Organic fertilizer for strawberries and preparation method of organic fertilizer

An organic fertilizer and strawberry technology, applied in the field of strawberry organic fertilizer and its preparation, can solve the problems of strong drug resistance, low fertilizer utilization rate, long strawberry continuous cropping time, etc., and achieve the effect of increasing yield and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

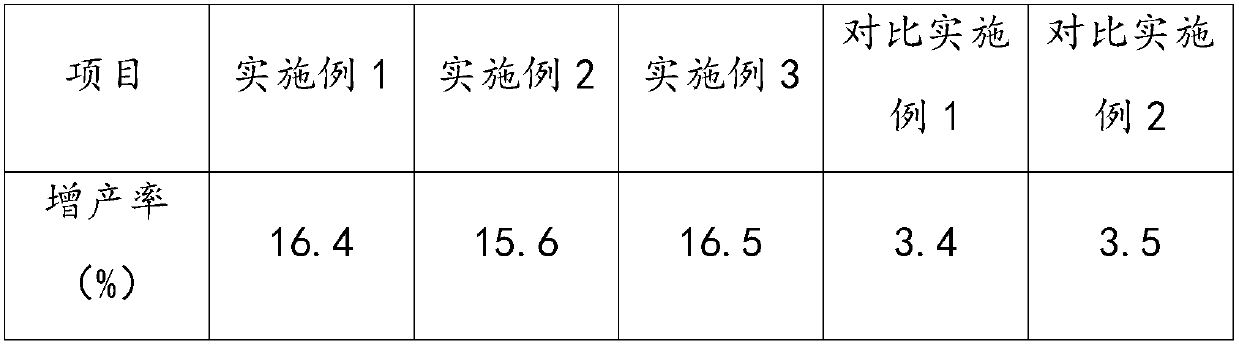

Examples

Embodiment 1

[0020] A. Mix 10kg of sawdust, 5kg of sheep manure, 1kg of sargassum, 2kg of corn stalk powder, 3kg of cassava residue, 10kg of peanut shell powder, 1kg of distiller’s grains, and 1kg of glucose, and add them to a film-sealed fermentation tank at 20°C for 5 days. get fermented material;

[0021] B. Mix 1 kg of tea seed cake and 10 kg of sesame cake evenly, add ethanol with a volume concentration of 60%, and the amount of ethanol added is 50% of the total weight of the sesame cake, soak for 3 hours at 50°C, and then soak at 30°C Soak for 1h, filter to obtain the mixture of tea seed cake and sesame cake;

[0022] C. Dry and sieve the mixture of tea seed cake and sesame cake obtained in step B to 300 meshes, and then mix with the fermented material obtained in step A to obtain this product.

Embodiment 2

[0024] A. Mix 15kg of wood chips, 8kg of sheep manure, 3kg of sargassum, 3kg of corn stalk powder, 5kg of cassava residue, 15kg of peanut shell powder, 3kg of distiller's grains, and 3kg of glucose, and add them to a film-sealed fermenter for 8 days at 25°C. get fermented material;

[0025] B. Mix 2 kg of tea seed cake and 15 kg of sesame cake evenly, add ethanol with a volume concentration of 80%, and the amount of ethanol added is 65% of the total weight of sesame cake, soak for 3.5 hours at a temperature of 55°C, and then soak at a temperature of 35°C Soak down for 1.5h, filter to obtain the mixture of tea seed cake and sesame cake;

[0026] C. Dry and sieve the mixture of tea seed cake and sesame cake obtained in step B to 400 meshes, and then mix with the fermented material obtained in step A to obtain the product.

Embodiment 3

[0028] A. Mix 20kg of sawdust, 10kg of sheep manure, 5kg of sargassum, 4kg of corn stalk powder, 6kg of cassava residue, 20kg of peanut shell powder, 5kg of distiller's grains, and 5kg of glucose, and add them to a film-sealed fermenter for 10 days at 30°C. get fermented material;

[0029] B. Mix 3 kg of tea seed cake and 20 kg of sesame cake evenly, add ethanol with a volume concentration of 90%, and the amount of ethanol added is 80% of the total weight of the sesame cake, soak for 4 hours at 60°C, and then soak at 40°C Soak for 2h, filter to obtain the mixture of tea seed cake and sesame cake;

[0030] C. Dry and sieve the mixture of tea seed cake and sesame cake obtained in step B to 500 meshes, and mix with the fermented material obtained in step A to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com