Long-arm robot

A robot and long-arm technology, applied in the field of long-arm robots, can solve problems such as dumping, surface damage of goods, unfavorable development of automation, etc., achieve reliable transmission process, realize the effect of changeable fixture position and loading method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

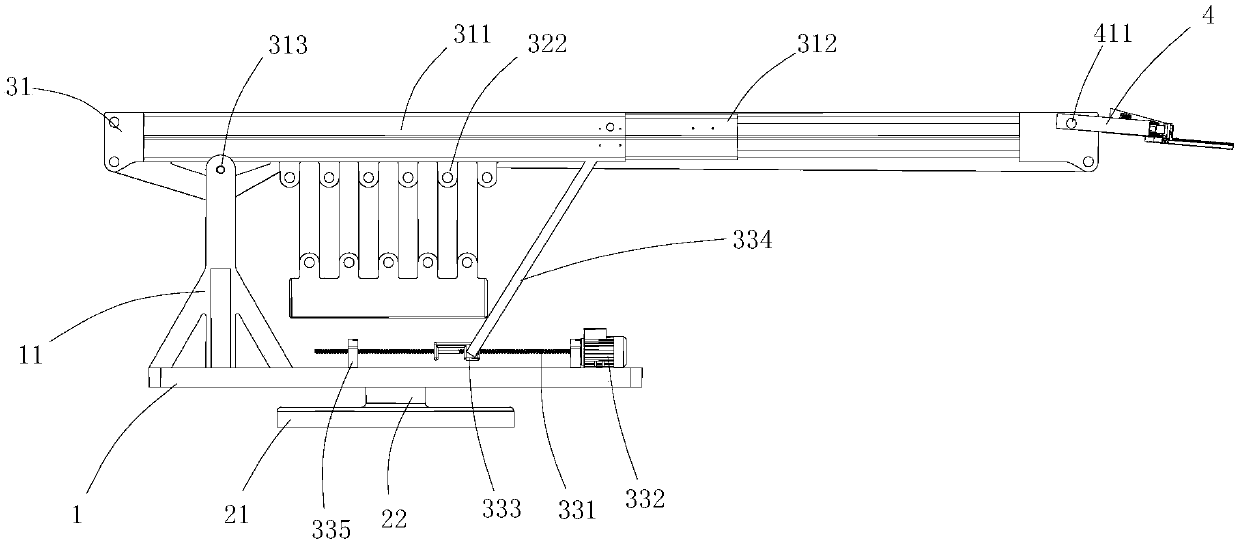

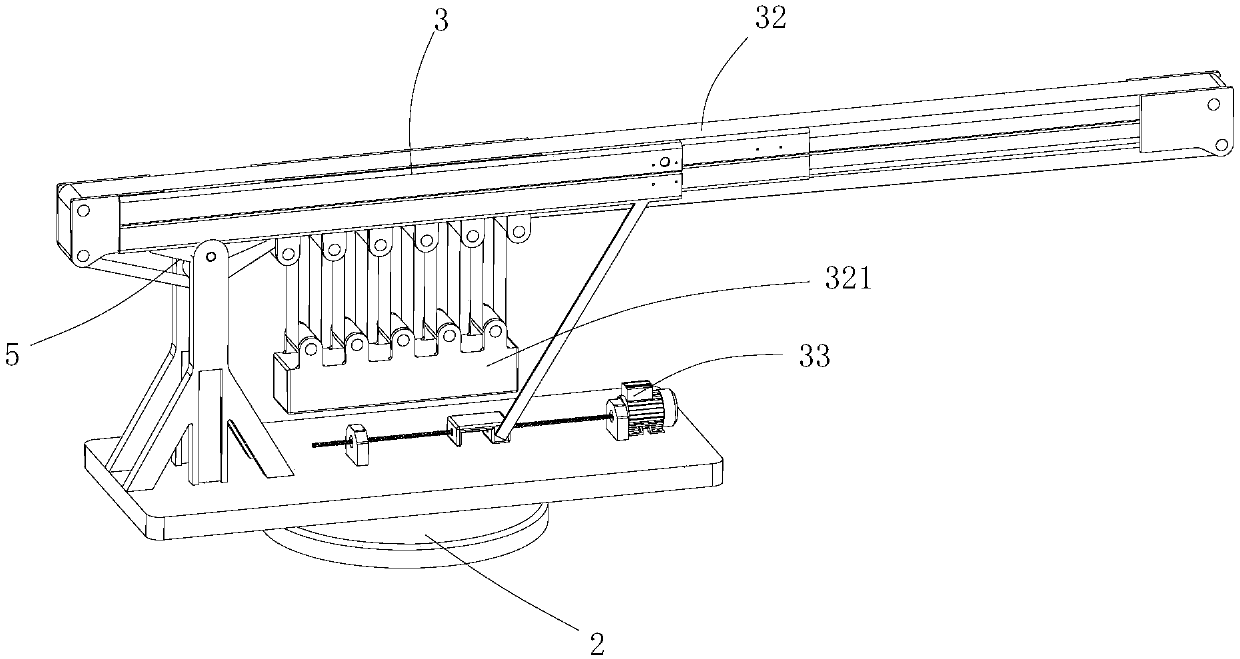

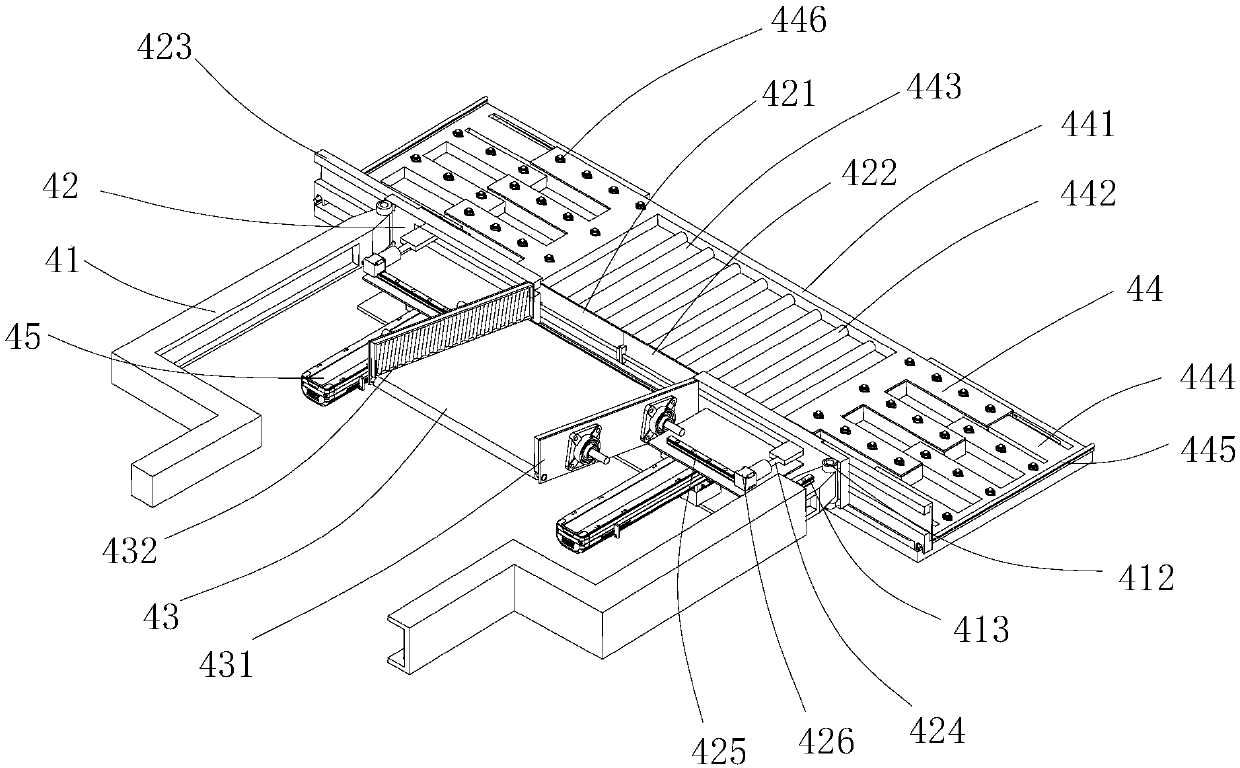

[0035] This embodiment provides a long arm robot, such as figure 1 -3, it includes a base 1, a rotary mechanism 2, a transmission device 3, and a clamp 4.

[0036] Such as figure 1 -2, wherein, the base 1 is provided with a fixed frame 11, and the fixed frame 11 is provided with an auxiliary support, and the rotary mechanism 2 is provided under the base 1, which includes a support seat 21, a rotary flange 22, and a driving motor. The support base 21 is fixedly arranged on the ground, the base 1 is connected to the support base 21 through the rotary flange 22, and the driving motor drives the support base 21 to perform rotary motion.

[0037] Transmission device 3, it comprises mechanical arm 31 and is located at the conveyer belt 32 on mechanical arm 31, is used to regulate the adjusting mechanism 33 of mechanical arm 31 pitch angles; Mechanical arm 31 is located on fixed frame 11, and adjusting mechanism 33 is arranged on base Seat 1. Wherein, mechanical arm 31 comprises b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com