Mixing, forming and instrument cleaning integrated device for cement mortar test piece

A cement mortar and mixing device technology, which is applied in the direction of cement mixing device, unloading device, clay preparation device, etc., can solve the test results that affect the strength and shrinkage performance of cement mortar, affect the normal progress of the test, and increase the difficulty of cleaning the mixing pot to avoid waste and evaporation of water, save manpower, and improve the safety of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

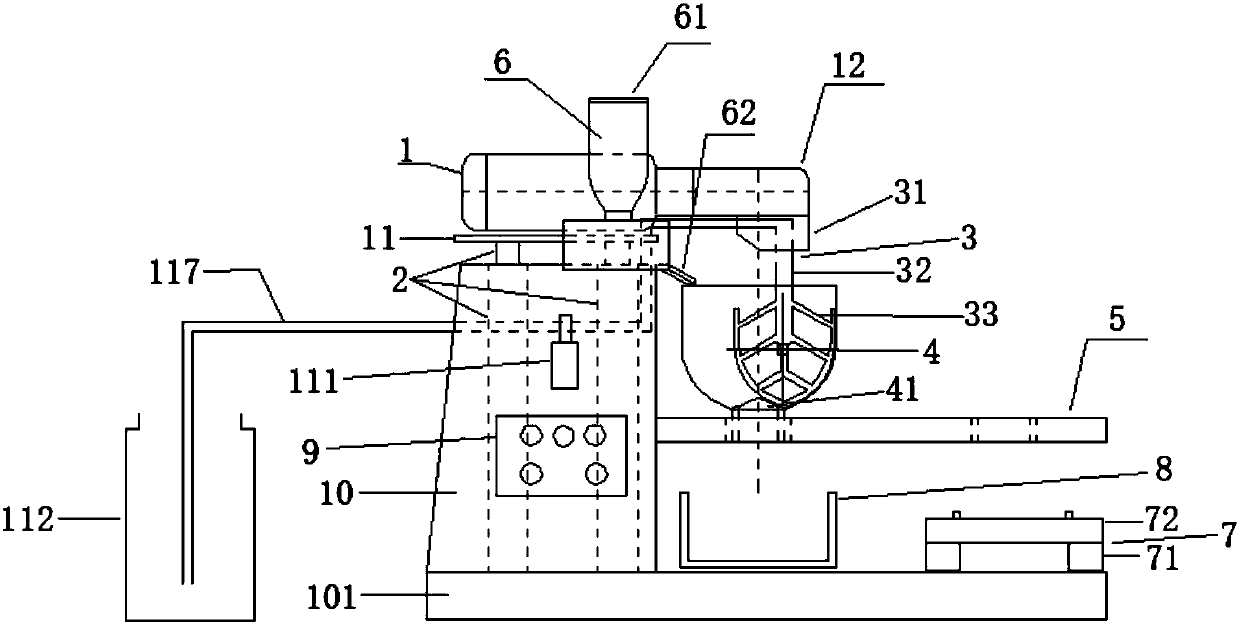

[0041] see Figure 1 to Figure 7 , the present invention comprises a frame 10 and a vibrating device for installing a forming mold. A motor 1 is installed on the frame 10 through a lifting device 2, wherein the motor 1 is fixed on a first base 11, and the lower side of the first base 11 is connected to the first base 11. The upper end of the lifting device 2 is connected, the lifting device 2 is embedded in the frame 10 and the lower end of the lifting device 2 is fixed on the second base 101, the first base 11 is located above the frame 10, and the frame 10 is fixed on the second base 101 . The lifting device 2 adopts a hydraulic lifting device.

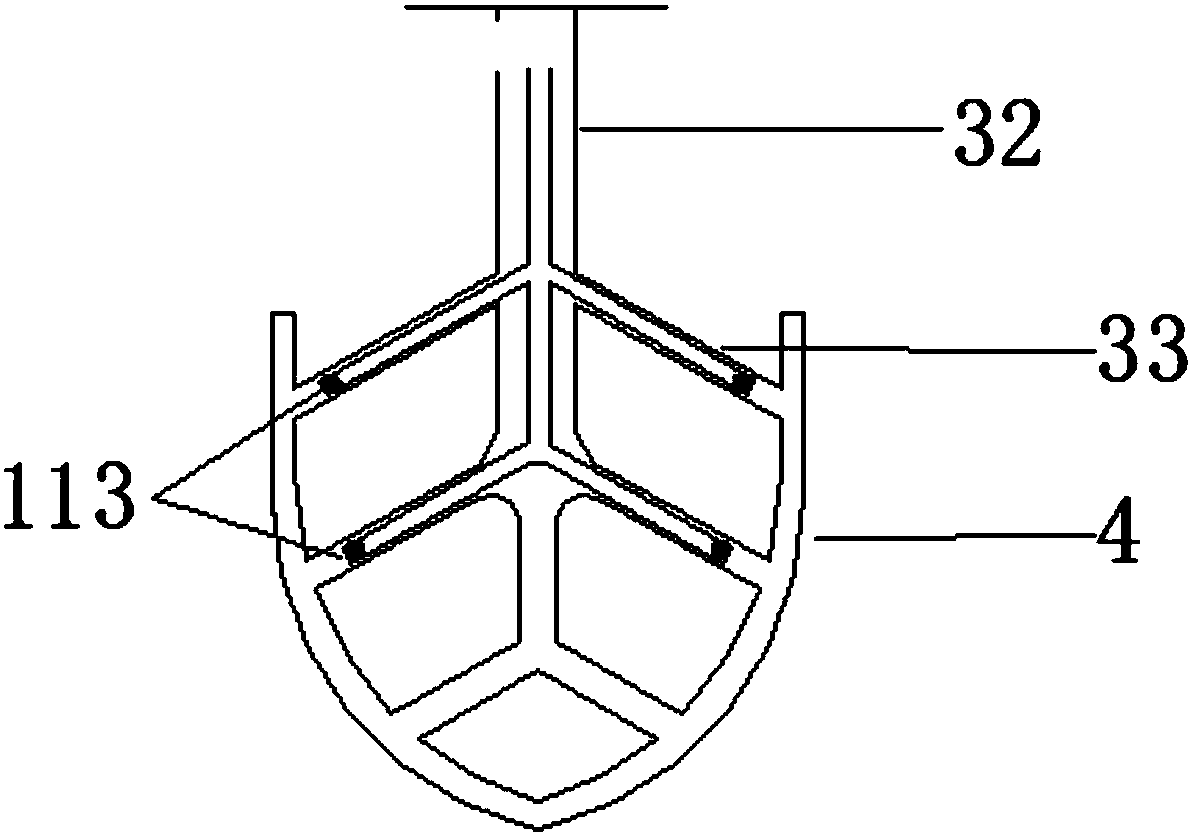

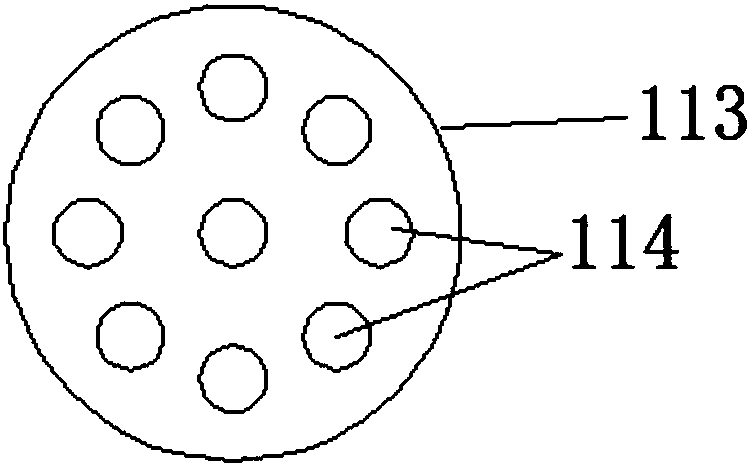

[0042] The motor 1 is connected to the stirring device 3 through the steering transmission mechanism 12. The stirring device 3 is also provided with several cleaning ports 113. The cleaning ports 113 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com