Air intake equipment of gas-fired boiler

A gas-fired boiler and air-intake technology, which is applied in the field of gas-fired boilers, can solve problems such as unstable electrical equipment signals, reduced equipment operating efficiency, and increased maintenance costs, and achieves optimized air inlet pipe structure, high blast efficiency, and easy operation and maintenance. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

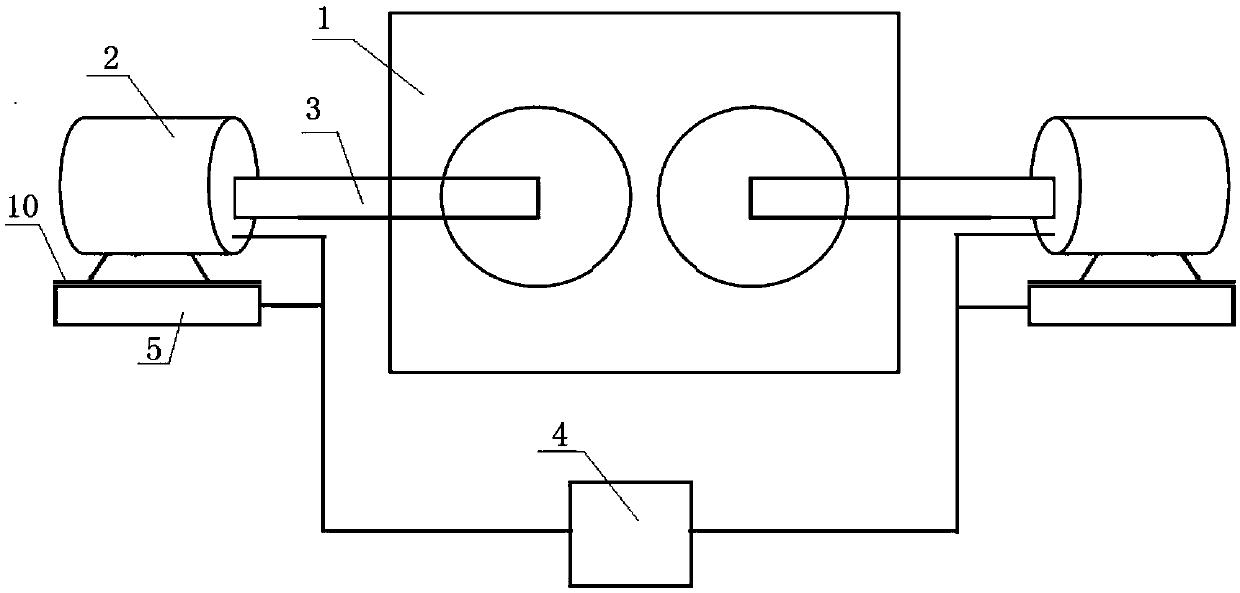

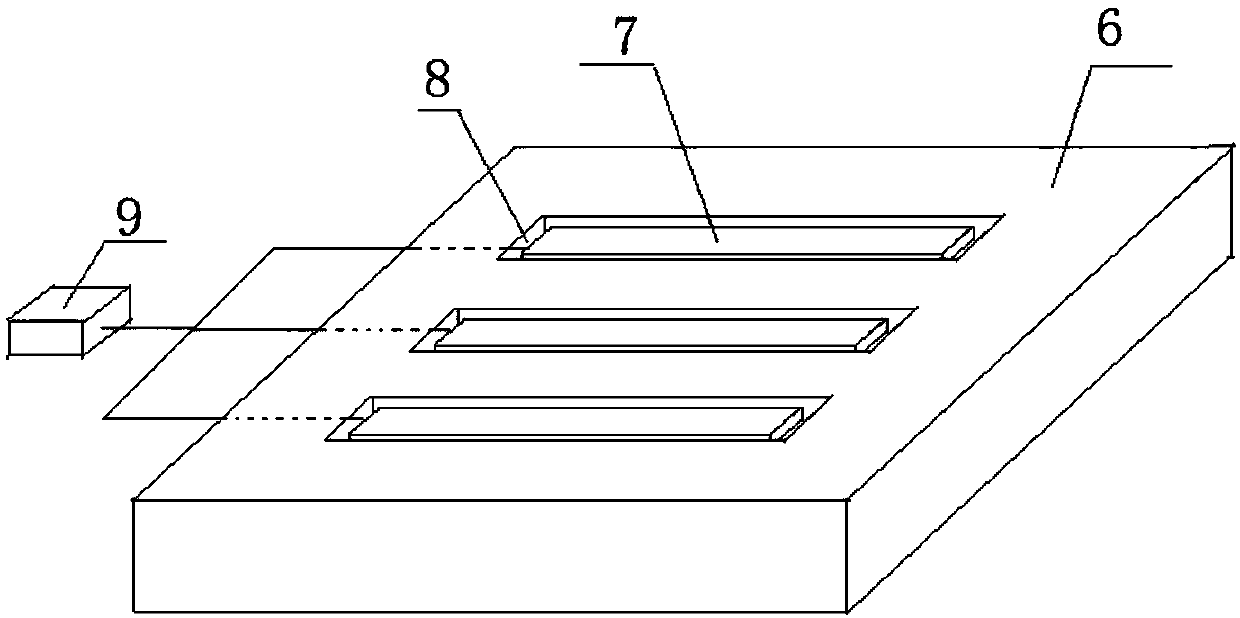

[0023] A gas-fired boiler air intake device, such as figure 1 As shown, it is used for a gas boiler 1, including a controller 4, a temperature sensor connected to the controller 4 and two frequency conversion fans 2 of the same type, and the two frequency conversion fans 2 are symmetrically arranged on the ground on both sides of the gas boiler 1 , are respectively connected to the combustion chamber of the gas boiler 1 through the air supply pipe 3. In this embodiment, the frequency conversion fan 2 is a three-phase AC frequency conversion fan, and the air supply pipe 3 is L-shaped, with an elbow at the bend. The temperature sensor is set in the combustion chamber of the gas boiler 1 , and the controller 4 receives the signal from the temperature sensor and synchronously adjusts the air volume of the two frequency conversion fans 2 to blow air for the gas boiler 1 together.

[0024] In this embodiment, a magneto-rheological shock absorber 5 is provided between the variable fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com