A salty and oily waste water degreasing evaporation crystallizer

A technology for evaporating crystallizer and wastewater, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of complete structure and function, easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

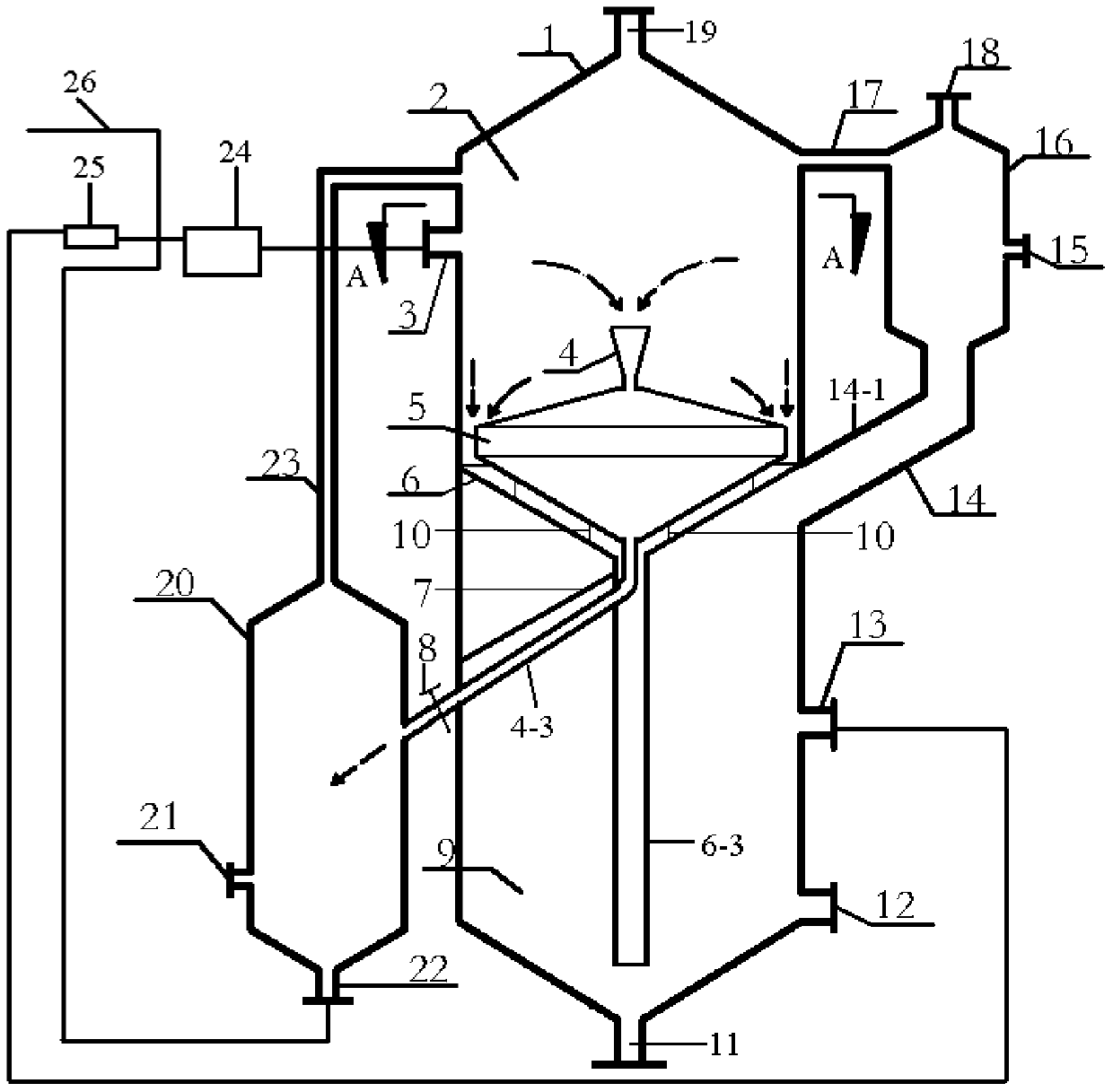

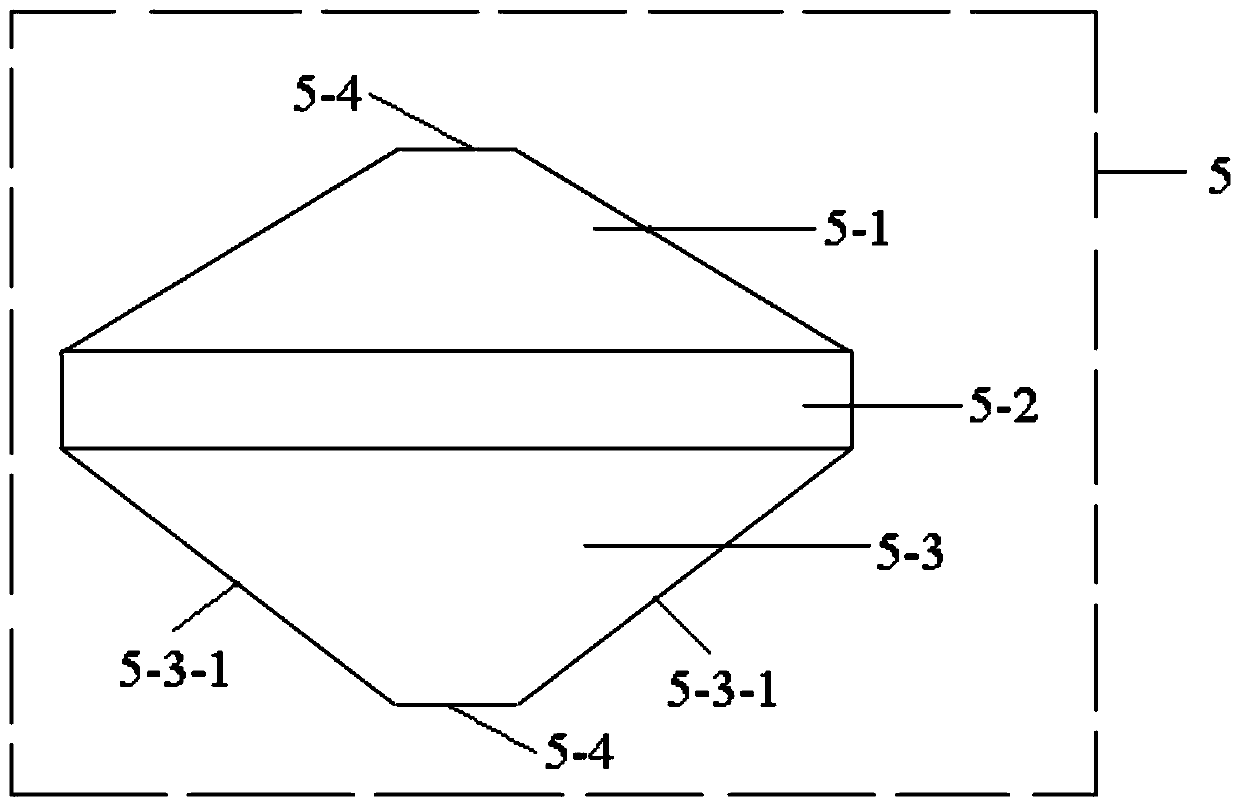

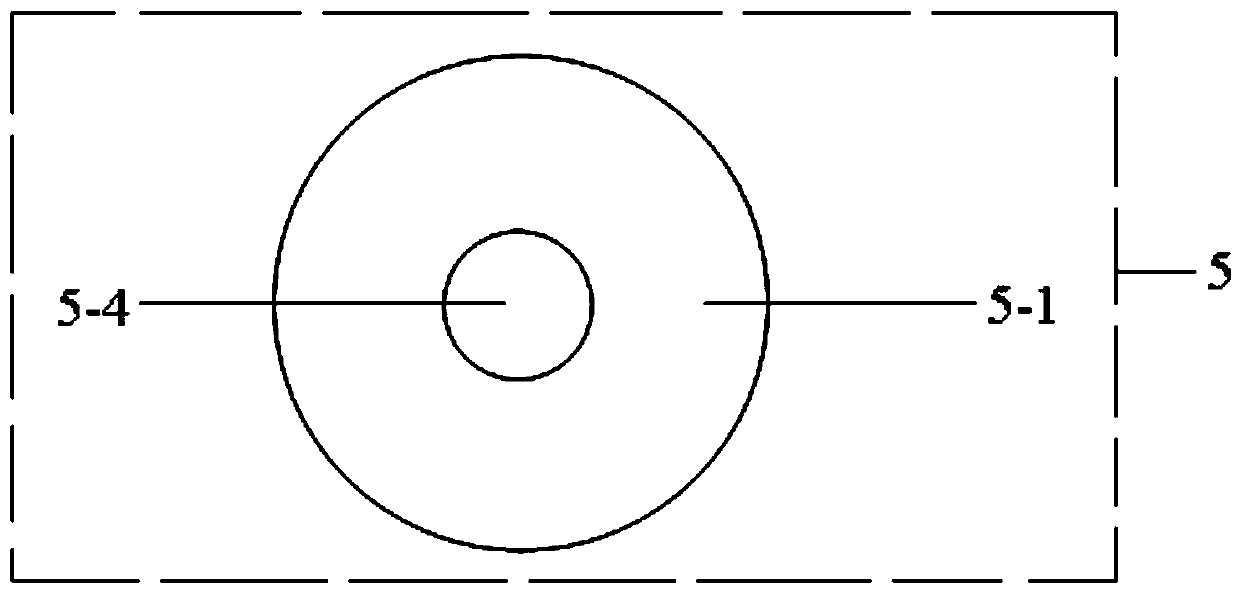

[0024] Specific implementation mode one: as Figure 1-7 , this embodiment is an evaporation crystallizer for removing oil from salty and oily wastewater, specifically composed of a cylinder body 1, a floating oil collection funnel 4 in the evaporation chamber, a baffle cone 5, a feeding collection funnel 6 in the crystallization chamber, a baffle plate 7, The crystallization chamber oil / water separation tank 16, the crystallization chamber oil / water separation tank communication pipe 17, the heat exchanger 24, the circulating pump 25, the evaporation chamber oil / water separation tank 20 and the evaporation chamber oil / water separation tank communication pipe 23;

[0025] The evaporation chamber oil / water separation tank 20 is arranged in the middle and lower part of the outside of the cylinder body 1, and the top of the evaporation chamber oil / water separation tank 20 communicates with the upper part of the cylinder body 1 through the evaporation chamber oil / water separation ta...

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the cone angle of the feed collection funnel 6 in the crystallization chamber is 100°-120°. Others are the same as the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 1 is that: the cone angle of the first circular frustum 5 - 1 of the baffle cone 5 is 120°-150°. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com