Device and method for preparing granular silicon seed crystal

A technology for granular silicon and seed crystals, which is applied in the field of devices for preparing granular silicon seed crystals, can solve the problems of increasing bed porosity, low minimum fluidized state velocity, and improved fluidized bed boiling degree, and achieves a small amount of material loss. , not easy to dust, the effect of high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

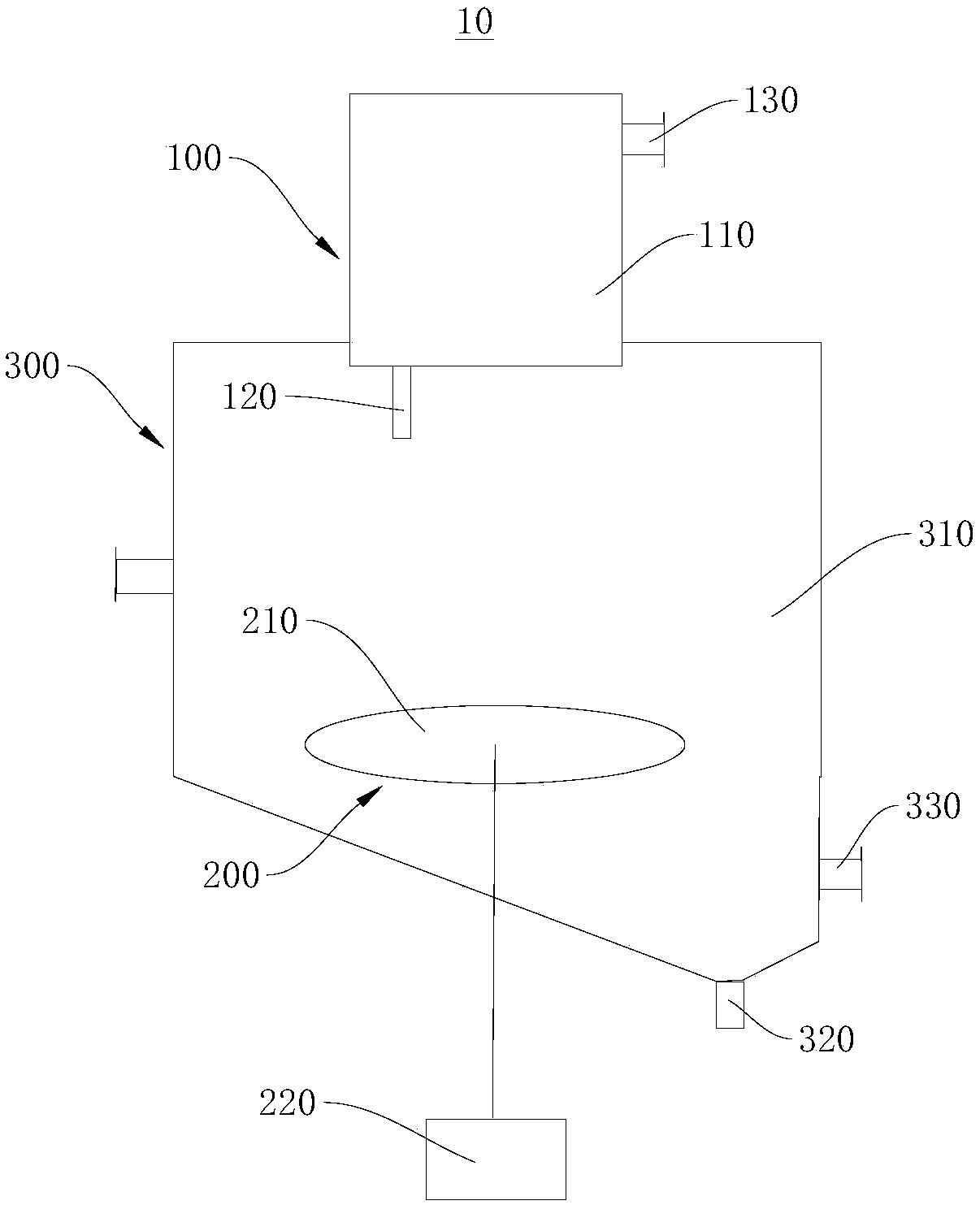

[0042] figure 1 It is a schematic diagram of the overall structure of the device 10 for preparing granular silicon seed crystals provided in Example 1 of the present invention. Please refer to figure 1 , the present embodiment provides a device 10 for preparing granular silicon seed crystals, which includes a melting device 100 for melting solid silicon material, and the melting device 100 includes a chamber 110 with a diversion port 120 . A rotating device 200 for dispersing the molten silicon flowing out through the diversion port 120 , the rotating device 200 includes a turntable 210 and a drive device 220 , the drive device 220 is connected to the turntable 210 in transmission; the diversion port 120 is opposite to the turntable 210 .

[0043] In this embodiment, the melting device 100 is provided with a high-purity gas replacement port 130 communicating with the containing chamber 110. The high-purity gas replacing port 130 is provided to facilitate the replacement of th...

Embodiment 2

[0064] This embodiment provides a method for preparing granular silicon seed crystals, which includes the following steps.

[0065] S1, melting step

[0066] The polysilicon material is heated to a molten state through the melting device 100 to obtain molten polysilicon. The temperature of the molten polysilicon was controlled at 2280°C.

[0067] S2, dispersion step

[0068] The molten polysilicon is dispersed into polysilicon droplets by the rotating device 200 .

[0069] S3, cooling step

[0070] Cool and solidify polysilicon droplets in the air to obtain granular silicon seed crystals.

Embodiment 3

[0072] This embodiment provides a method for preparing granular silicon seed crystals, which includes the following steps.

[0073] S1, melting step

[0074] The polysilicon material is heated to a molten state through the melting device 100 to obtain molten polysilicon. The temperature of the molten polysilicon was controlled at 2180°C.

[0075] S2, dispersion step

[0076] The molten polysilicon is dispersed into polysilicon droplets by the rotating device 200 .

[0077] S3, cooling step

[0078] Cool and solidify polysilicon droplets in the air to obtain granular silicon seed crystals.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap