Control method, control device, yogurt machine and refrigerator for yogurt preparation

A control method and control device technology, applied in milk preparations, dairy products, applications, etc., can solve the problems of long production time, long time consumption, monotonous heating mode, etc., and achieve the goal of increasing functionality, reducing energy consumption, and reducing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0207] Specific embodiments: a yogurt machine, including a heating wire, a temperature sensor and an LED display light, wherein the temperature sensor is arranged inside the yogurt machine for detecting the temperature in the cavity. The yogurt machine can be embedded in the refrigerator, specifically embedded in the upper shelf of the door body of the box, and can also work independently from the refrigerator.

[0208] After the yogurt machine is powered on, the program enters the initialization state, resets all parameters, starts the timer and AD acquisition channel, etc., enters the standby state, and waits for key input. This control mode is divided into three types:

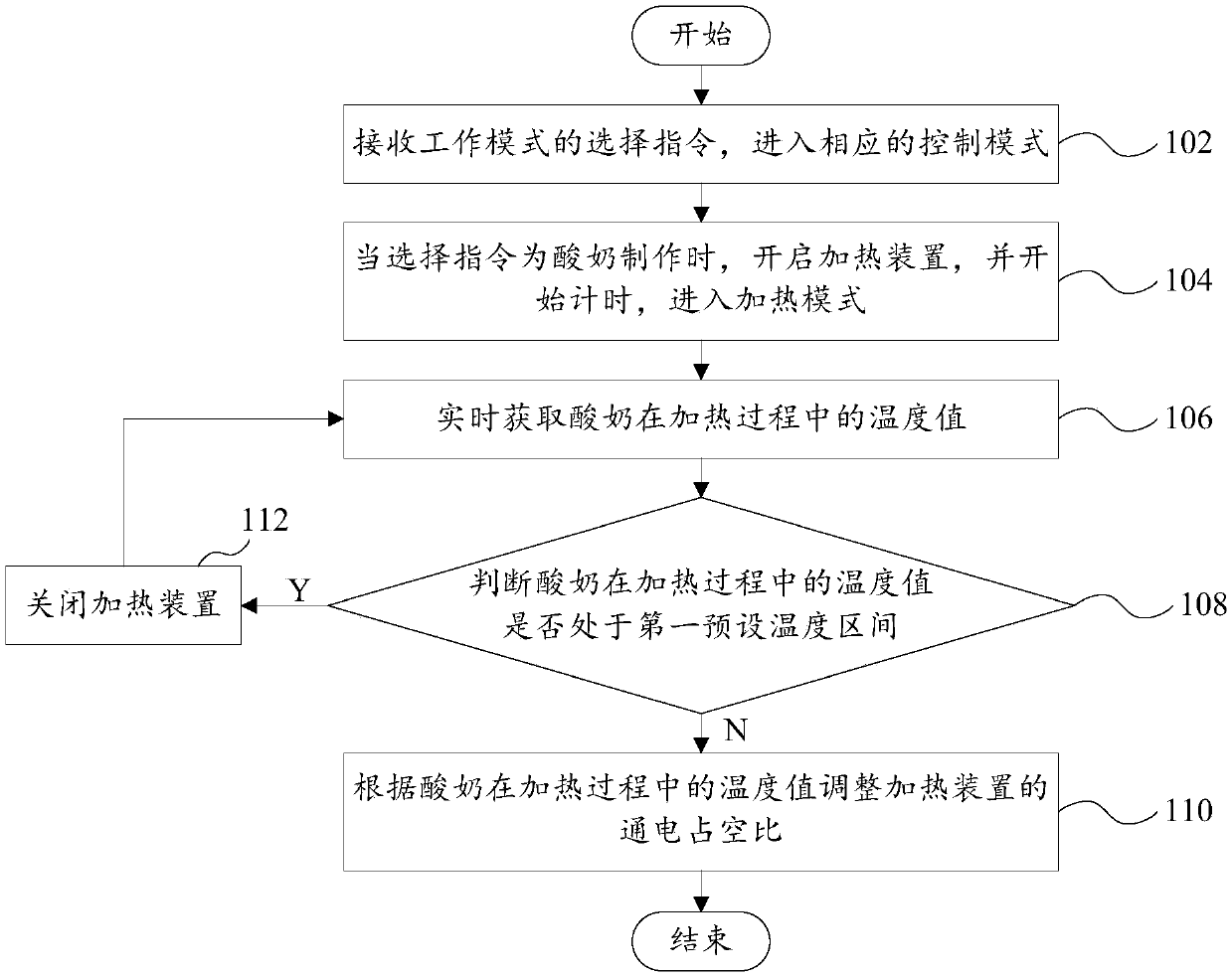

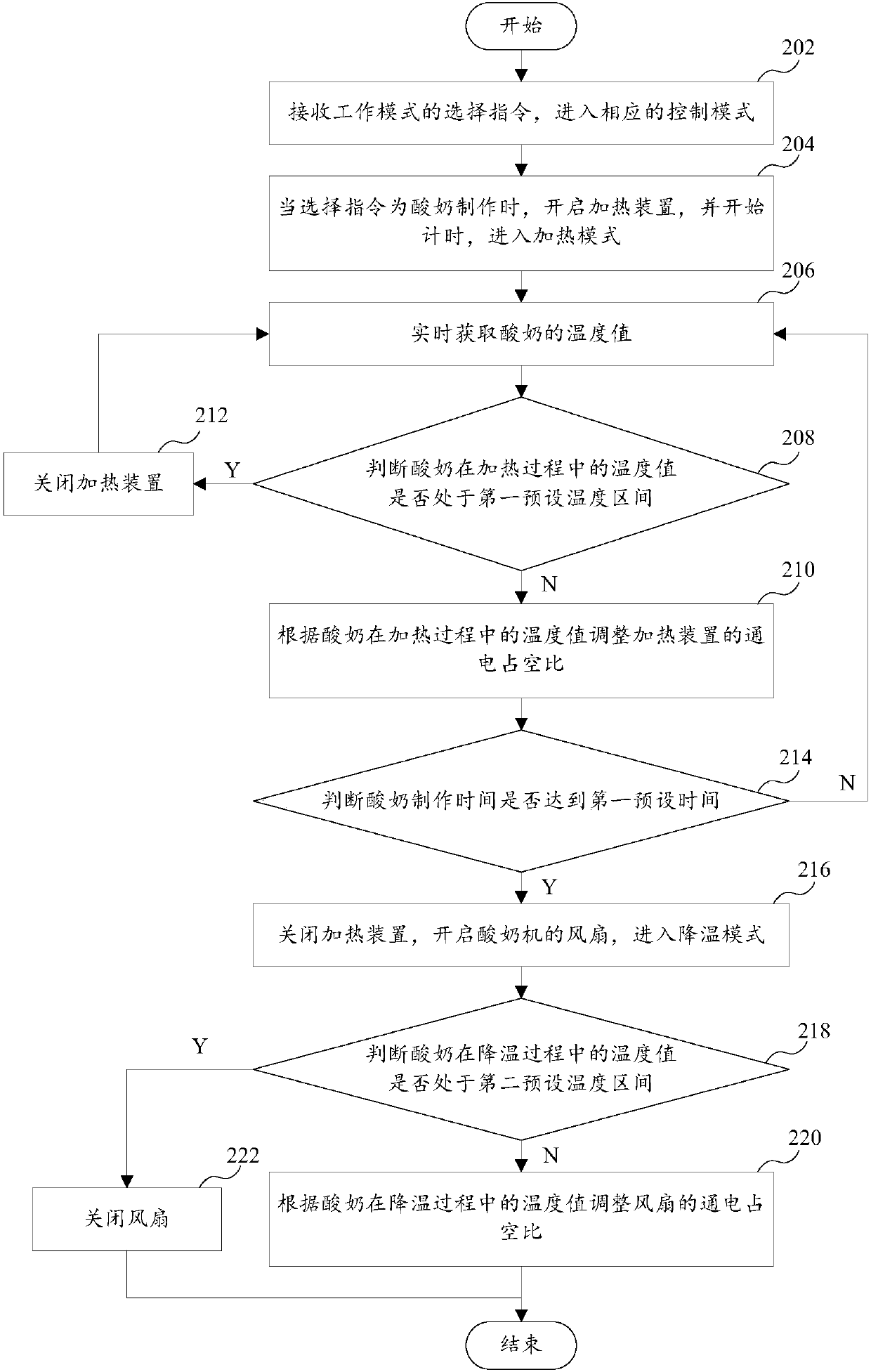

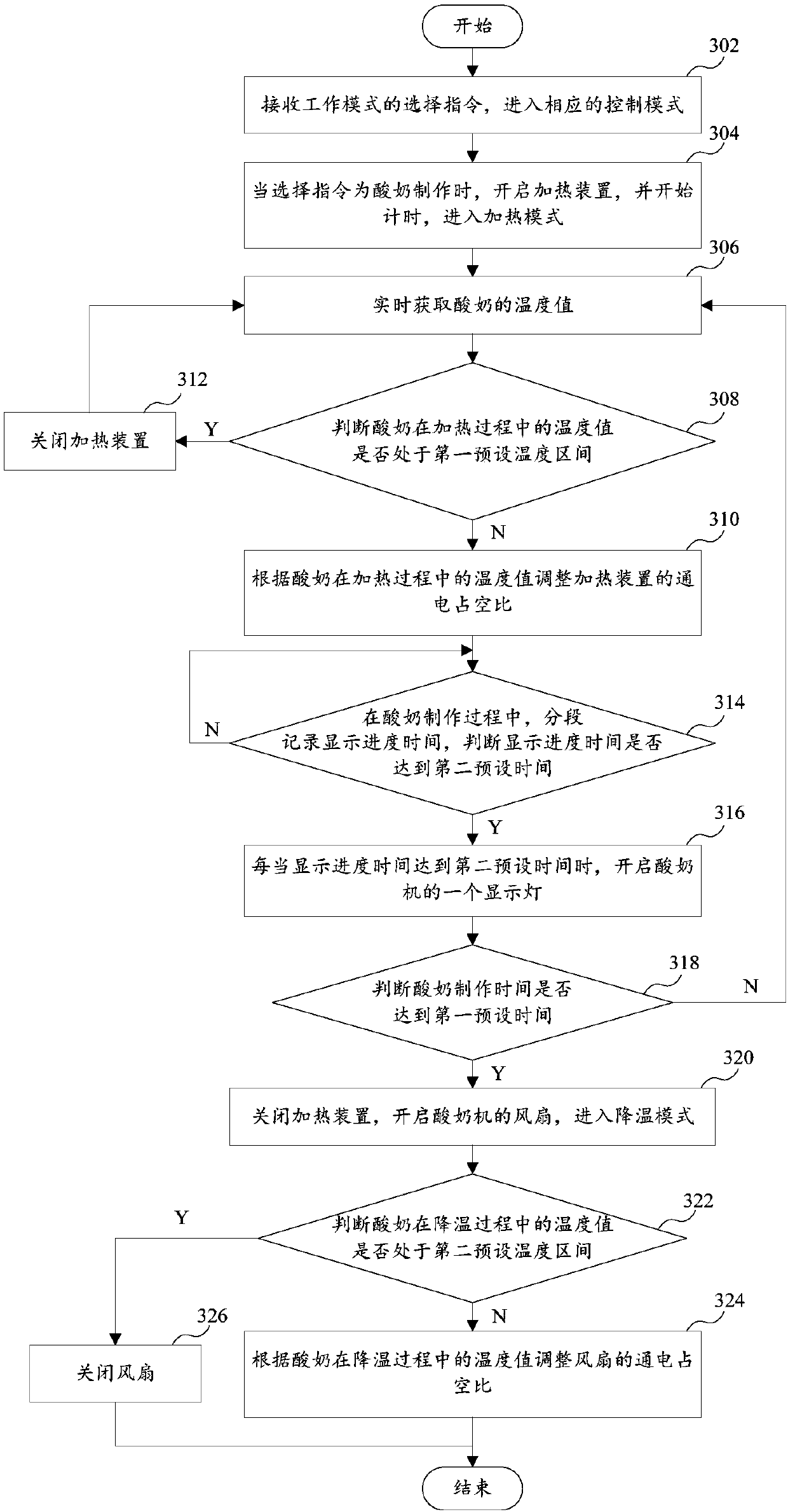

[0209] 1. Yogurt production mode (heating mode). In this mode, firstly start the timer function, then start the PWM timer, turn on the heating wire, and enter the pulse heating mode. At the same time, the AD channel continuously collects the value of the sensor, which is consistent with Tm1 , Tm2 for compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com