Track roller blind dust shield and track with same

A roller shutter and track technology, applied in the manufacture of tools, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of scratching the track, affecting the service life of the track, and being easy to scatter, so as to ensure smooth progress and prolong service life. , The effect of reducing track wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further described in conjunction with the following examples.

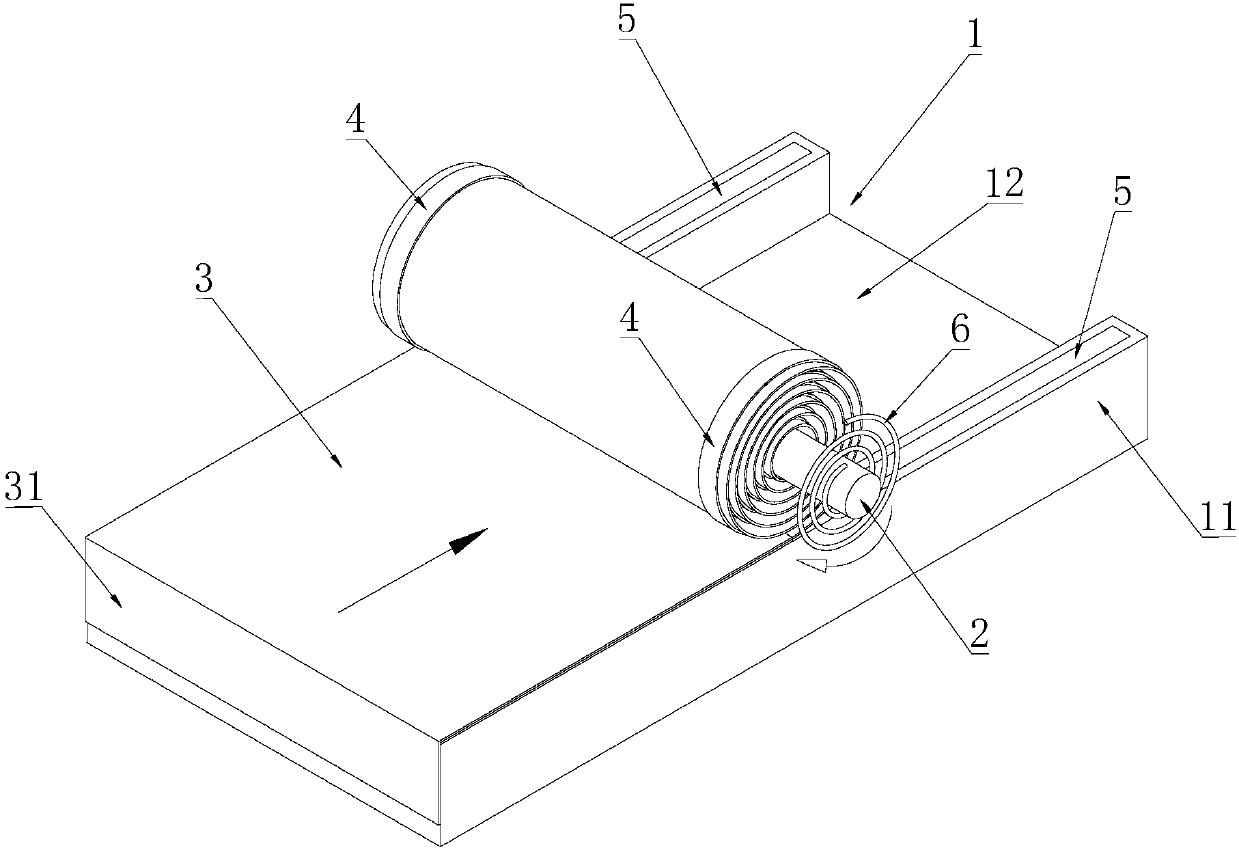

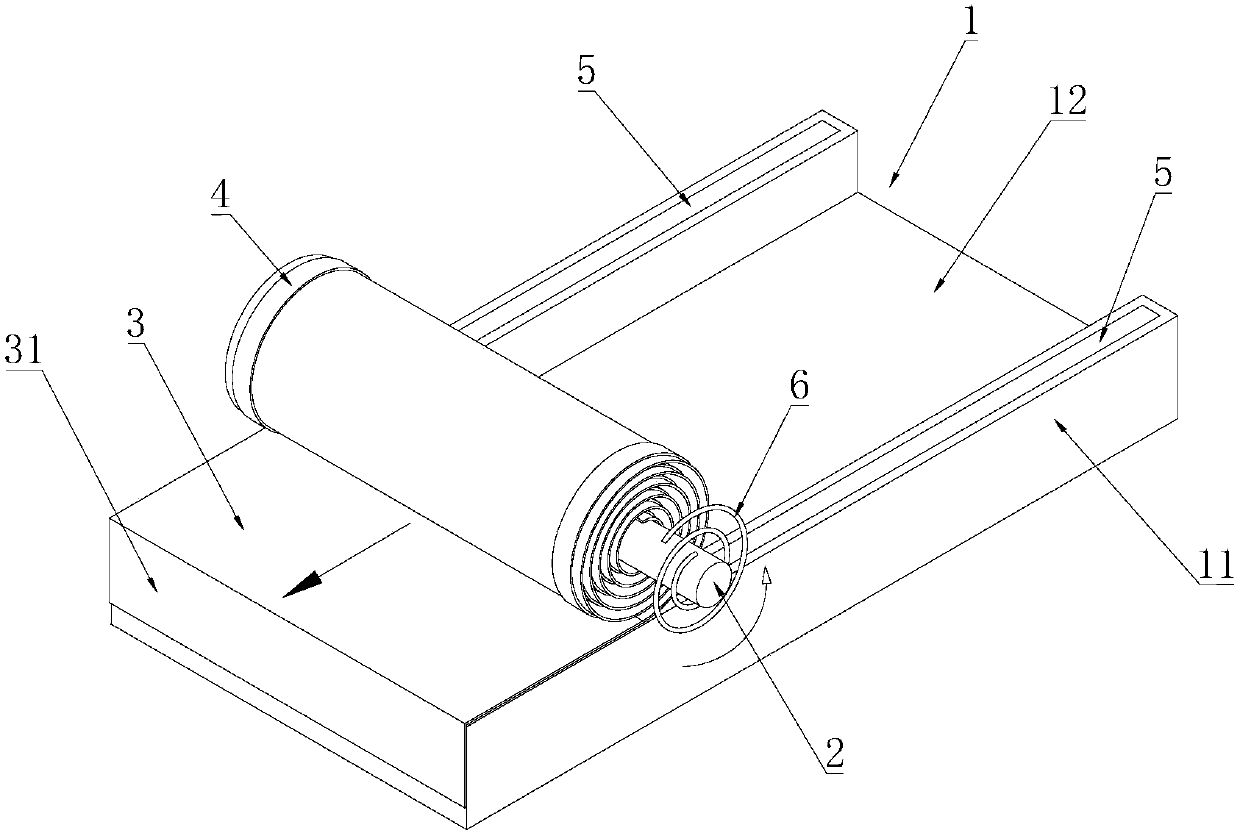

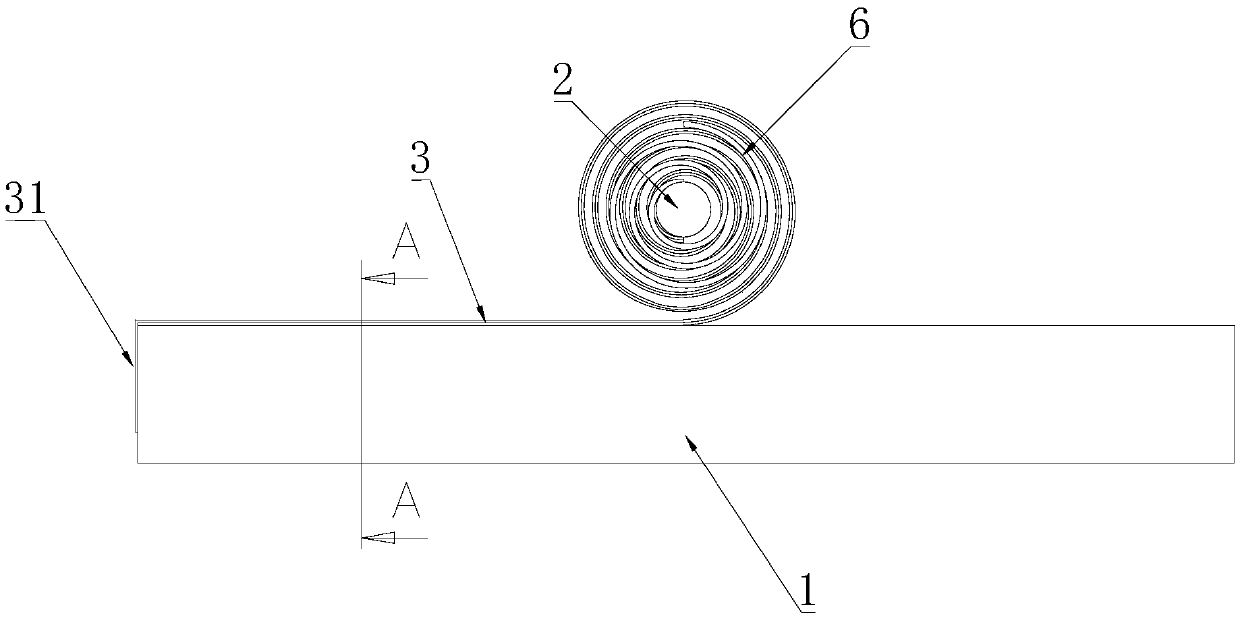

[0035] A kind of track roller shutter dustproof cover of the present invention, as figure 1 and figure 2 As shown, its structure includes a roller blind 3 and a reel 2. The left end of the roller blind 3 is fixed on the left end of the track 1. Specifically, the left end of the roller blind 3 is bent with a 90-degree hem portion 31, and the hem portion 31 is just It is clamped on the left end surface of the track 1, and the hem portion 31 is fixedly connected to the left end surface of the track 1, thereby fixing the left end of the roller blind 3 firmly. The right end of the roller blind 3 is fixed on the reel 2, the reel 2 can rotate, and the reel 2 is synchronized with the sliding plate sliding in the track 1 and moves horizontally in the same direction, so that with the rotation and movement of the reel 2, the roller blind 3 can be gradually rolled up On reel 2 to uncover tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com