320t torpedo car axle box temperature measurement system

An axle box and mixed-rail car technology, applied in the field of detection, can solve the problems of long detection time, damaged axle box bearings, and untimely inspection, and achieve the effect of efficient detection and timely reporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

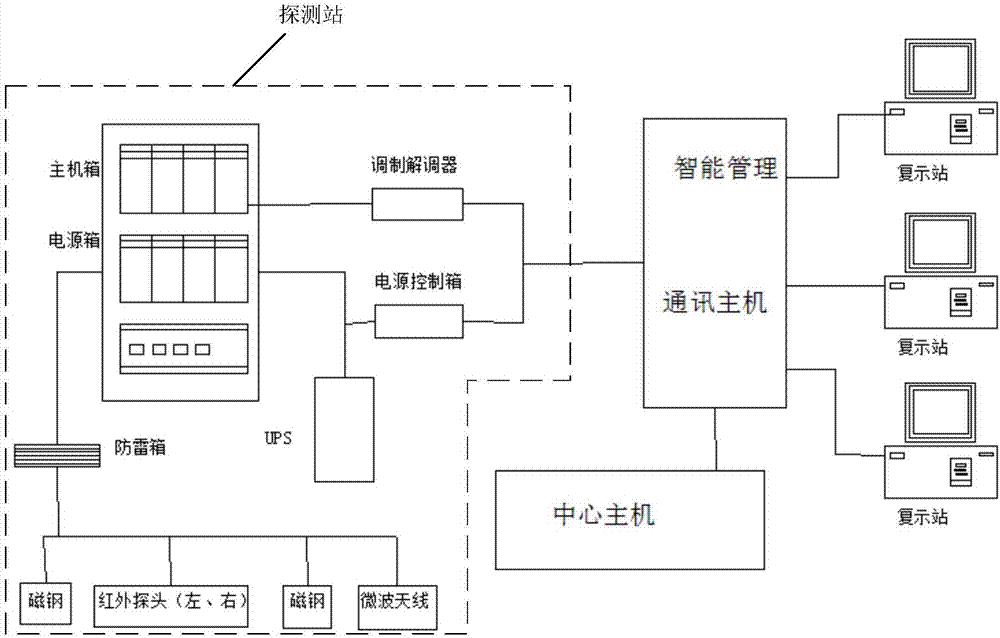

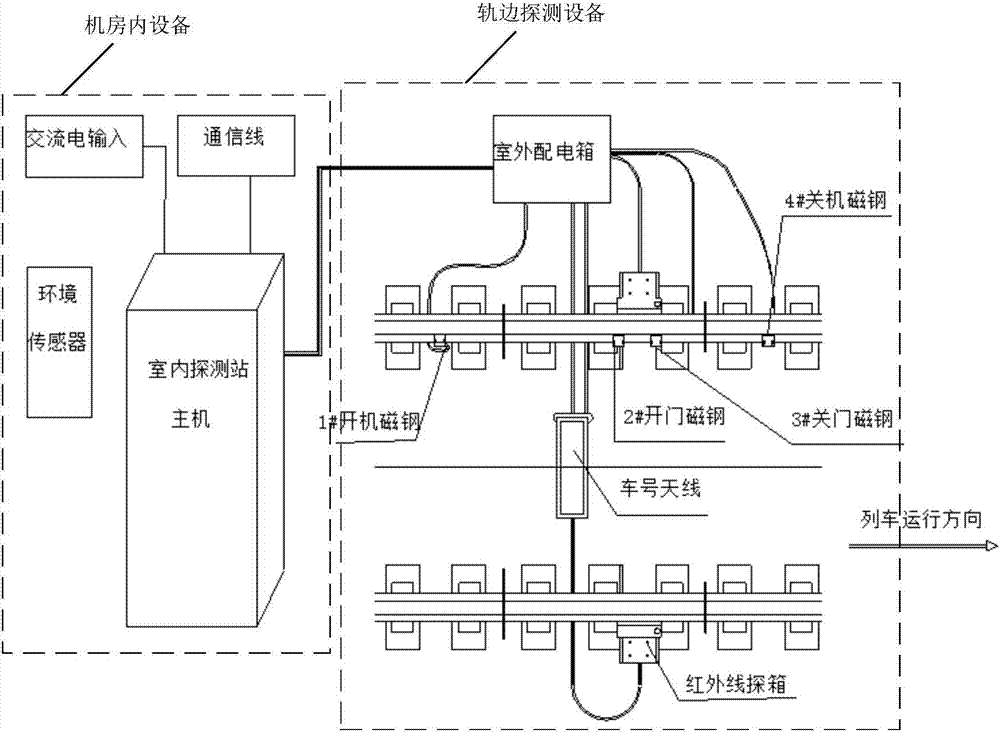

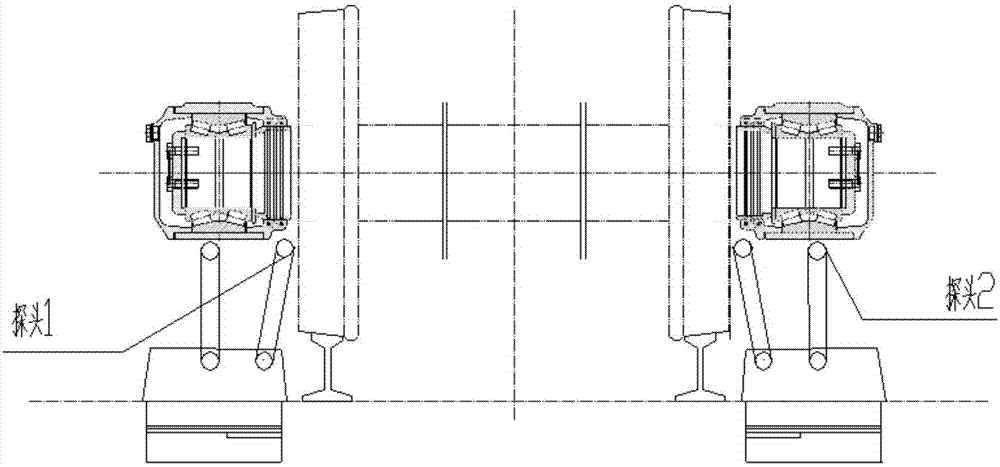

[0025] The embodiment of the present invention provides a 320t mixed iron axle box temperature measurement system, which is used to realize the timely and efficient detection of the axle box temperature of the 320t mixed iron car.

[0026] In order to solve the above technical problems, the general idea of the technical solution provided by the present invention is as follows:

[0027] In the technical solution of the embodiment of the present invention, the trackside detection equipment of the detection station is set on the traveling line of the 320t mixed railway car, so that the temperature of each axle box can be detected in a timely and efficient manner when the 320t mixed railway car passes the traveling line , the trackside detection equipment is connected to the equipment in the machine room of the detection station, and the repeat station receives the temperature of each axle box of the 320t mixed iron car detected and sent by the trackside detection equipment throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com