Liquid container

A liquid container and liquid technology, applied in the field of machinery, can solve the problems of waste of bottom space, puncture or damage of the inner bag, liquid leakage, etc., so as to avoid the waste of space and increase the filling volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

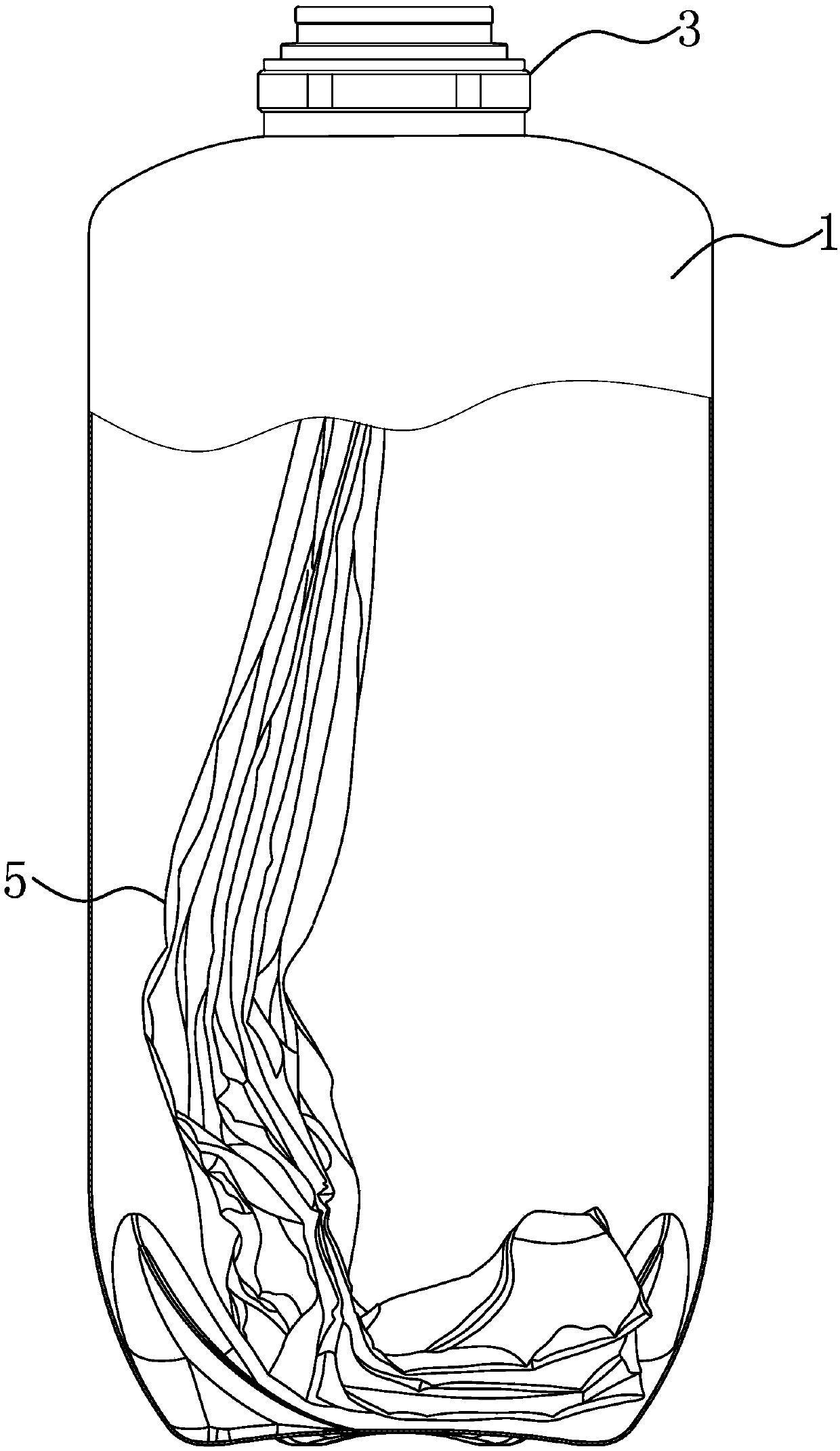

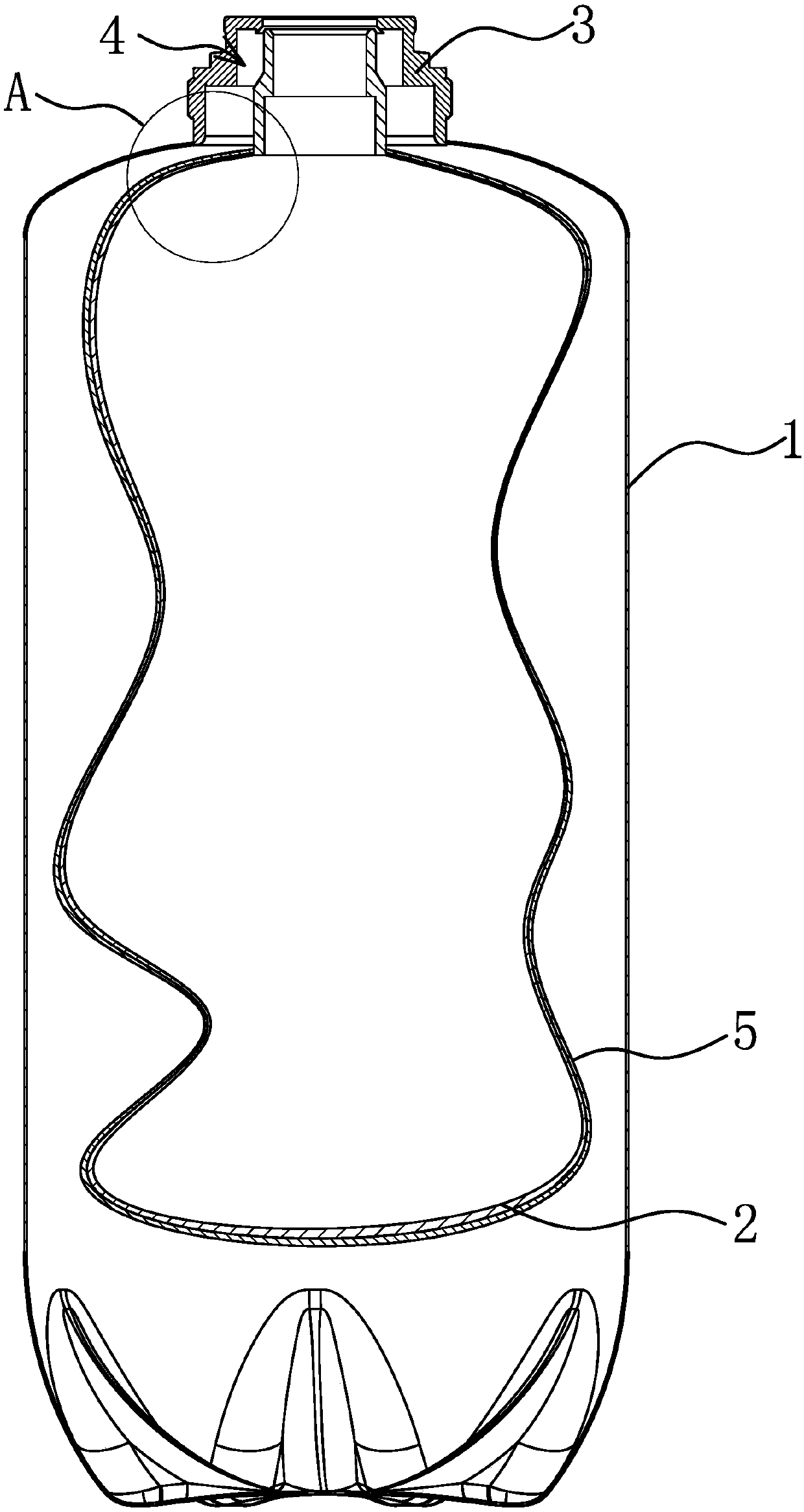

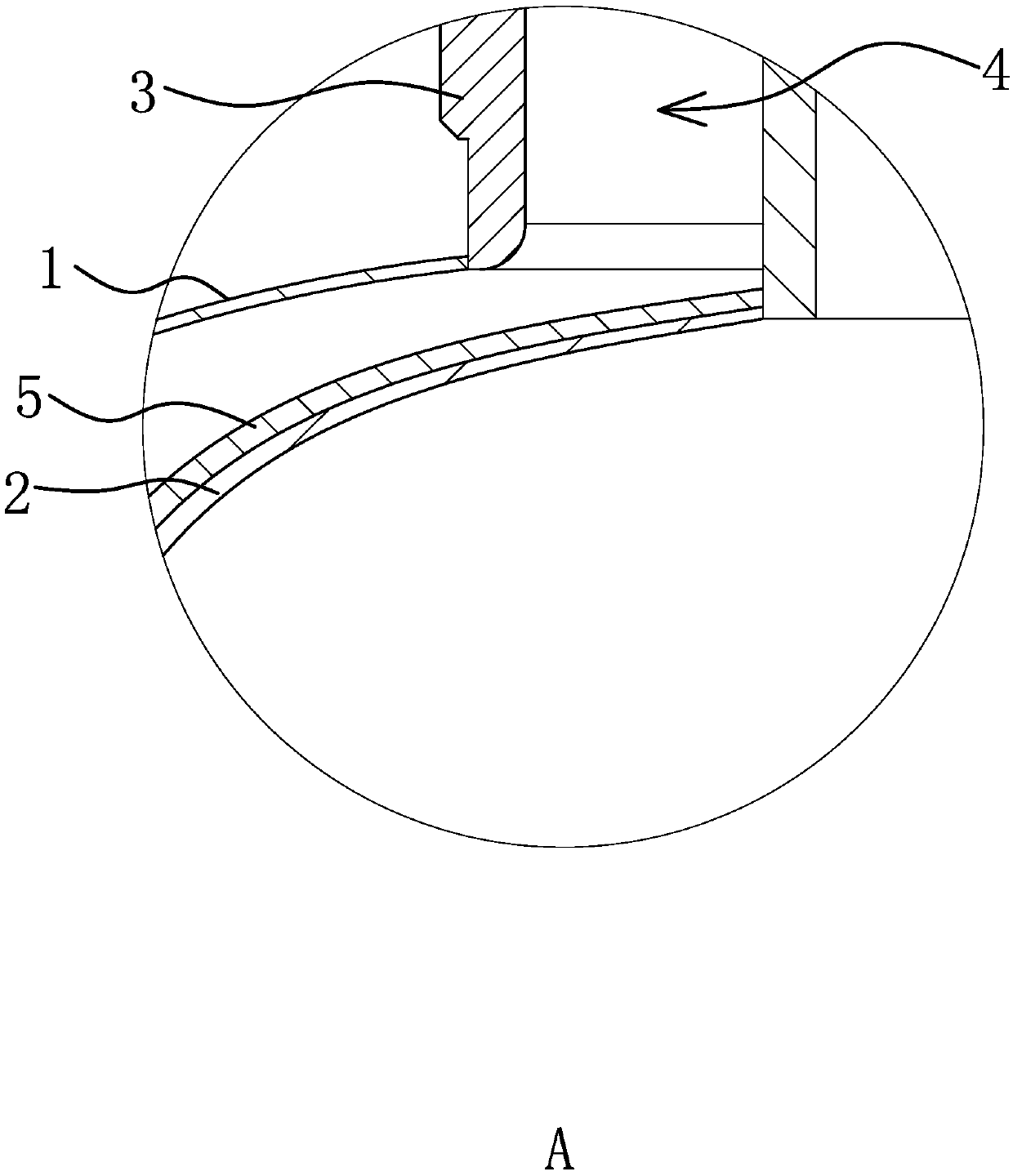

[0037] Such as Figure 1 to Figure 2 As shown, a liquid container includes a barrel-shaped outer shell 1, a flexible inner bag 2 arranged in the outer shell 1 for storing liquid, a liquid outlet valve 3 for controlling the liquid in and out of the inner bag 2, the inner bag 2 and the liquid outlet valve 3 is fixedly connected and the bag mouth of the inner bag 2 forms a seal with the liquid outlet valve 3, and the outer shell 1 forms a seal with the liquid outlet valve 3, and the end of the outer shell 1 connected with the liquid outlet valve 3 is also connected with a ventilator that can control the gas in and out of the outer shell 1 Structure 4, the ventilation structure 4 includes a ventilation channel 1 located on the liquid outlet valve 3 . Ventilation channel 1 can be directly provided on the liquid outlet valve 3, so that various liquid discharge structures and vent structures 4 are relatively compact.

[0038] Such as image 3 , Figure 4 As shown, a separation bag...

Embodiment 2

[0044] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 5 As shown, the shape of the protrusion 511 is a triangle, and the triangular protrusion 511 is also very convenient to process, easy to form, and the edges are relatively neat, which can ensure that the edges of the formed auxiliary air channel 1 52 and auxiliary air channel 2 512 are relatively smooth, ensuring The gas is discharged smoothly,

Embodiment 3

[0046] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 6 to Figure 8 As shown, the convex portion 51 includes elongated convex strips 513 , and at least one convex strip 513 extends from the opening of the partition bag 5 to the bottom of the partition bag 5 . The arrangement of the convex strips 513 can ensure that the formed auxiliary air channel-52 is smooth from the beginning to the end, and ensure the smooth discharge of gas, so as to increase the filling volume of the liquid container during filling. Moreover, the complete convex strip 513 is easy to process and convenient to form. Specifically, the protruding strips 513 are wrinkled and formed by bonding the inner surfaces of the separation bag 5, that is, the inner surfaces of the separation bag 5 are partially pasted to form a wrinkled protrusion 511, and the protrusions 511 can be multiple Continuous pleats are superimposed to further enh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap