Novel charging table and discharging table equipment

A material table and a new type of technology, applied in metal processing and other directions, can solve the problems of low cutting precision, few types of steel, and high equipment cost, and achieve the effect of high cutting precision, low equipment cost and high conveying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

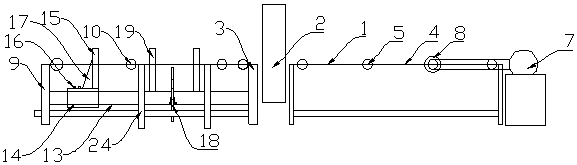

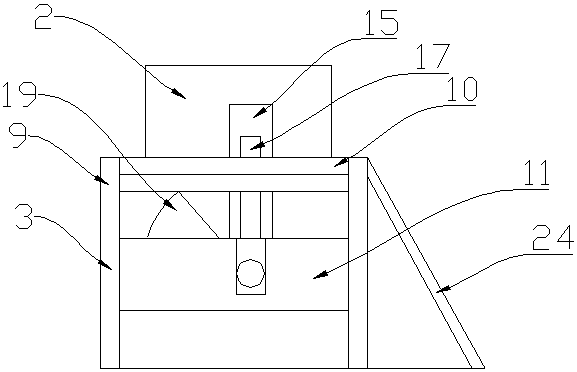

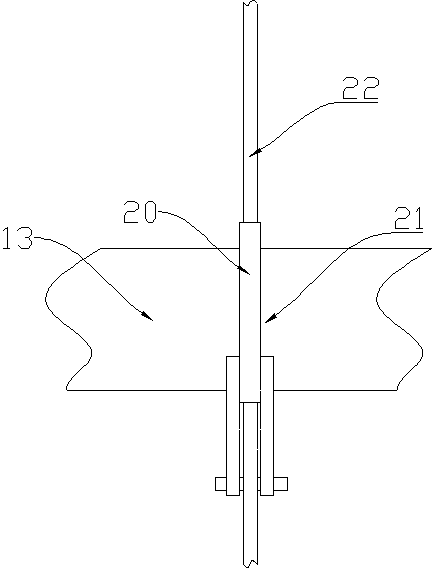

[0023] Example: such as Figure 1-5As shown, a new type of loading table and unloading table equipment, including loading table device 1, cutting device and unloading table device 3, loading table device 1 is located on the right side of cutting device 2 and has a distance from cutting device 2 , the lower part of the loading table device 1 is provided with a loading table support 4, and a plurality of feeding rollers 5 are arranged on the upper surface of the feeding table support 4 along the front and rear direction, and the front and rear ends of the feeding roller 5 are connected to the upper surface of the feeding table support 4 respectively. The front end and the rear end of the front end are rotationally connected, and the front end of the feeding drum 5 located at the rightmost end on the loading platform support 4 is fixedly provided with a rotating wheel 6, which is coaxially arranged with the feeding drum 5 and the outer diameter of the rotating wheel 6 is larger th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com