Constant-temperature tealeaf parching machine

A technology of tea frying machine and constant temperature, which is applied in the direction of tea processing before extraction, can solve the problems of low work efficiency, unevenness, easy frying and coke frying, etc., and achieves the effects of reducing labor, good tea quality and uniform heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

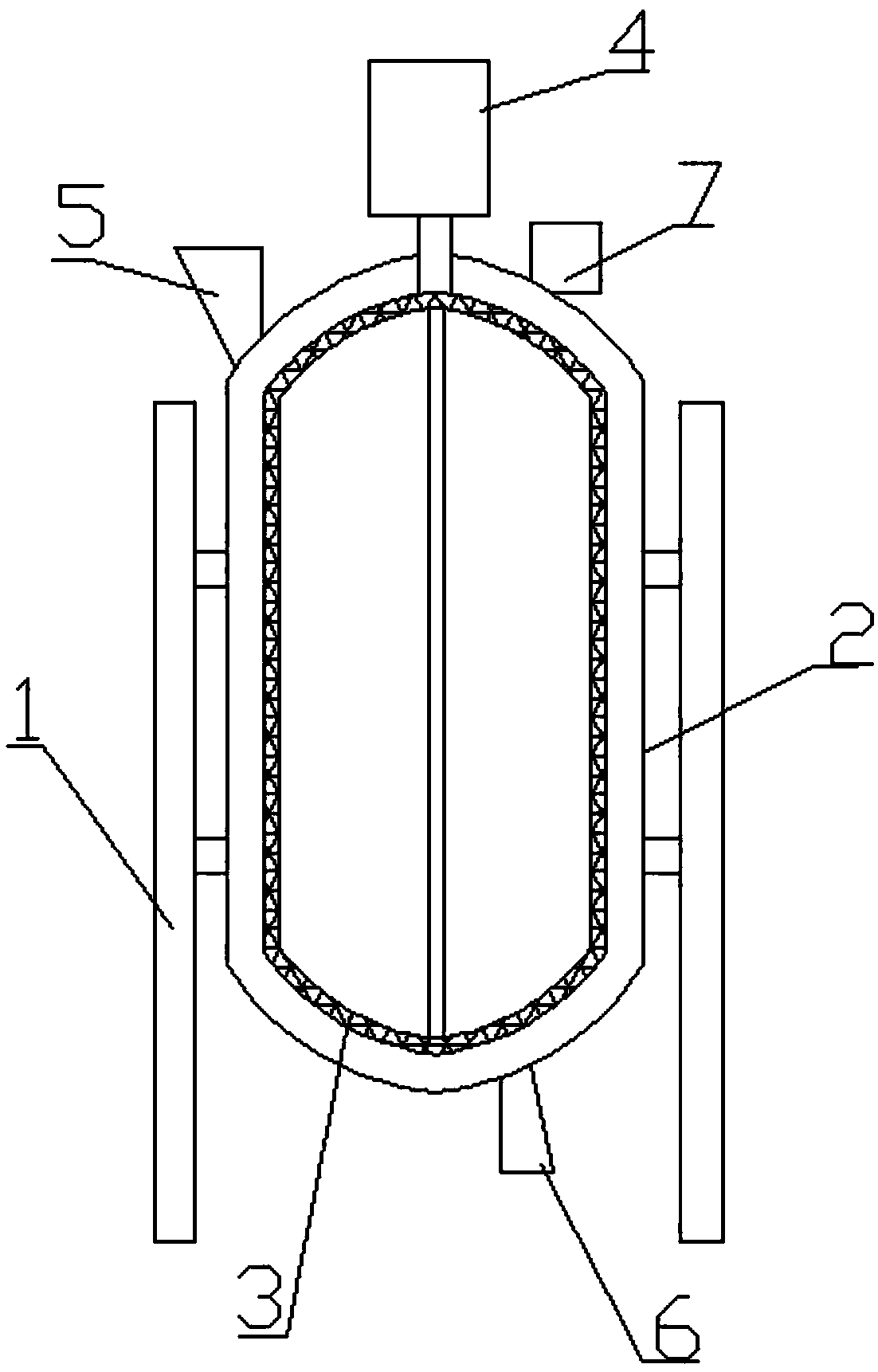

[0016] Such as figure 1 As shown, the constant temperature tea frying machine includes a frame 1, and a tea frying pot 2 is arranged on the frame. The tea frying pot includes a cylinder, and hemispheres are arranged at both ends of the cylinder. The body is vertically arranged, and it is fixed on the frame by the hoop. The tea frying pot has two layers, and the outer layer is provided with a heat insulation layer. A cavity is formed between the two layers. There is a fan at the bottom of the outer layer of the frying tea pot. , the fan is connected with the heat generating device, pumps various hot air into the cavity to heat the tea leaves, a pipe is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com