Method and system for automatic robot teaching using vision and laser range finder

A technology of laser range finder and robot, which is applied in manipulators, program-controlled manipulators, manufacturing tools, etc. It can solve the problems of life safety impact on operators, inability to achieve a high degree of consistency, high skill requirements, etc., to achieve good consistency, The effect of reducing labor cost input and high teaching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

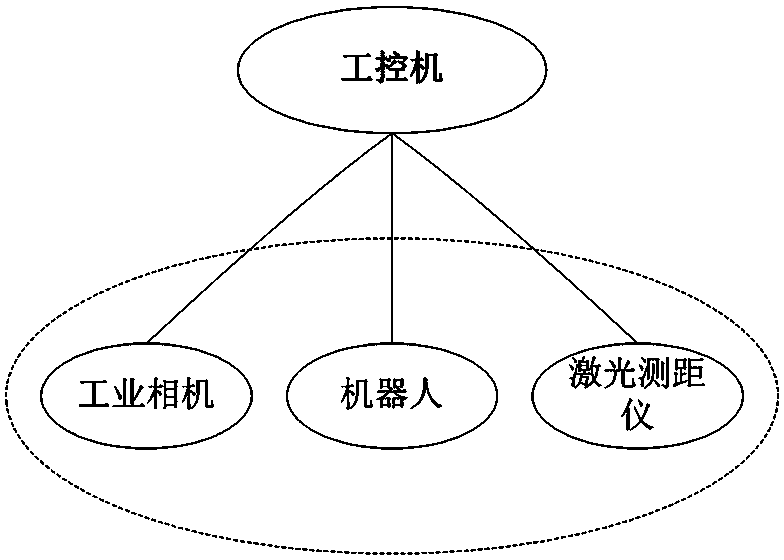

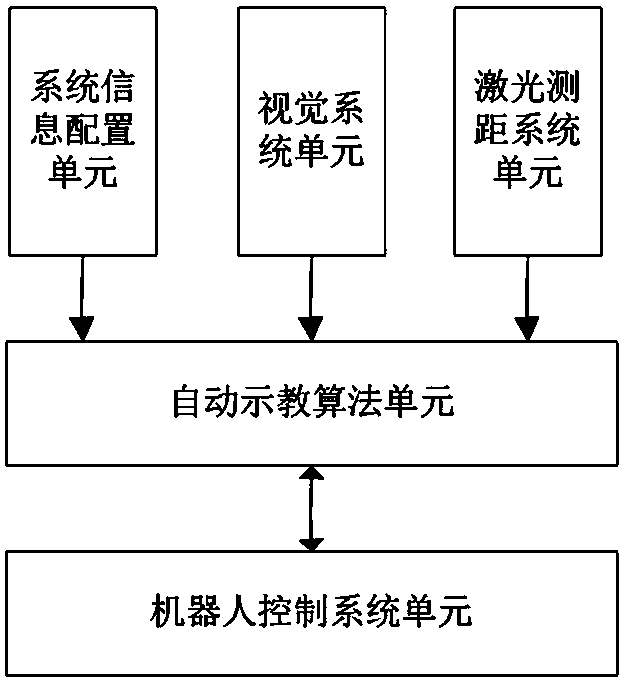

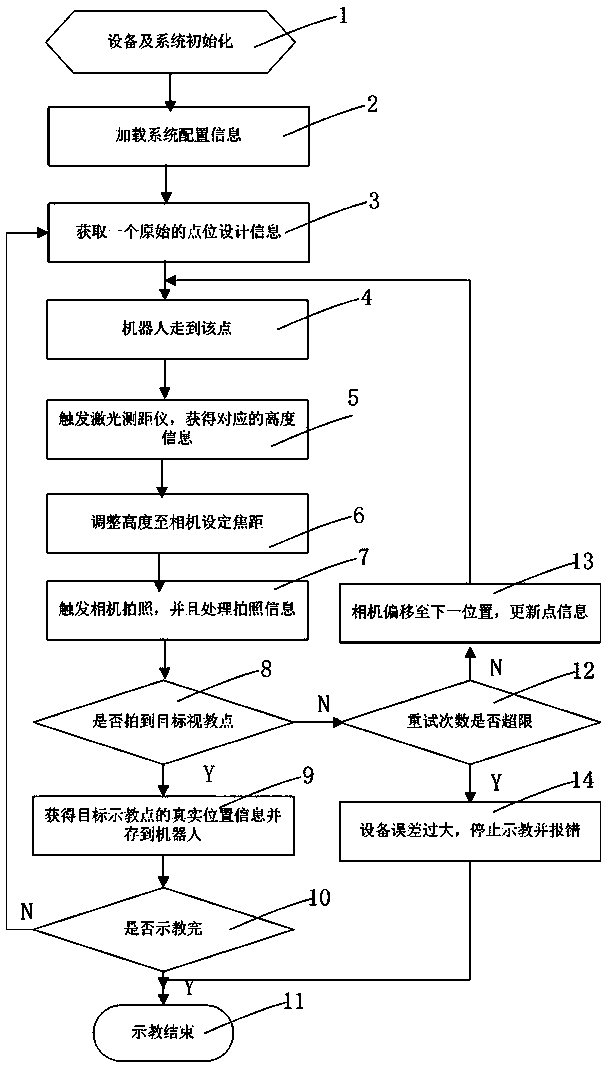

[0019] The invention provides a method and device for realizing automatic teaching based on the original point design information of the target teaching point provided by the mechanism designer, using an industrial camera and a laser range finder in cooperation with a robot. Due to factors such as assembly and processing, there is often a certain error between the actual position information of the target teaching point and the original point design information (such as original coordinates, angles, etc.). The present invention can automatically identify the actual position information of the target teaching point according to the original point design information, and then update the movement path of the robot, and perform fast automatic teaching on multiple target points, and at the same time, the error is too large to pass Teaching unqualified equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com