Aluminum honeycomb panel and edge sealing method thereof

A technology of aluminum honeycomb and honeycomb panel, which is applied in the field of plate structure, can solve problems such as difficult industrial production, difficult processing, and staying in the experimental stage of small batches, so as to protect forest tree resources, meet decoration needs, and have rich and diverse colors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

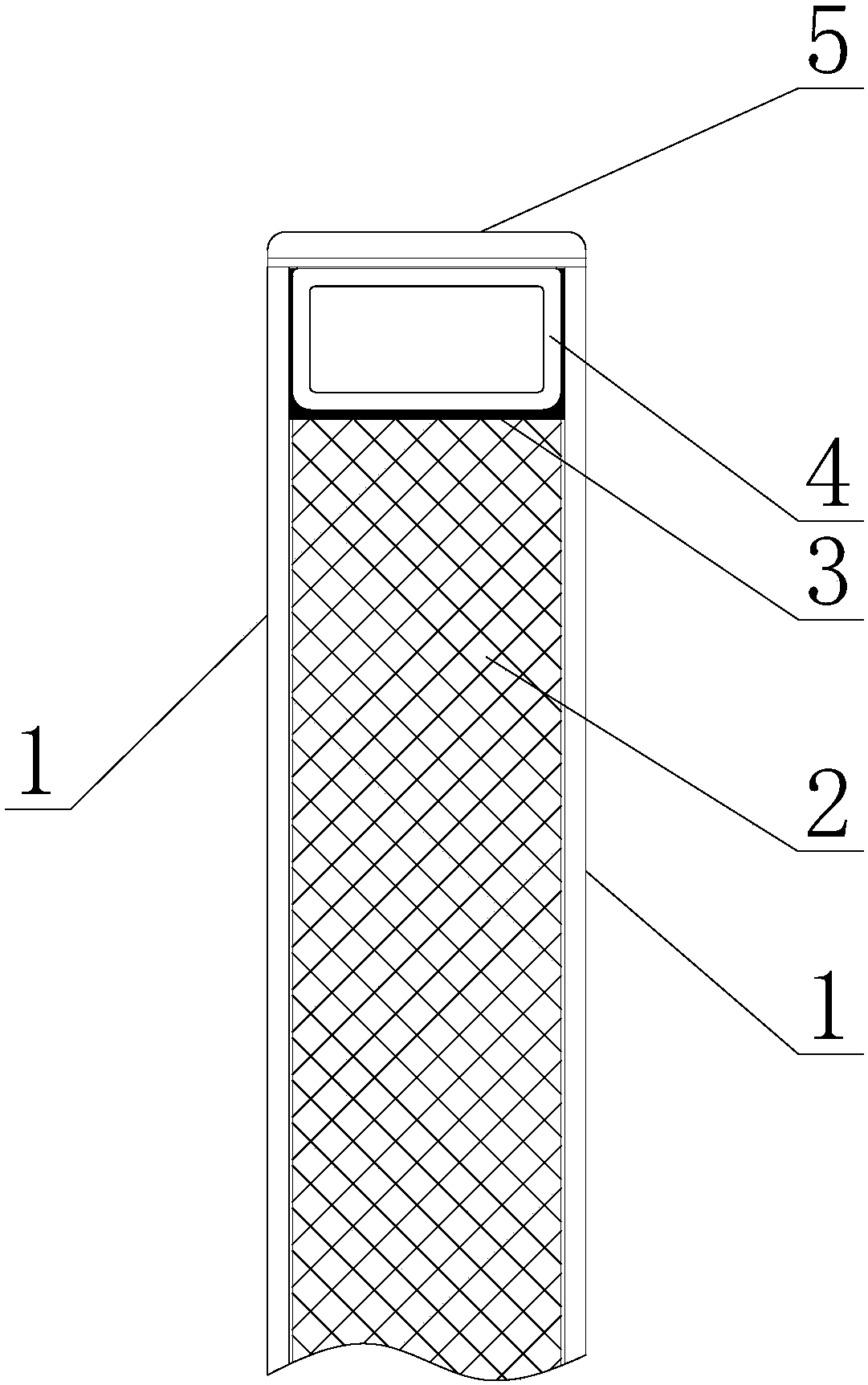

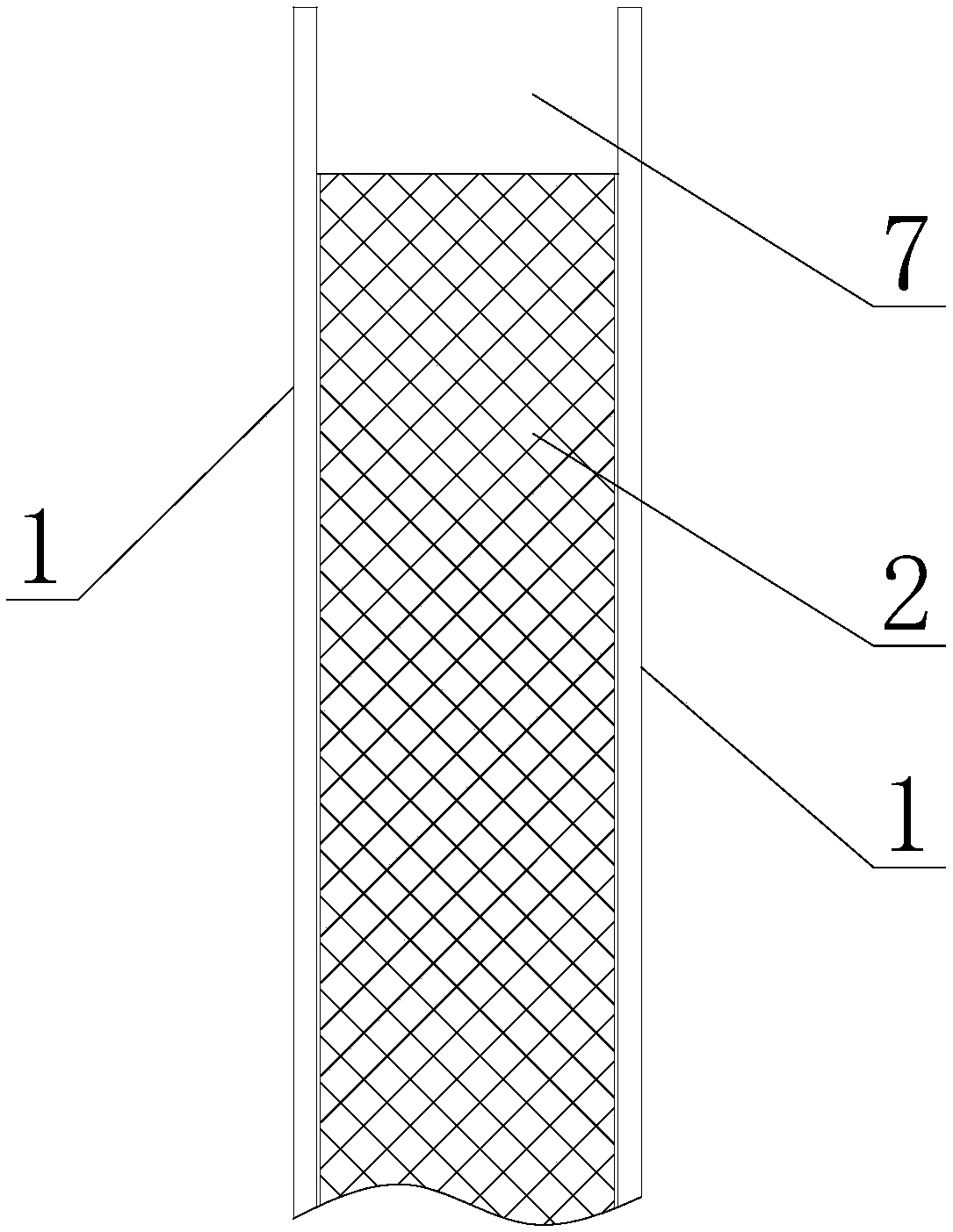

[0037] Such as figure 1 , an aluminum honeycomb panel, including a honeycomb core 2 and an aluminum plate 1 laid on both sides of the honeycomb core 2, and also includes an inner sealing strip 4 and edge sealing parts, such as image 3 A groove 7 is formed at the connection between the top of the honeycomb core 2 and the two aluminum plates 1, the cross-sectional profile of the inner seal 4 is rectangular, and the rectangular inner seal 4 is connected to the inner seal 4 through an adhesive layer 3 In the groove 7, the edge seal is connected to the inner seal 4; the cross-sectional size of the inner seal 4 is the same as the cross-sectional size of the groove 7; the honeycomb core 2 is aluminum honeycomb or Grid-like structure.

[0038] The edge sealing piece is a PVC edge sealing strip 5 .

[0039] The PVC edge sealing strip 5 is bonded on the top surface of the inner sealing strip 4 .

[0040] The inner seal 4 is a hollow cylinder structure or a structure filled with hone...

Embodiment 2

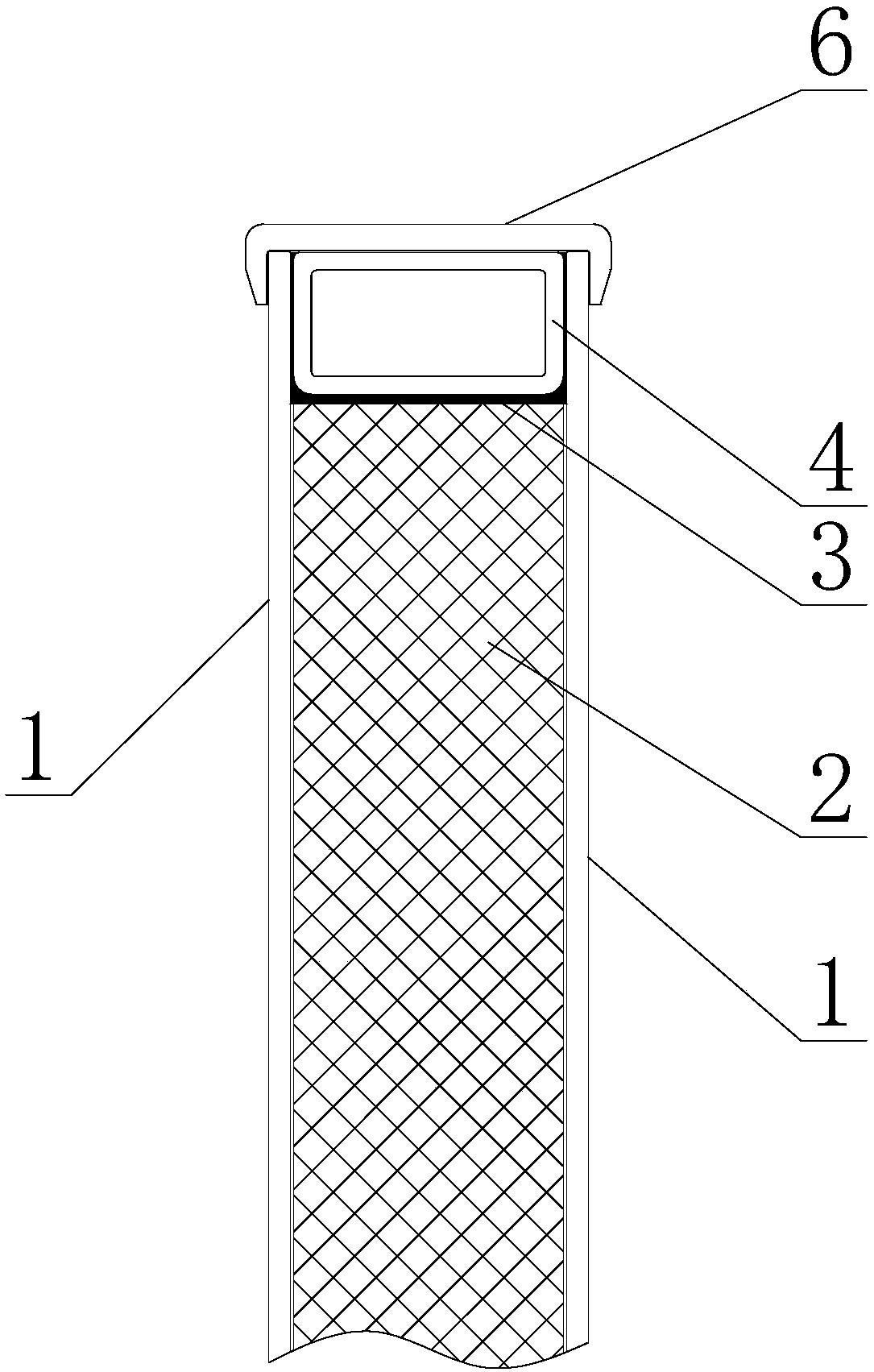

[0049] Such as figure 2 , different from Example 1, the edge banding piece is an aluminum alloy outer edge banding strip 6.

[0050] The aluminum alloy outer edge strip 6 is bonded to the top surface of the inner seal 4 , and both ends of the aluminum alloy outer edge strip 6 are bent and abutted against the aluminum plate 1 .

[0051] The edge sealing method of the aluminum honeycomb panel of the present embodiment:

[0052] a. Bonding and compounding the aluminum plate 1 and the inner interlayer into a basic aluminum honeycomb panel;

[0053] b. Grooving the four sides of the basic aluminum honeycomb panel to form the groove 7;

[0054] c. Embed the inner seal 4 in the groove 7 with adhesive glue, and ensure that the surroundings of the aluminum honeycomb panel are flush;

[0055] d. Adhere the aluminum honeycomb panel with an aluminum alloy outer wrapping edge strip 6 , and abut the bent parts at both ends on the aluminum panel 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com