Hydraulic fixing type belt putting fixing device

A fixed and fixer technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the belt cannot be lowered smoothly, the running belt can not effectively control the speed of the belt, and achieve effective control of the release. Bring speed, eliminate safety hazards, and be easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

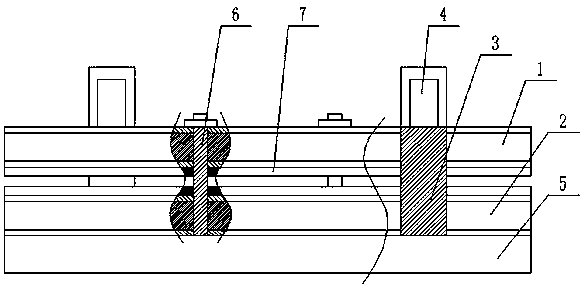

[0013] Such as figure 1 As shown, the hydraulically fixed belt belt fixing device of the present invention includes an upper I-beam 1, a lower I-beam 2, a jack fixing frame 3 and a jack 4, and the lower I-beam 2 is horizontally fixed on the conveyor belt frame 5, the upper I-beam 1 is located directly above the lower I-beam 2, and the upper I-beam 1 and the lower I-beam 2 are connected in series through a guide column 6, and the guide column 6 Through the longitudinal beams of the upper I-beam 1 and the lower I-beam 2, the lower end of the jack holder 3 is fixed on the conveyor belt frame 5, and the jack holder 3 is located between the upper I-beam 1 and the lower I-beam. On the outer side of the beam 2, the upper end of the jack holder 3 is provided with a jack 4, the jack 4 is vertically arranged, and the cylinder body of the jack 4 is fixedly arranged on the jack holder 3, and the piston rod of the jack 4 Connected to the upper I-beam 1, the gap between the upper I-beam 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com