Full-automatic sweet potato bean sheet jelly maker

A sweet potato flour, fully automatic technology, applied in the field of fully automatic chemical sweet potato flour skin device, can solve the problems of increased production cost, low production efficiency, large labor cost, etc., and achieves the effect of improving production efficiency, reducing production cost and realizing automatic cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

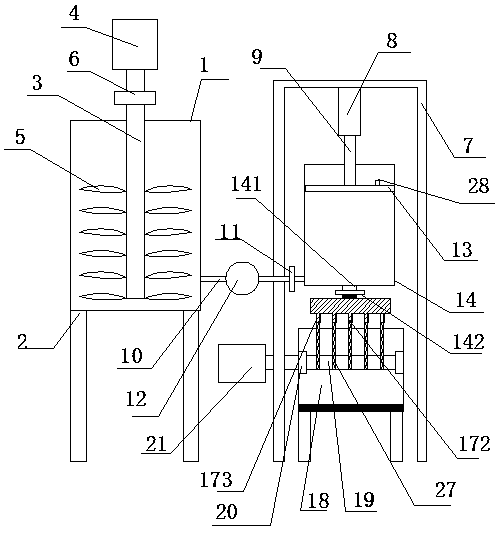

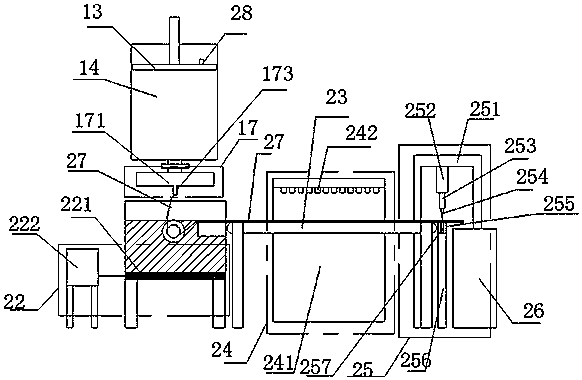

[0018] Such as Figure 1-2 Shown, a kind of full-automatic sweet potato vermicelli device of chemical industry, comprises mixing barrel 1, installation frame one 2, transmission shaft 3, motor one 4, stirring blade 5, speed reducer 6, installation frame two 7, hydraulic cylinder 8, hydraulic rod 9 , connecting pipe 10, solenoid valve one 11, material pump 12, pressure plate 13, pressure barrel 14, extrusion box 17, cooling box 18, transmission roller 19, installation shaft 20, motor two 21, condensation device 22, conveyor belt 23 , drying device 24, shearing device 25, collection bucket 26, powder skin 27, it is characterized in that: described mixing bucket 1 is installed on the installation frame 2, and described transmission shaft 3 is installed in the mixing bucket 1, described The stirring blade 5 is installed on the transmission shaft 3, the speed reducer 6 is connected with the transmission shaft 3, the motor one 4 is connected with the speed reducer 6, and the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com