Blasting mining face after-blasting wind and water joint mist spraying automatic opening device and mounting method

An automatic opening and opening device technology, which is applied in safety devices, mining equipment, earthwork drilling, etc., can solve the problems of personal injury of construction workers, prolonging the time of watering and dust reduction, gas and coal dust explosion, etc., and achieves simple structure, Wide application range and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

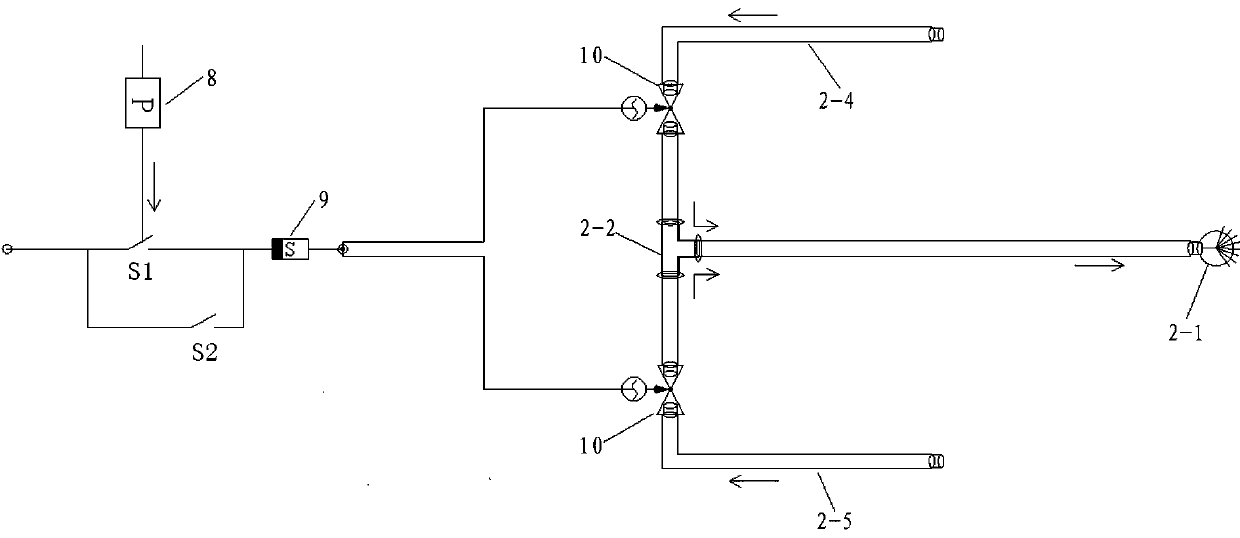

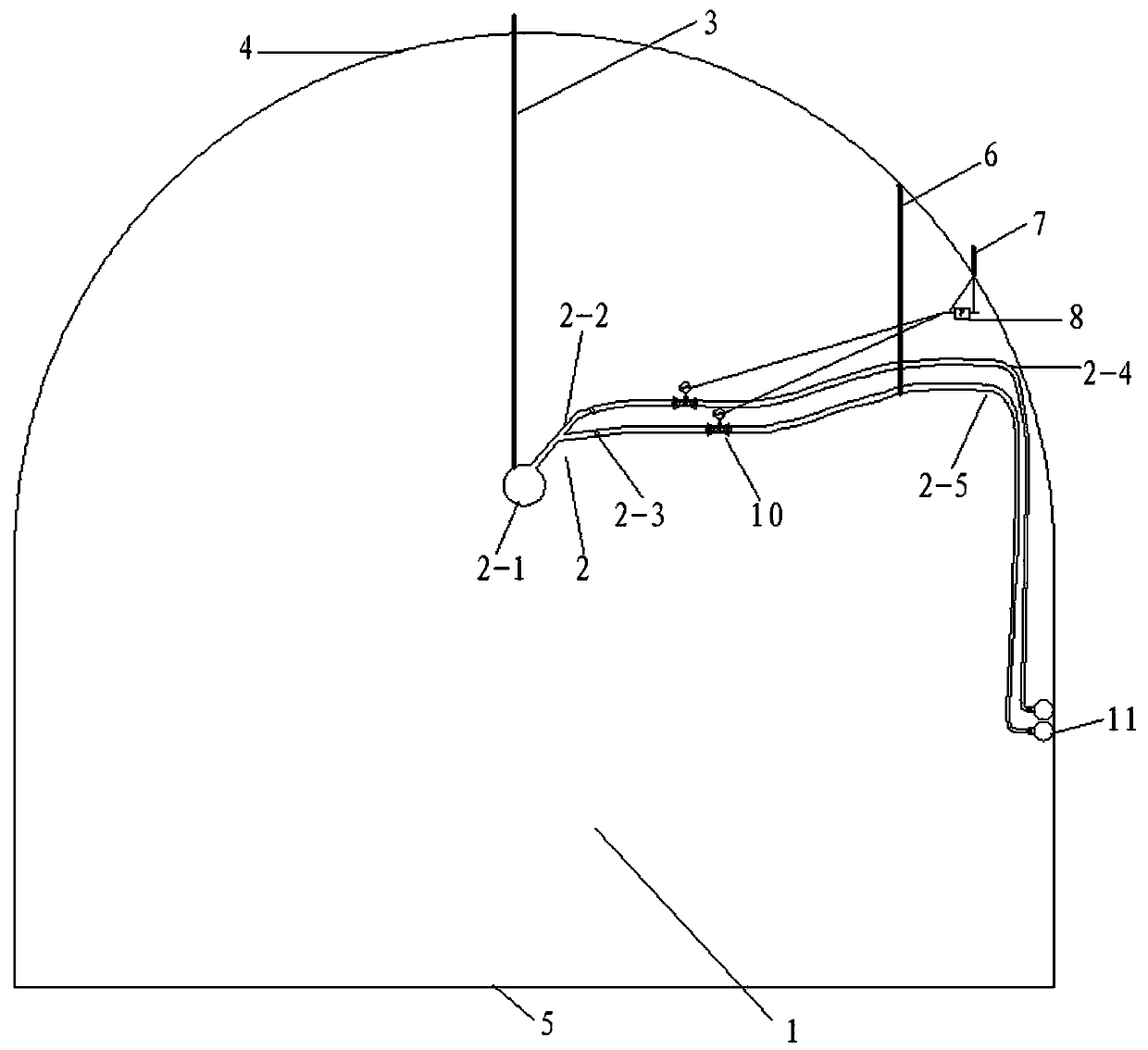

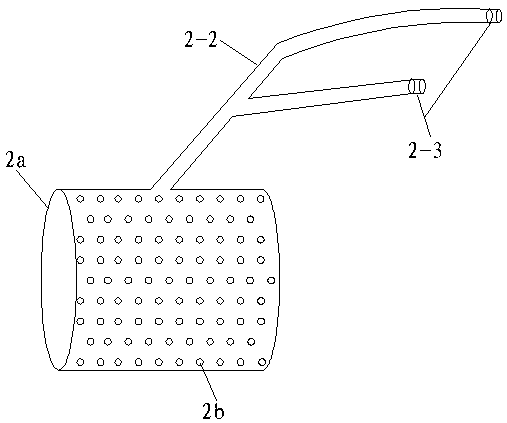

[0022] Such as figure 1 , figure 2 , image 3 Shown, a kind of wind and water combined spraying automatic opening device after blasting on the blasting mining face, the opening device includes a purification water curtain device 2 and a control circuit; the purification water curtain device 2 includes a nozzle 2-1, a wind and water pipe 2-2, Wind belt 2-4, water belt 2-5; Feng Shui pipe 2-2 is a T-type three-way valve, the main pipe of this T-type three-way valve is connected with the nozzle 2-1 through a pipeline, and the branch of this T-type three-way valve The fork pipe is connected with wind belt 2-4 and water belt 2-5 respectively. The nozzle 2-1 is connected with the wind belt 2-4 and the water belt 2-5 through the wind water pipe 2-2; the control circuit includes a pressure sensitive sensor 8 and a time relay 9; the normally ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com