Rail vibration absorbing device for rail transit

A rail transit and rail technology, applied in the field of rail transit, can solve problems such as driving safety hazards, aggravated vehicle vibration, and potential safety hazards, and achieve the effects of reducing maintenance costs, reducing vibration and noise pollution, and improving driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in conjunction with accompanying drawing and specific embodiment:

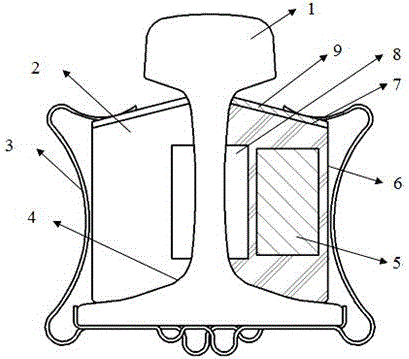

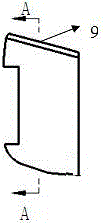

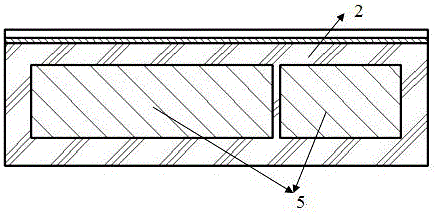

[0032] Such as figure 1 As shown, a rail vibration-absorbing device for rail transit, the rail vibration-absorbing device includes an elastic body 2, a mass 5 and an elastic fixing clip 3; the elastic body 2 is arranged on both sides of each steel rail 1 and Arranged along the longitudinal direction of the rail 1, the outline of the contact surface 4 between the elastic body and the rail is consistent with the outer surface of the rail 1; fit tightly figure 2 , image 3 , the mass block 5 is embedded in the elastic body 2 and arranged along the longitudinal direction of the elastic body 2; there is a cavity between the mass block 5 and the rail waist of the rail 1. In this embodiment, the The above-mentioned cavity is formed between the groove I8 arranged along the rail laying direction on the joint surface of the elastic body and the rail waist and the rail waist,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com