Nail making combined die for hobnail core of blind rivet

A technology of blind rivets and flat-head nails, which is applied in the direction of nails, connecting components, pins, etc., and can solve problems such as nail tip flashes and burrs that are easy to fall off, affect the normal operation of electrical appliances, and safety accidents, and achieve good environmental protection effects and reduce molds Loss, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

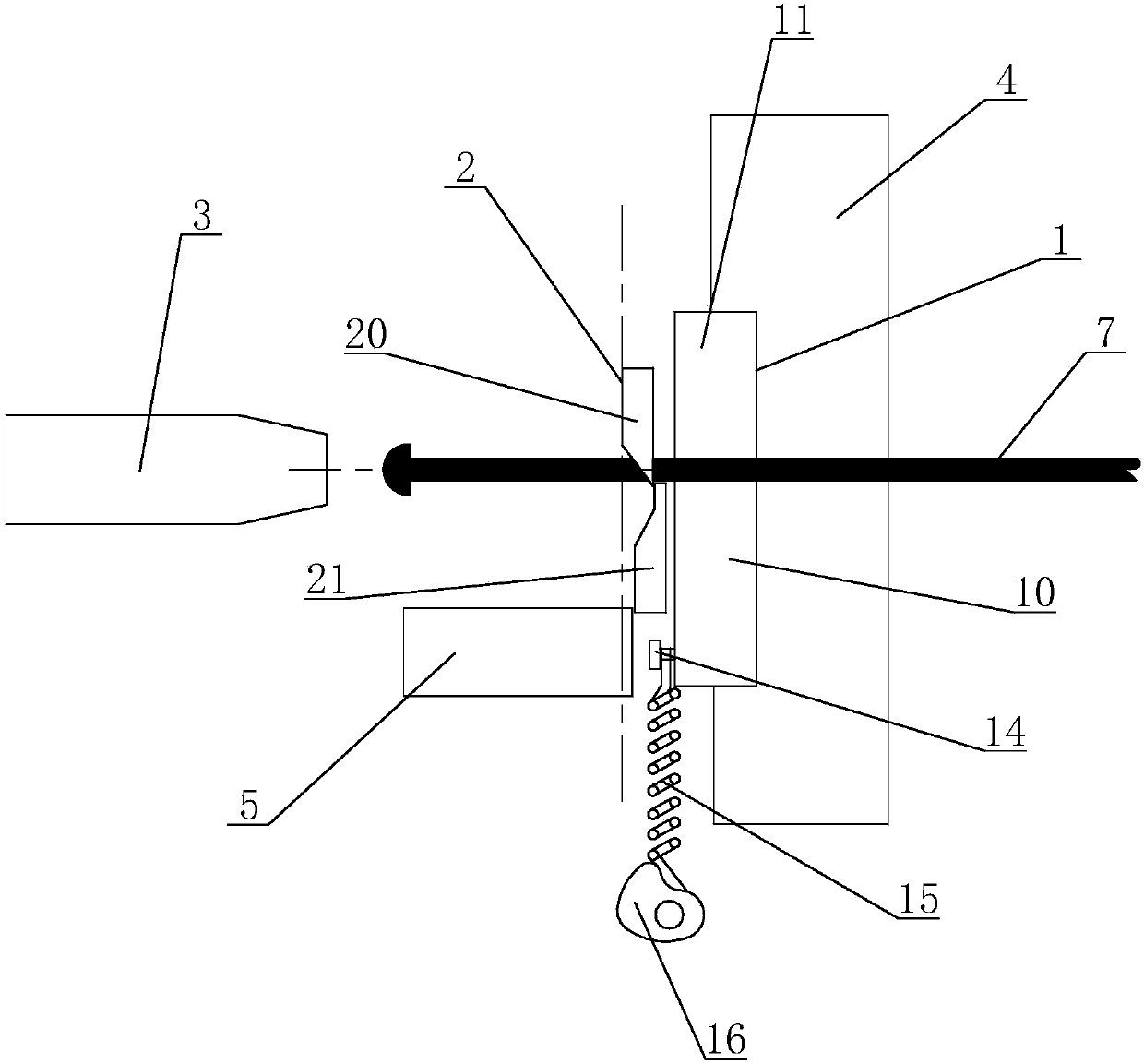

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

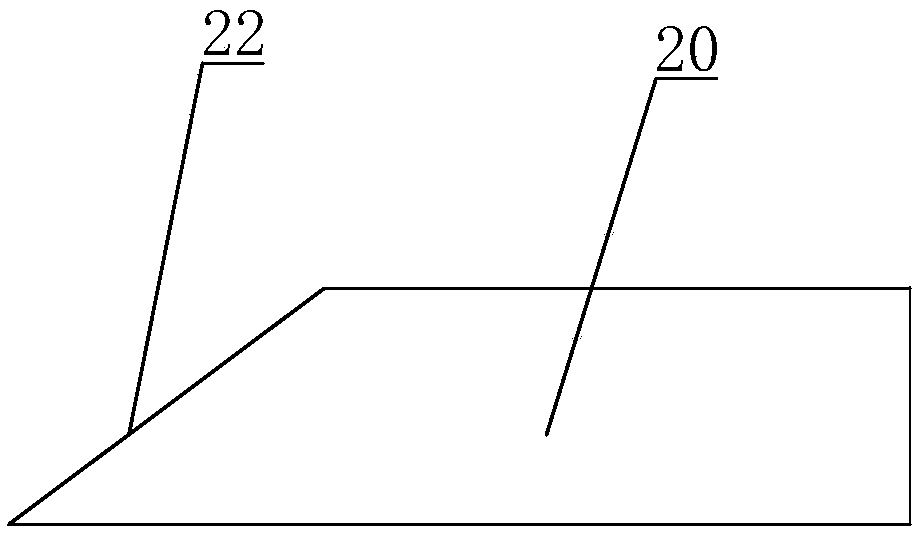

[0021] see Figure 1 to Figure 5 As shown, in the present embodiment, a blind rivet flat-head nail core nail making combination mold includes a main mold 1, a shearing tool 2 and a punch 3, and the main mold 1 is installed in the main mold box 4, and the punch The head 3 is arranged on one side of the main mold 1 , the shearing tool 2 is arranged between the punch 3 and the main mold 1 , and a staple box 5 is arranged below the shearing tool 2 .

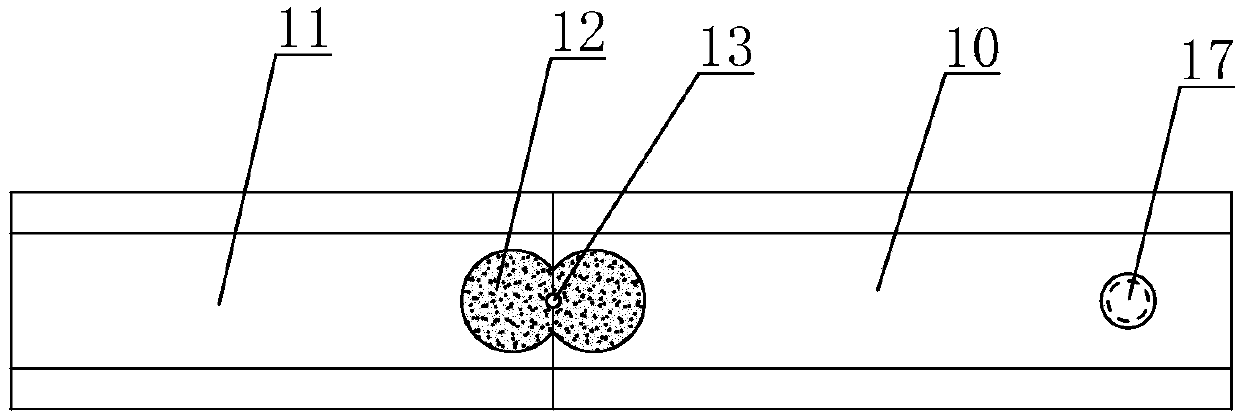

[0022] The main mold 1 includes a movable mold 10, a static mold 11 and a main mold drive, and the movable mold 10 and the static mold 11 are correspondingly provided with semicircular mold cavities, and the main mold drive connects the movable mold and drives the movable mold Open and close the mold with the static mold. After the movable mold 10 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com