Ball screw type self-energized semi-active suspension actuator and control method thereof

A semi-active suspension, ball screw type technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve the problems of low energy feeding efficiency of the system, inability to adjust parameters for different models, shortening the service life of generators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

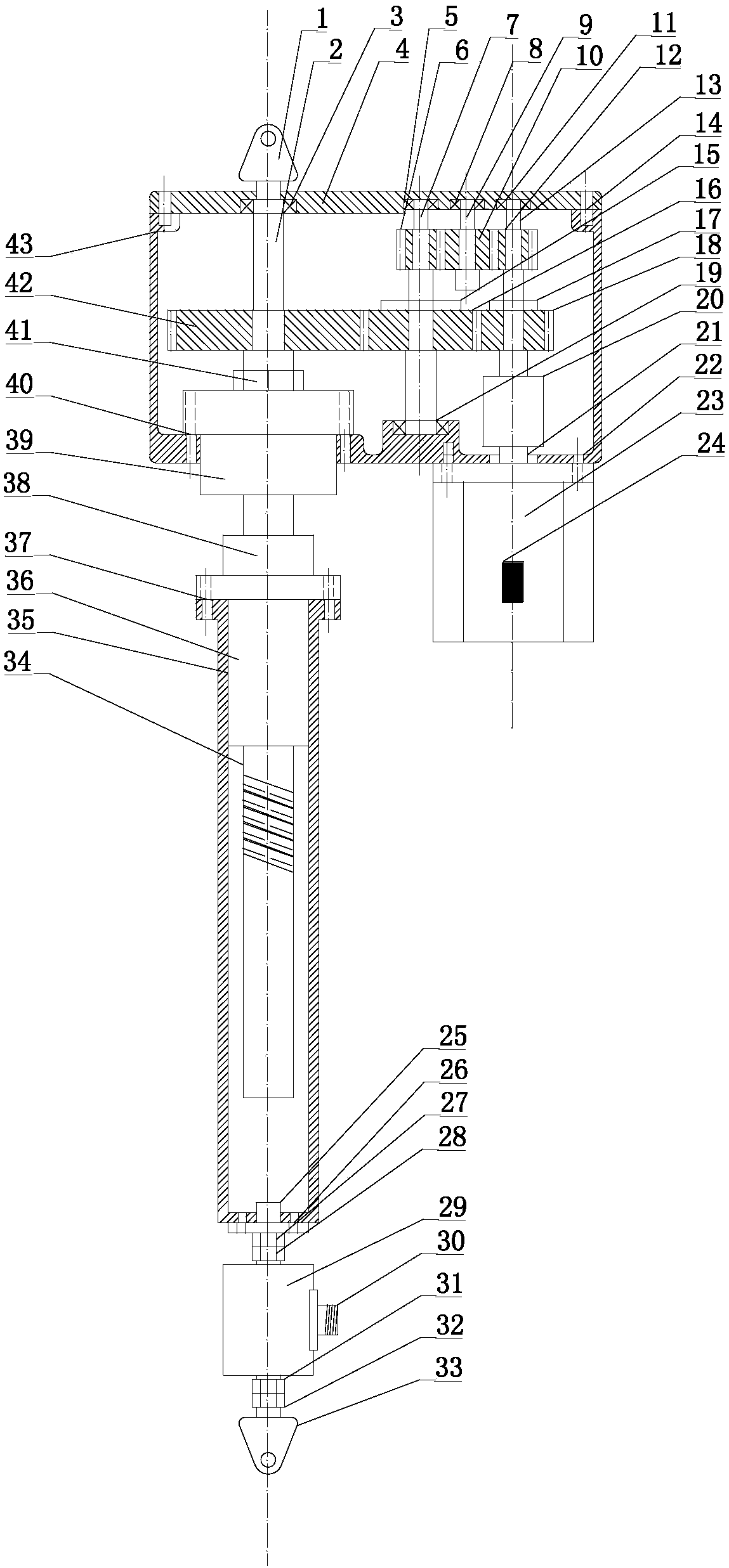

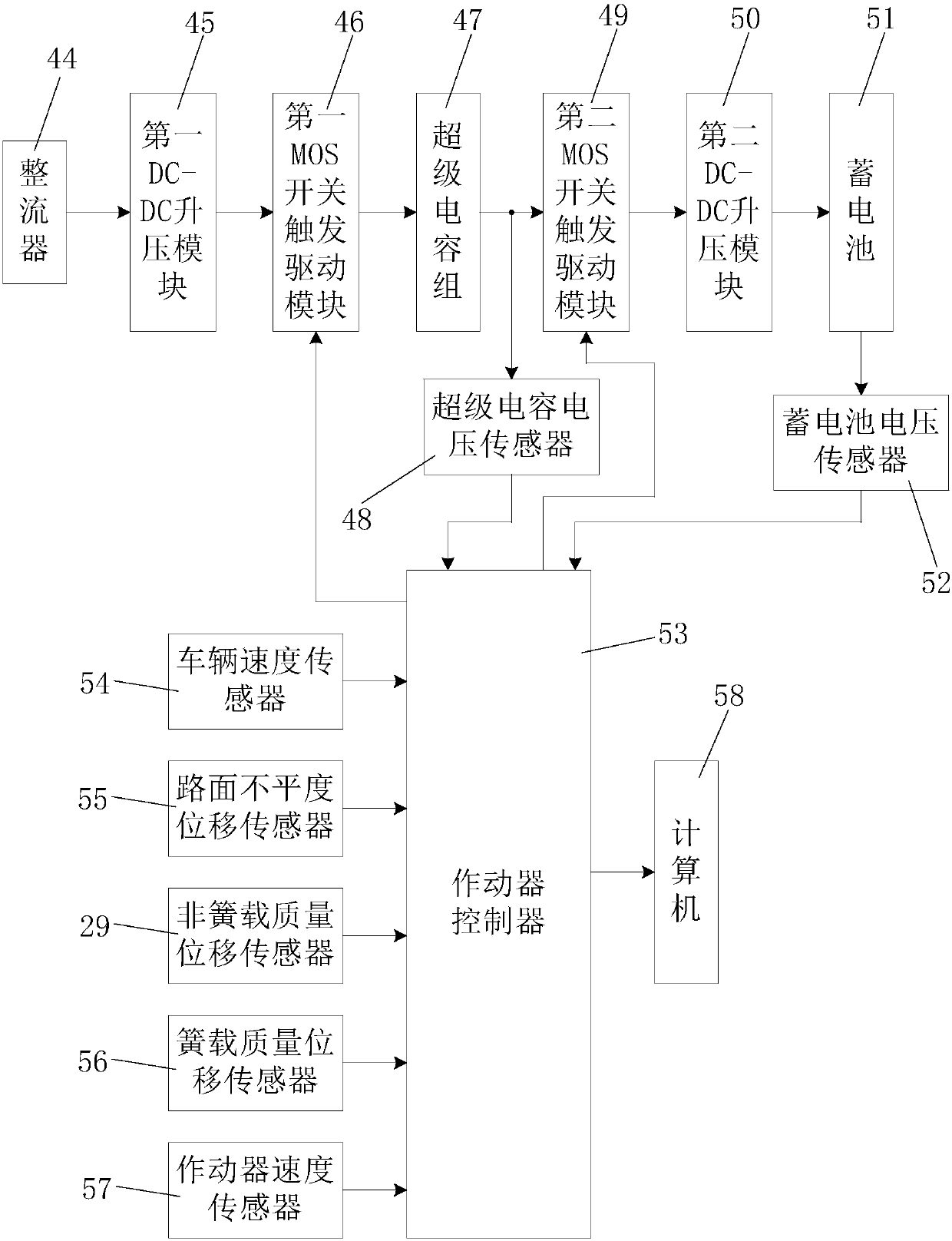

[0111] The ball screw type self-powered semi-active suspension actuator of the present invention includes an actuator body and an actuator control system, such as figure 1 As shown, the actuator body includes an upper housing 43 and a lower housing 35, and the upper housing 43 is provided with a screw shaft 2, a first transmission shaft 7, a second transmission shaft 9 and an output shaft 13, The top of the upper housing 43 is provided with an upper housing cover 4, and the upper housing cover 4 is embedded with a screw shaft bearing 3 for supporting and installing the screw shaft 2, and for supporting and installing the first transmission shaft 7. The first transmission shaft upper end bearing 5, the second transmission shaft bearing 8 for supporting and installing the second transmission shaft 9, and the output shaft bearing 11 for supporting and installing the output shaft 13, the bottom of the upper housing 43 is embedded with The fixed support seat 39 located below the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com