Intelligent water content detecting device for wellhead

A water detection and intelligent technology, applied in wellbore/well components, earthwork drilling, etc., can solve the problems of large measurement error, inaccurate measurement results, and great influence of measurement results, avoiding scaling and waxing, Avoid sampling inaccurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

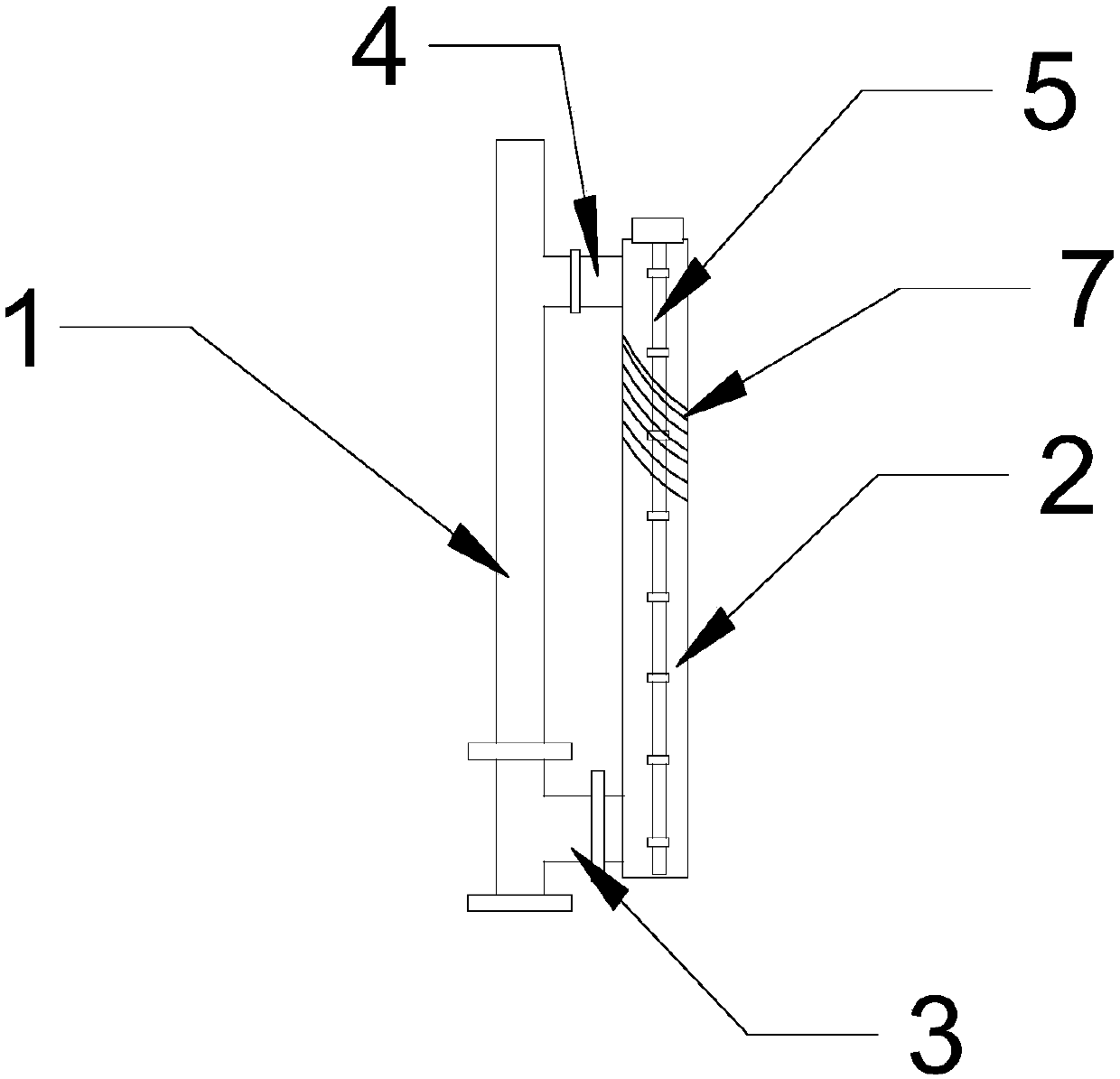

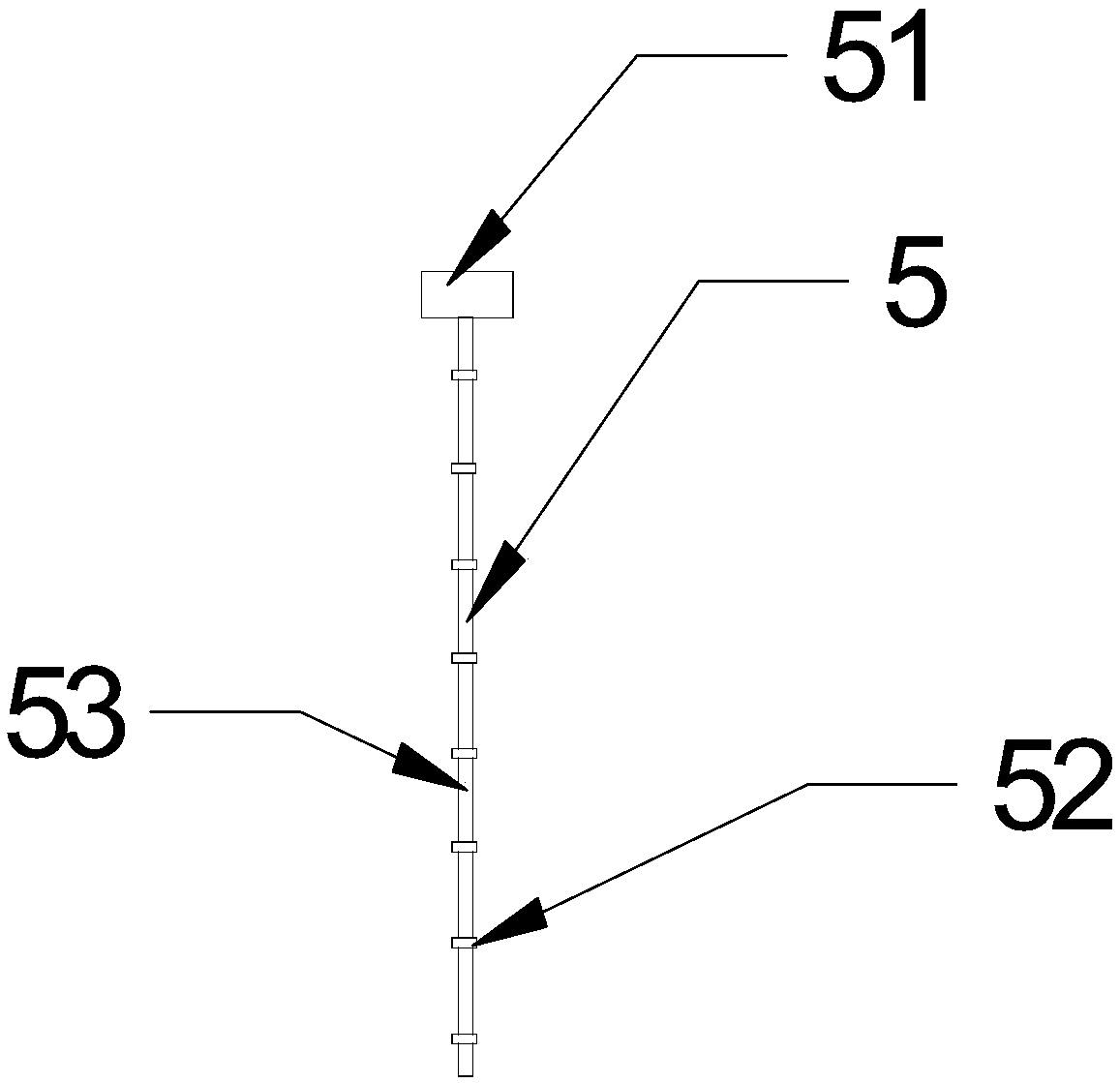

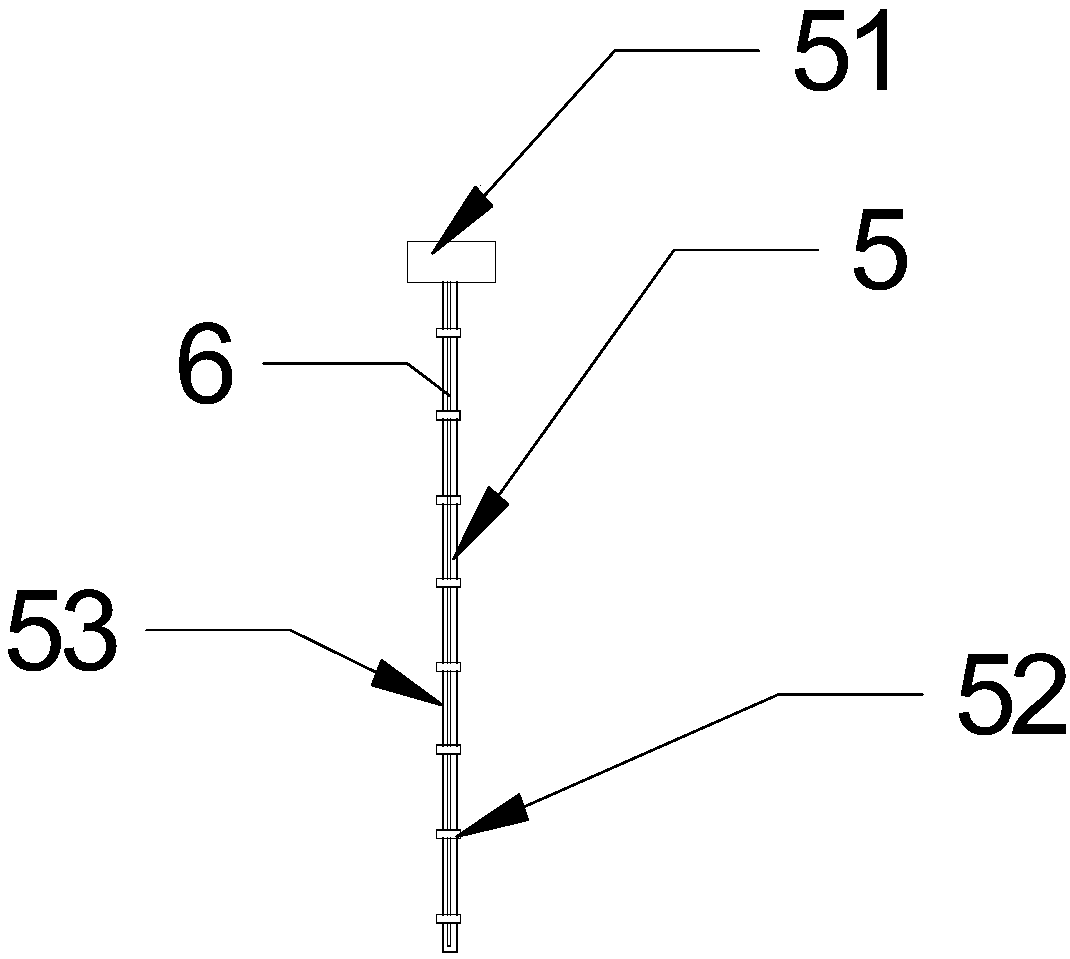

[0020] like figure 1 and figure 2 As shown, a wellhead intelligent water detection device of the present invention includes a production pipeline 1 and a metering pipeline 2 connected to the production pipeline 1, and the inlet end of the metering pipeline 2 passes through a three-way valve 3 communicates with the inlet of the production pipeline 1, and the outlet of the metering pipeline 2 communicates with the outlet of the production pipeline 1 through a valve 4; a heating device 7 is arranged on the outer wall of the metering pipeline 2, and the metering pipeline The inboard of 2 is equipped with the detector 5 that is distributed with a plurality of water oil sensors that extends from the upper end of the metering pipeline to the lower end. When sampling, the outlet of the production pipeline 1 will be closed, and the inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com