Multi-axis manipulator

A manipulator and four-bar linkage technology, applied in cranes, load hanging components, transportation and packaging, etc., can solve the problems of high labor intensity, restricting the progress of construction enterprises, construction quality and economic benefits, and many potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

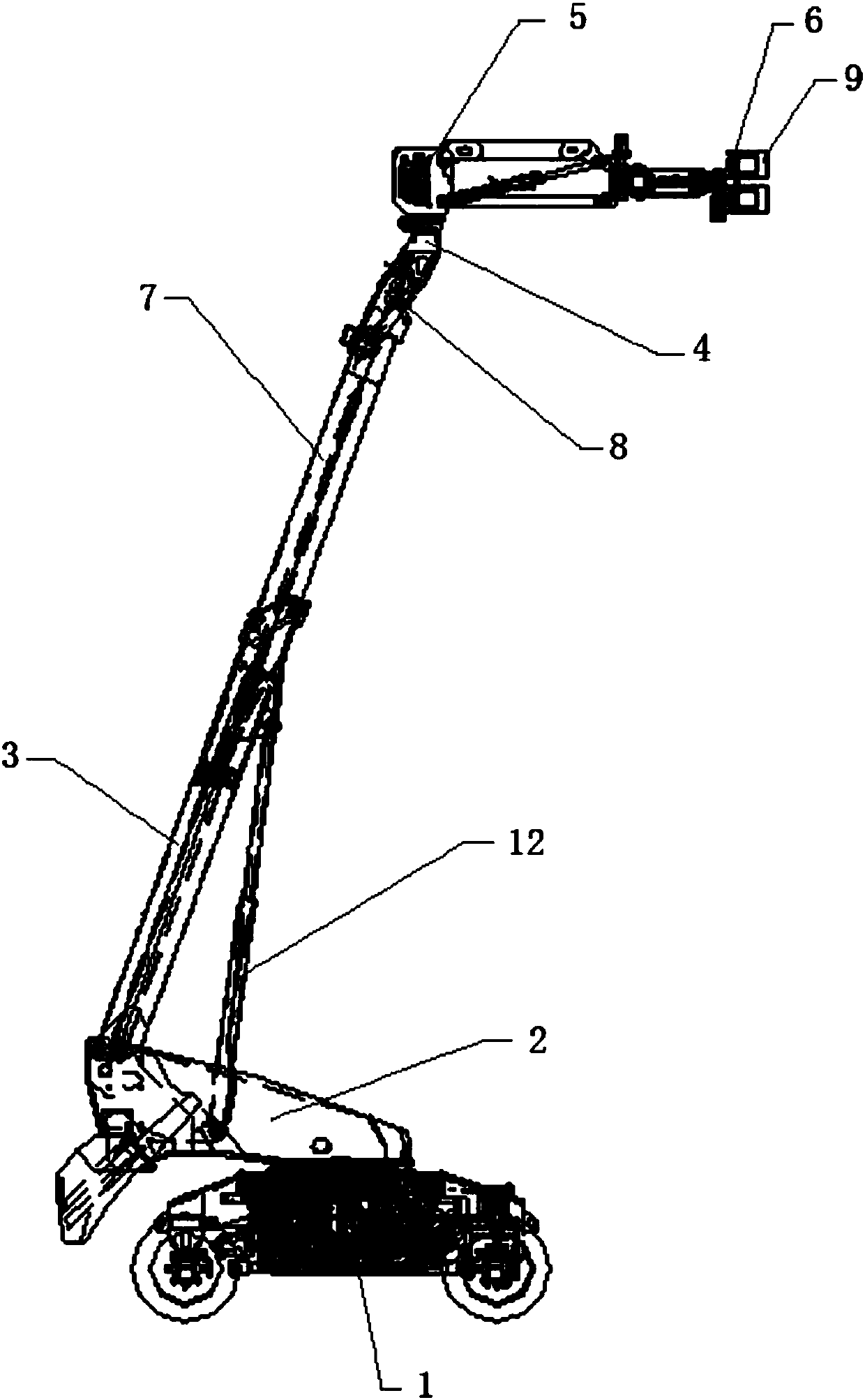

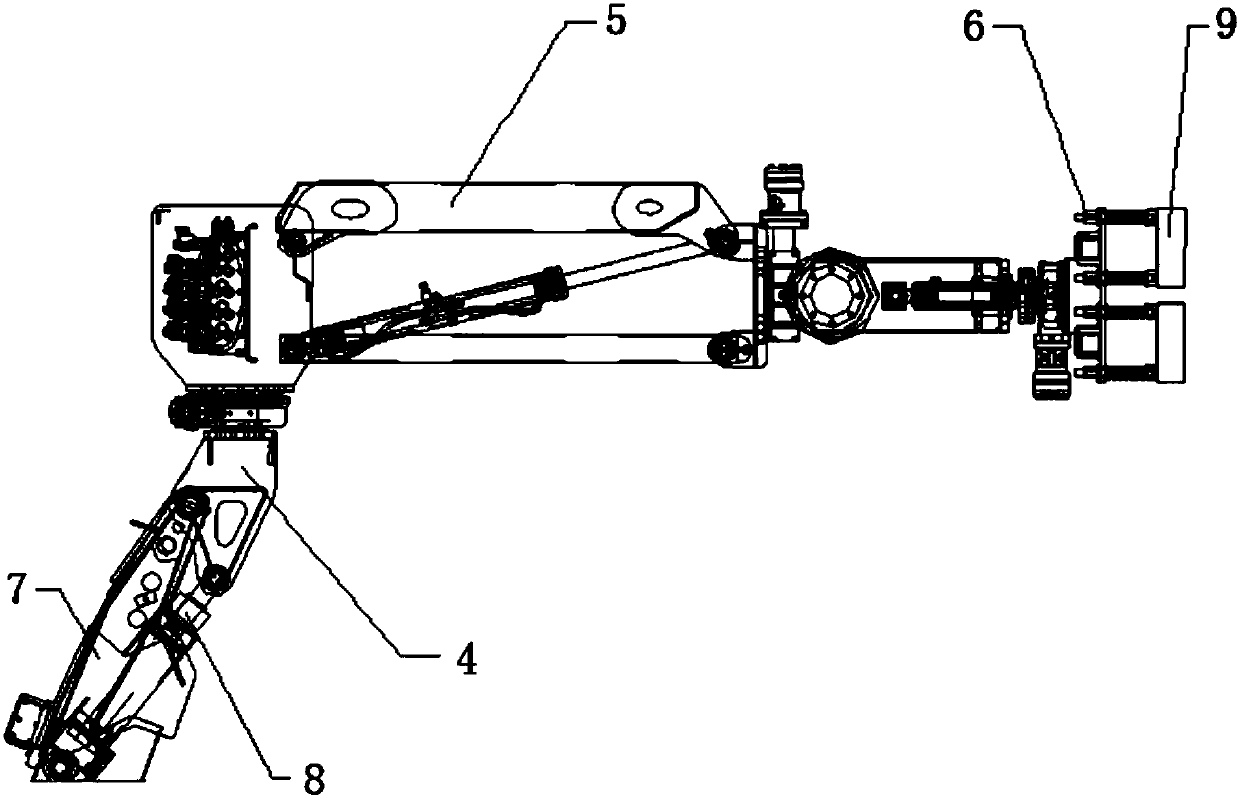

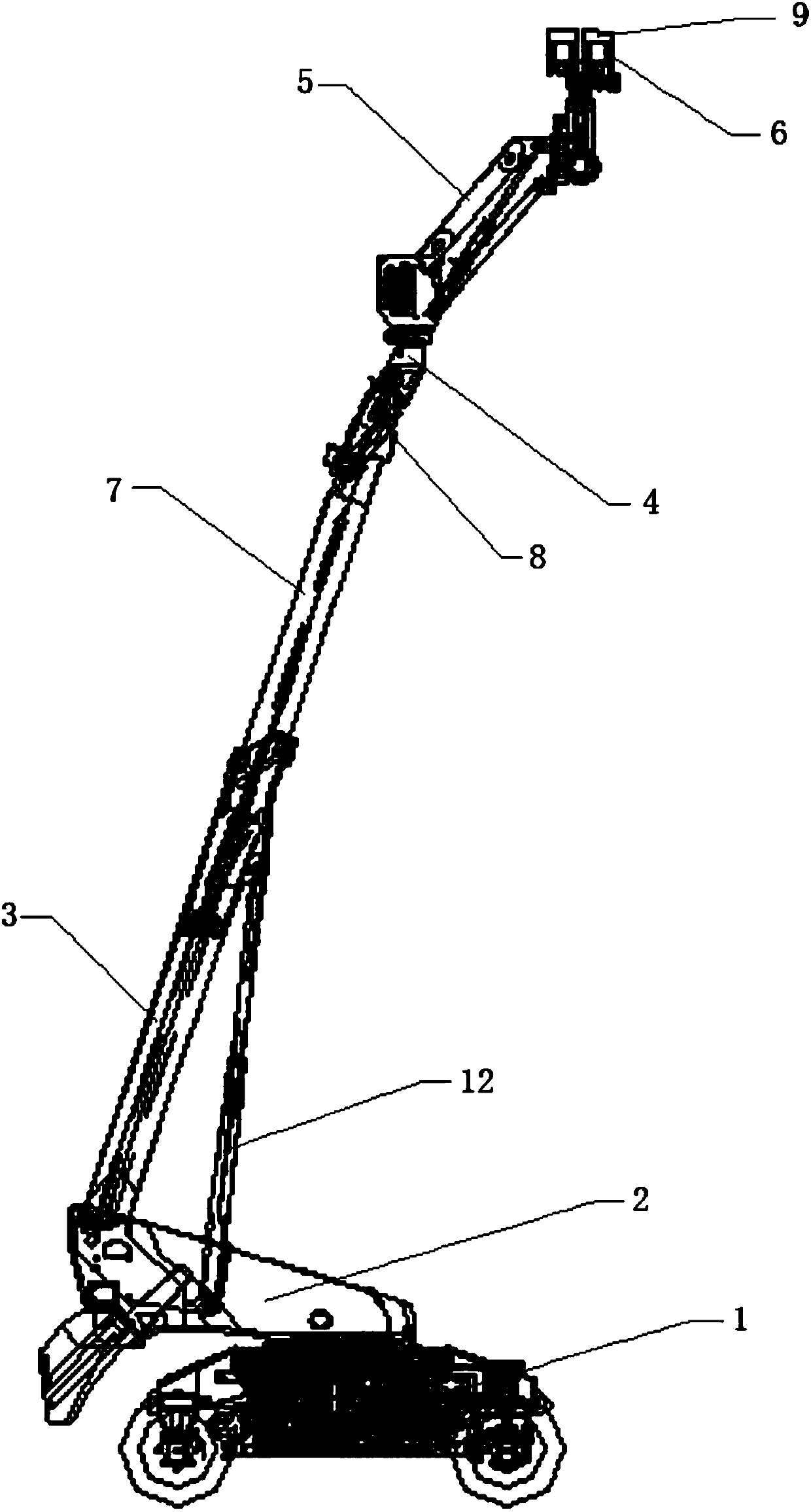

[0021] Such as Figure 1 to Figure 4 As shown, the template lifting operation trolley includes a traveling chassis 1, an upper mounting turntable 2, a telescopic boom 3, a leveling support 4 with a flat upper end surface, and a multi-axis that can rotate and extend The manipulator 5 and the electro-permanent magnetic chuck device 6, the top loading turntable 2 can be horizontally rotatably arranged on the traveling chassis 1, the bottom of the telescopic boom 3 is hinged with the rear of the top loading turntable 2, the telescopic The top of the telescopic arm 7 of the type boom 3 is hinged with the middle left part of the leveling support 4, and the telescopic shaft of the leveling cylinder 8 provided on the telescopic arm 7 is hinged with the bottom of the leveling support 4. One end of the shaft manipulator 5 is fixedly connected to the upper end surface of the leveling support 4, and the other end of the multi-axis manipulator 5 is fixedly connected to the electro-permanent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com