Fully-integrated spring operating mechanism for high-voltage alternating-current circuit breaker

A high-voltage AC and operating mechanism technology, applied in high-voltage air circuit breakers, protective switch operation/release mechanisms, high-voltage/high-current switches, etc., to achieve high cost performance, high reliability, and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

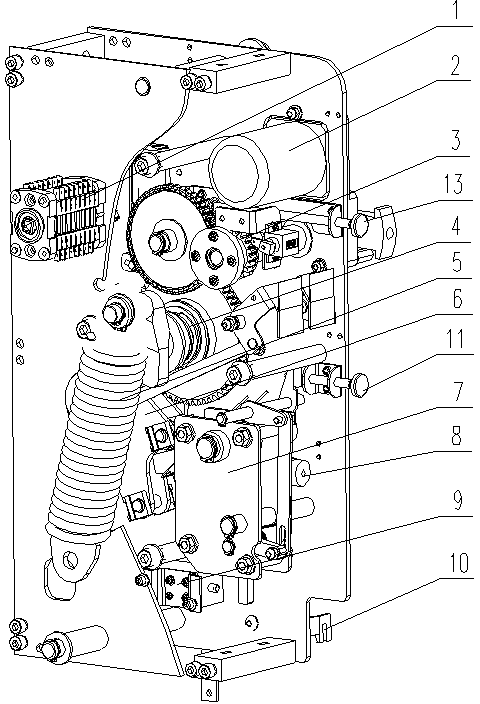

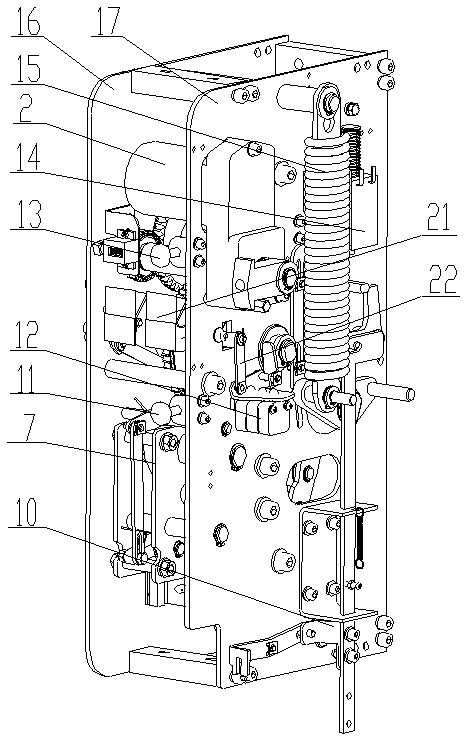

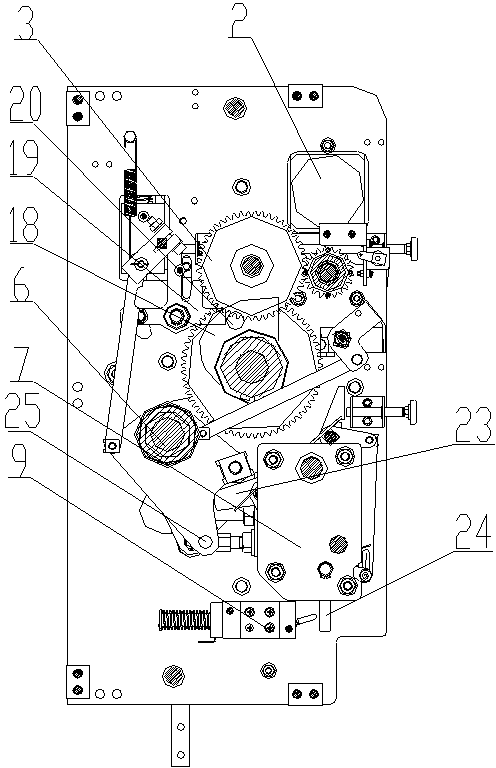

[0009] Such as Figure 1 to Figure 3 As shown, the auxiliary switch 1 of the fully integrated spring operating mechanism of the high-voltage AC circuit breaker is fixed on the left side plate 16 of the mechanism with bolts, the energy storage motor 2 is fixed on the right side plate 17 of the mechanism with bolts, the gear pair 3, the energy storage shaft 4 and the output shaft 6 are both supported by the left side plate 16 and the right side plate 17 of the mechanism, the upper end of the energy storage spring 5 is connected with the energy storage shaft 4, and the closing holding module 7 is positioned on the left side plate 16 of the mechanism and the right side of the mechanism Between the plates 17, the buffer 8 is fixed on the right side plate 17 of the mechanism with bolts, the opening electromagnet 9 is fixed on the left side plate 16 of the mechanism with screws, and the opening spring 15 connected with the opening electromagnet 9 is controlled to fix the mechanism On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com