Magnetic switch for powering on and off an autonomous underwater vehicle

An underwater robot, power on and off technology, applied in the direction of electric switch, magnetic/electric field switch, circuit, etc., can solve the threat to personal safety and other problems, achieve the effect of improving safety factor, good versatility, and avoiding misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

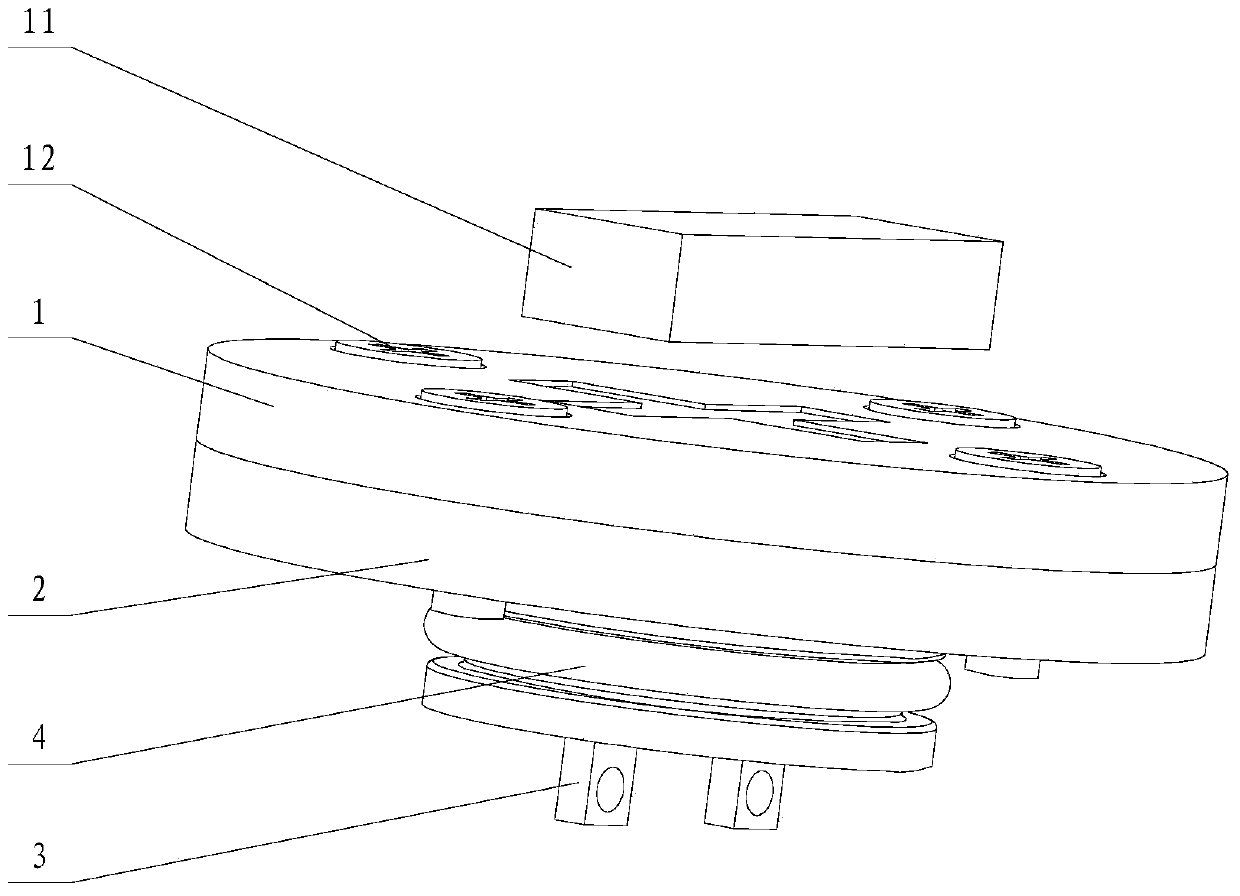

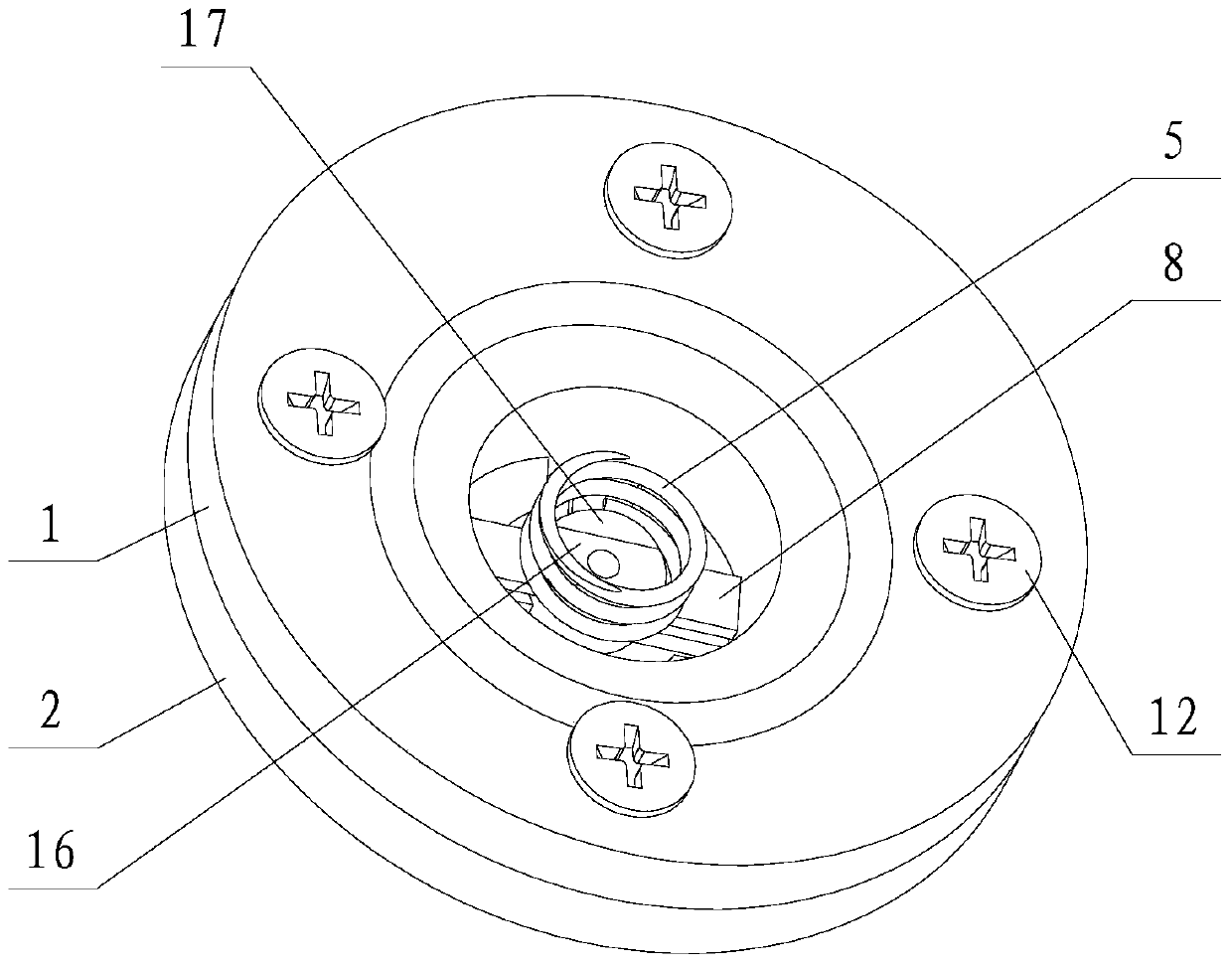

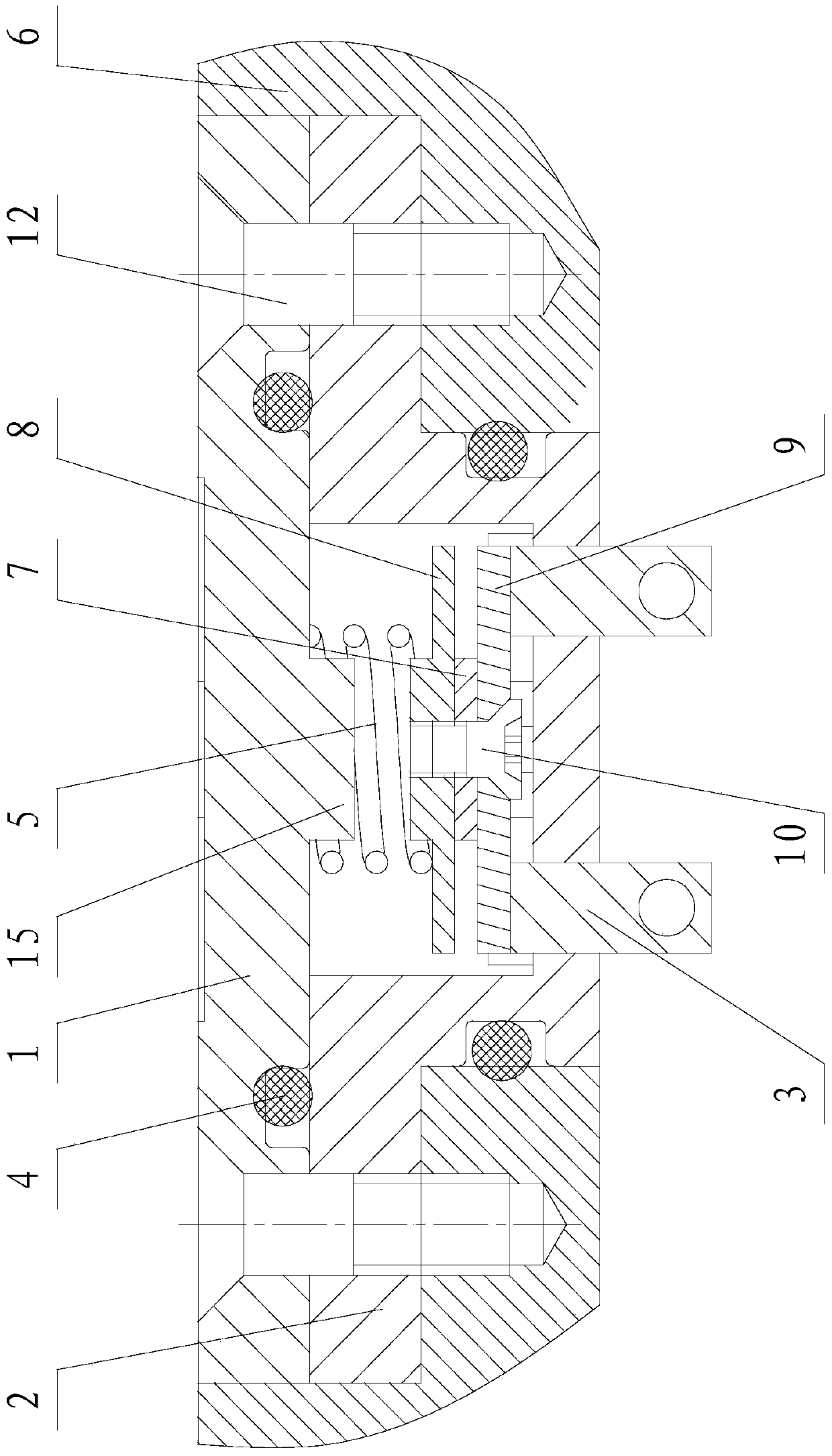

[0028] Such as Figure 1~6 and Figure 8 As shown, the present invention includes a loam cake 1, a base 2, a contact 3, an elastic component, a connector 7 and a bar magnet 11, wherein the base 2 is installed on the body 6 of an autonomous underwater robot through a screw 12, and is connected by an O-shaped The sealing ring 4 is sealed to ensure the tightness of the magnetic switch and the body 6; different bases 2 can be designed for different shapes of the body 6, and the base 2 of the present embodiment is in the shape of a disc, with accommodating connectors 7 and 6 in the middle. Cavities for elastic components. The upper cover 1 is disc-shaped, fixedly connected to the base 2 by screws 12, and the upper cover 1 and the base 2 are also sealed by an O-ring 4 to ensure the sealing of the magnetic switch. The connecting piece 7 is cylindrical and accommodated in the cavity in the base 2 . The upper and lower ends of the connecting piece 7 are respectively provided with U-s...

Embodiment 2

[0033] Such as Figure 7 As shown, the difference between the present embodiment and the first embodiment is that there is a groove on the connector 7 of the present embodiment, and the steel sheet 8 is replaced by a magnet 20; 7 is fixed, and magnet 20 and copper sheet 9 are cuboid shape. The lower surface of the upper cover 1 is provided with a convex body B15, which has a hole 18 in the middle of the convex body B15, and the upper surface of the connector 7 is provided with a guide post 19 inserted into the hole 18, and the two ends of the spring 5 are respectively sleeved on the convex body. On the B15 and the guide post 19, when the bar magnet 11 attracts the magnet 20, the guide post 19 moves up and down in the hole 18 to play a guiding role. Others are all the same as in Embodiment 1.

[0034] Working principle of the present invention is:

[0035] When the autonomous underwater robot needs to be powered on land or in water, the staff put the bar magnet 11 close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com