busbar clamp

A technology of busbars and sub-busbars, applied in the field of busbar clamping, can solve the problems of reducing the carrying capacity of busbars, clamping busbars at the same time, and interference from surrounding personnel, so as to reduce vibration, improve versatility, and reduce vibration noise pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

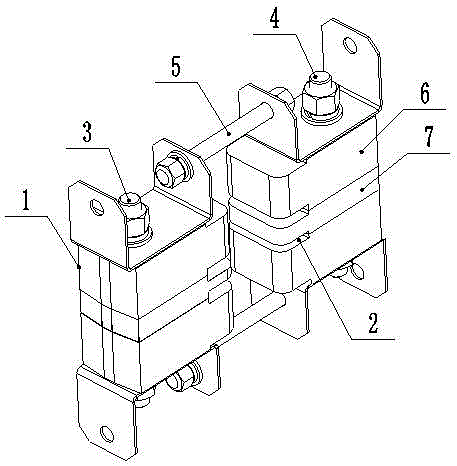

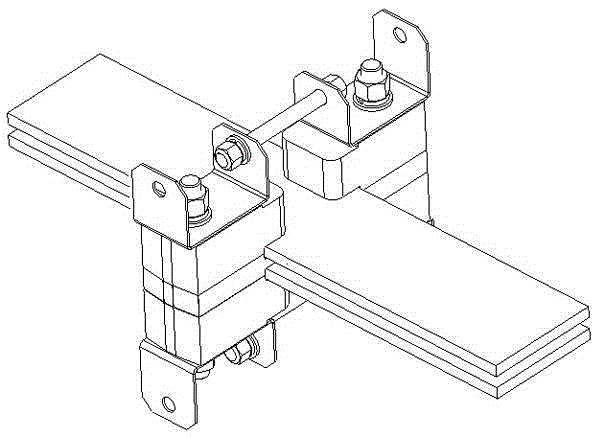

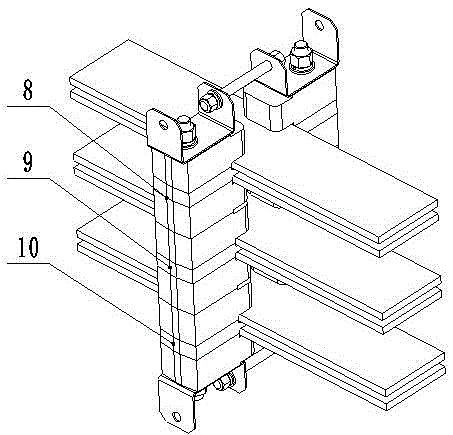

[0040] Such as Figure 3~5 Shown, present embodiment one by structure such as figure 2 The shown first unit busbar clamp 8, second unit busbar clamp 9 and third unit busbar clamp 10 are combined, the first unit busbar clamp 8, the second unit busbar clamp 9 and the third unit busbar clamp The clamps 10 are arranged next to each other from top to bottom. The above three unit busbar clamps share the same first stud 3, second stud 4 and corresponding nuts, and are located below the first unit busbar clamp 8. The gold fittings, the fittings above and below the busbar clamp 9 of the second unit, and the fittings above the busbar clamp of the third unit are removed, leaving only the fittings 8 above the busbar clamp of the first unit and the busbar of the third unit The hardware below the clamp 10 clamps each unit busbar clamp.

Embodiment 2

[0042] Such as Figure 6~9 As shown, the second embodiment consists of a structure such as figure 2 The fourth unit bus bar clamp 11, the fifth unit bus bar clamp 12 and the sixth unit bus bar clamp 13 are combined, the fourth unit bus bar clamp 11, the fifth unit bus bar clamp 12 and the sixth unit bus bar clamp The row clamps 13 are arranged next to each other in the horizontal direction, and the adjacent sub-mother-bar clamps 1 share a piece of hardware above and below them, and the fourth unit bus-bar clamp 11 and the fifth unit are connected by the shared hardware. The unit busbar clamp 12 and the sixth unit busbar clamp 13 are fixedly connected in sequence.

Embodiment 3

[0044] Such as Figure 10~13 Shown, present embodiment three by structure such as figure 2 The seventh unit busbar clamp 14, the eighth unit busbar clamp 15 and the ninth unit busbar clamp 16 are combined, and the arrangement of the seventh unit busbar clamp 14 and the eighth unit busbar clamp 15 is the same as the implementation In Example 1, the first unit busbar clip 8 and the second unit busbar clip 9 are arranged in a similar manner, while the arrangement of the eighth unit busbar clip 15 and the ninth unit busbar clip 16 is similar to that of the fourth unit in Example 2 The busbar clips 11 and the fifth unit busbar clips 12 are arranged in a similar manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com