Glycol jetting and fusion-promoting device for anti-freezing liquid production equipment

A production equipment, ethylene glycol technology, applied in fluid mixers, chemical instruments and methods, dissolution, etc., can solve the problem of high frequency of antifreeze replacement, achieve the effect of improving overall uniformity, promoting fusion, and improving overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

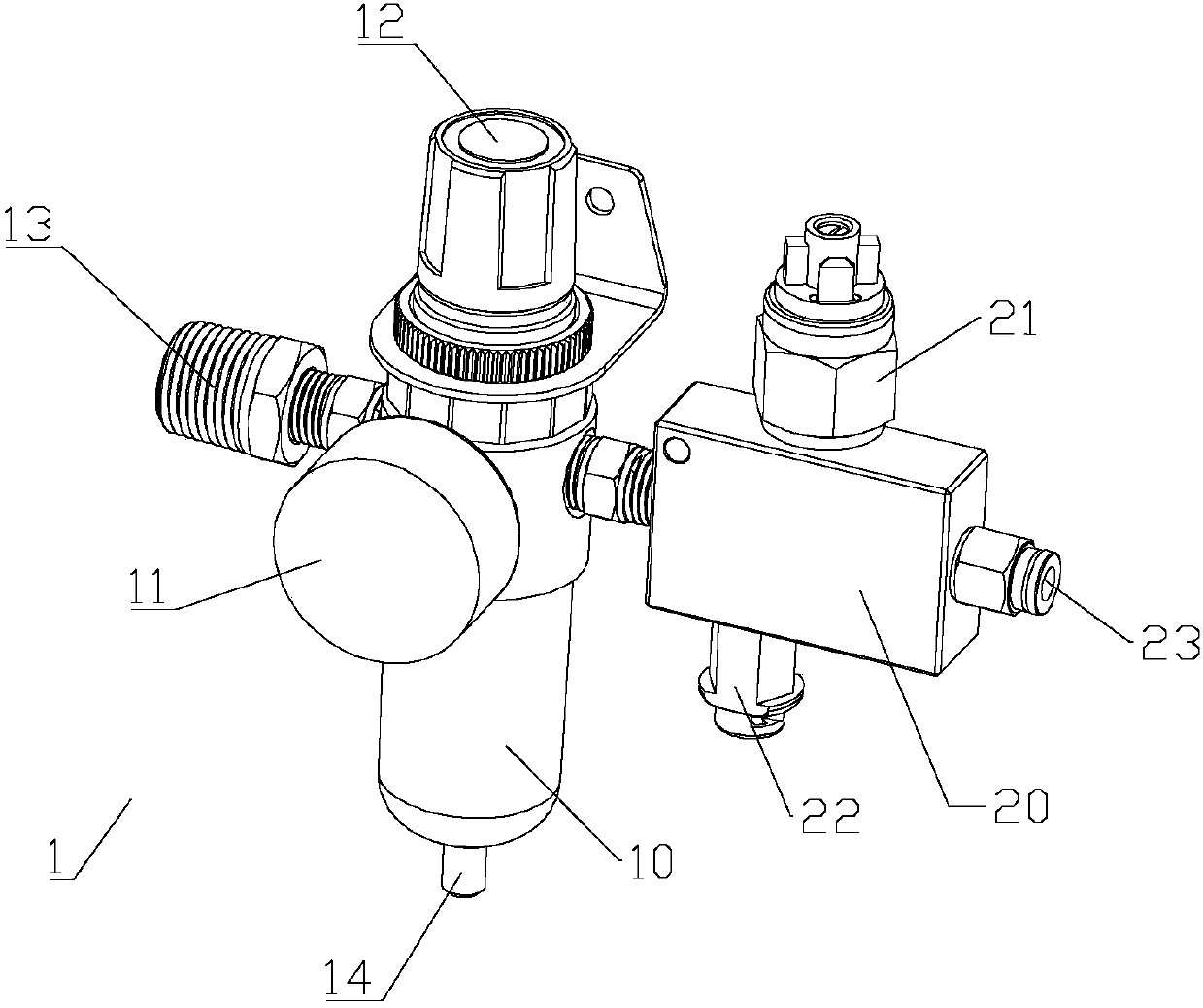

[0012] Such as figure 1 As shown, a kind of antifreeze production equipment ethylene glycol injection accelerator 1 comprises a booster cylinder 10, an air inlet 13 is provided on the booster cylinder 10, a flow control knob 12 is provided on the booster cylinder 10, and the flow rate The control knob 12 is used to control the air intake flow of the air inlet 13. The booster cylinder 10 is provided with an air pressure gauge 11, and the booster cylinder 10 is also provided with an overpressure protection valve 14. The booster cylinder 10 and a foaming cylinder 20 Connected, the inner cavity of the foaming cylinder 20 is provided with multi-layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com