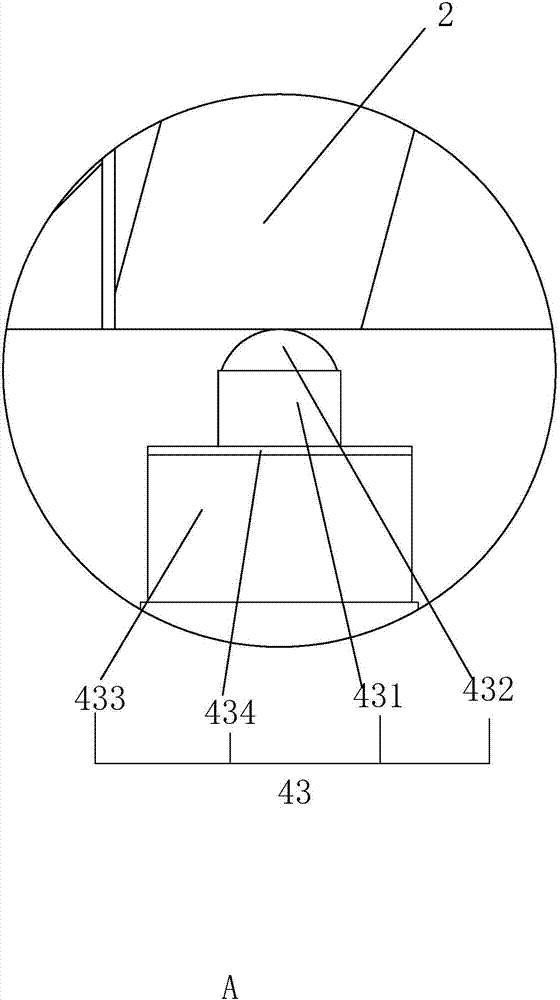

[0031] Specific implementation method: first control a plurality of power cylinders 41, make its telescopic rod 42 stretch out fully so that the detection plate 2 is in a state of being flush with the upper surface of the detection platform 1, and then the detection computer controls the electromagnet 434 to work, so that the support sleeve The upper surface of 433 is adsorbed and contacted with the bottom of the detection board 2 to form a support for the detection board 2, so that the detection board 2 is placed stably in a horizontal state. At this time, the workpiece to be detected is placed on the detection board 2 by the manipulator, and the driving device is controlled. 11 works, the control module in the detection computer transmits a pressure value signal to the drive device 11, the drive device 11 works and applies a certain pressure to the workpiece, and the pressure value is the pressure value set in the detection computer.

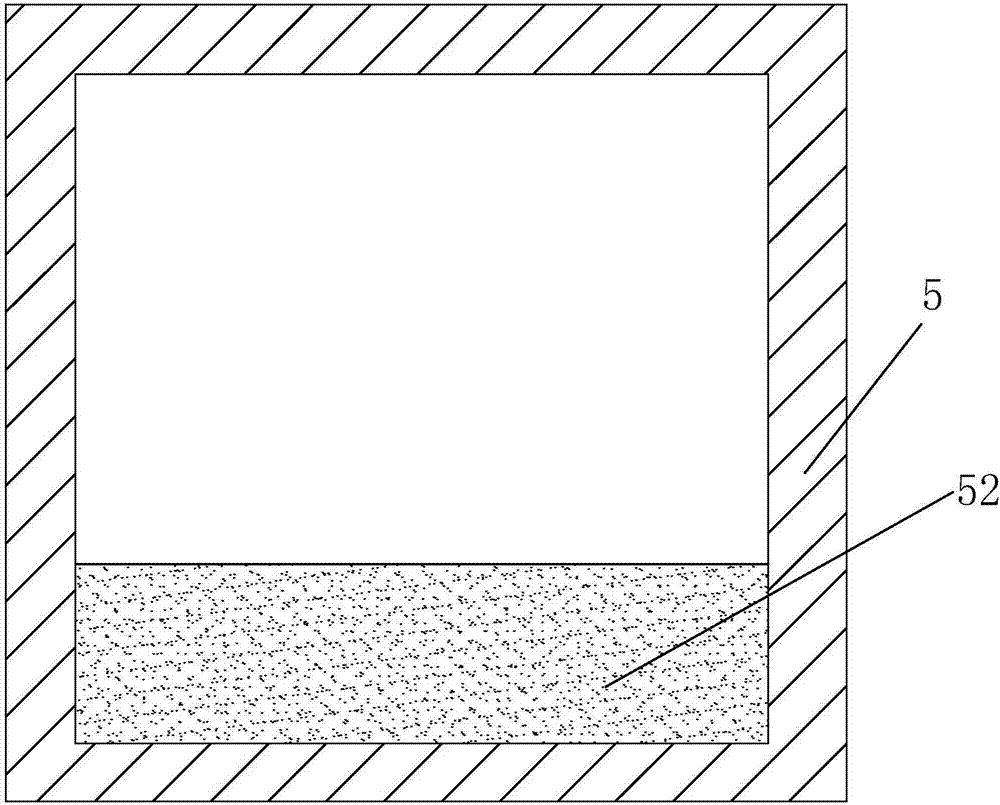

[0032] Such as Figure 5 with 6 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com