Friction body protection pad for brake pad and brake pad

A technology of brake pads and protective pads, which is applied to brakes with pressurized braking surfaces, friction linings, brake components, etc., can solve problems affecting the braking performance and service life of brake pads, wear and deformation and other problems to achieve the effect of improving connection reliability, improving the degree of fit, and ensuring connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

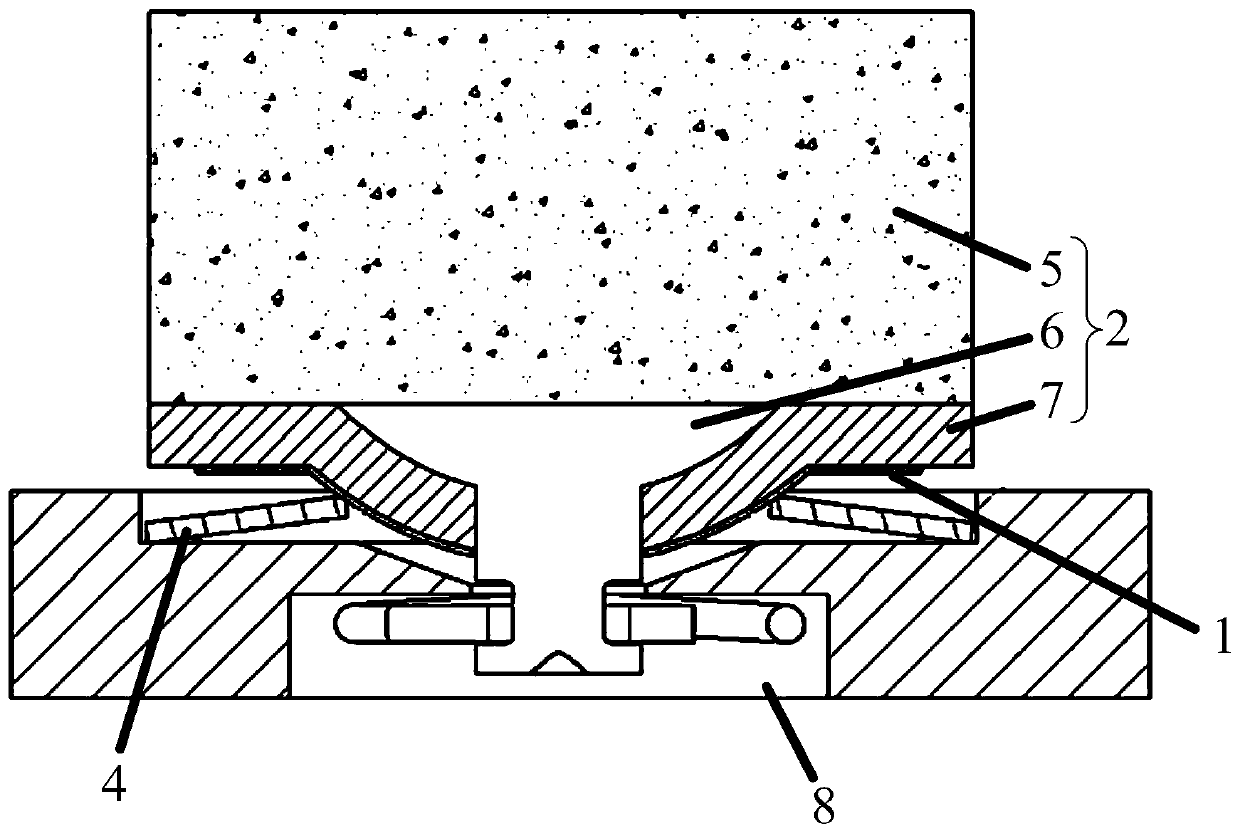

[0043] A brake pad is described, such as figure 1 and Figure 4 As shown, it includes a friction block 2 and a brake back plate 3 that are arranged corresponding to each other. The brake back plate 3 is provided with an elastic support 4 that applies a biasing force toward the friction block 2 away from the brake back plate 3, and is arranged on the friction The protection pad 1 between the block 2 and the elastic support 4, and the hardness of the protection pad 1 is greater than that of the elastic support 4. A protective pad made of heat-resistant stainless steel whose hardness is greater than that of the elastic support is set between the friction body of the brake pad and the elastic support, so that the protective friction block will not float up and down or rotate in a small range during the braking process. Grooves are formed by being squeezed by the elastic support, causing the friction block and the brake disc to be unable to fully fit, affecting the braking perfor...

Embodiment 2

[0047] A brake pad is described, such as figure 1 and Figure 4 As shown, it includes a friction block 2 and a brake back plate 3 that are arranged corresponding to each other. The brake back plate 3 is provided with an elastic support 4 that applies a biasing force toward the friction block 2 away from the brake back plate 3, and is arranged on the friction The protection pad 1 between the block 2 and the elastic support 4, and the hardness of the protection pad 1 is greater than that of the elastic support 4.

[0048] In this example, if figure 1 The friction block 2 shown includes a friction body 5, a connection part 6 arranged on the friction body 5 for connecting the brake pad back plate 3, and a friction body back plate 7 arranged on the lower surface of the friction body 5; the connection part 6 It includes a connection end 10 fixedly connected to the lower surface of the friction body 5 , and a connecting rod 11 inserted into the brake pad back plate 3 and connecte...

Embodiment 3

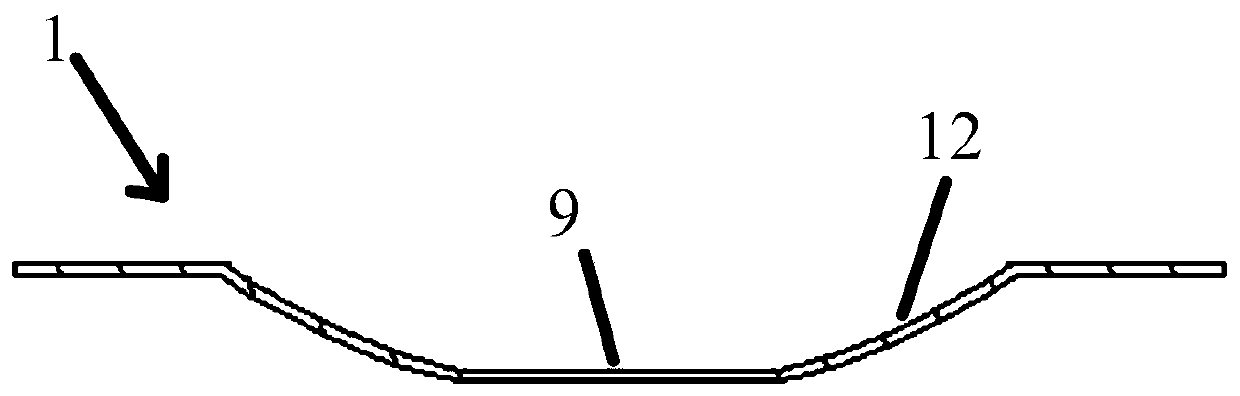

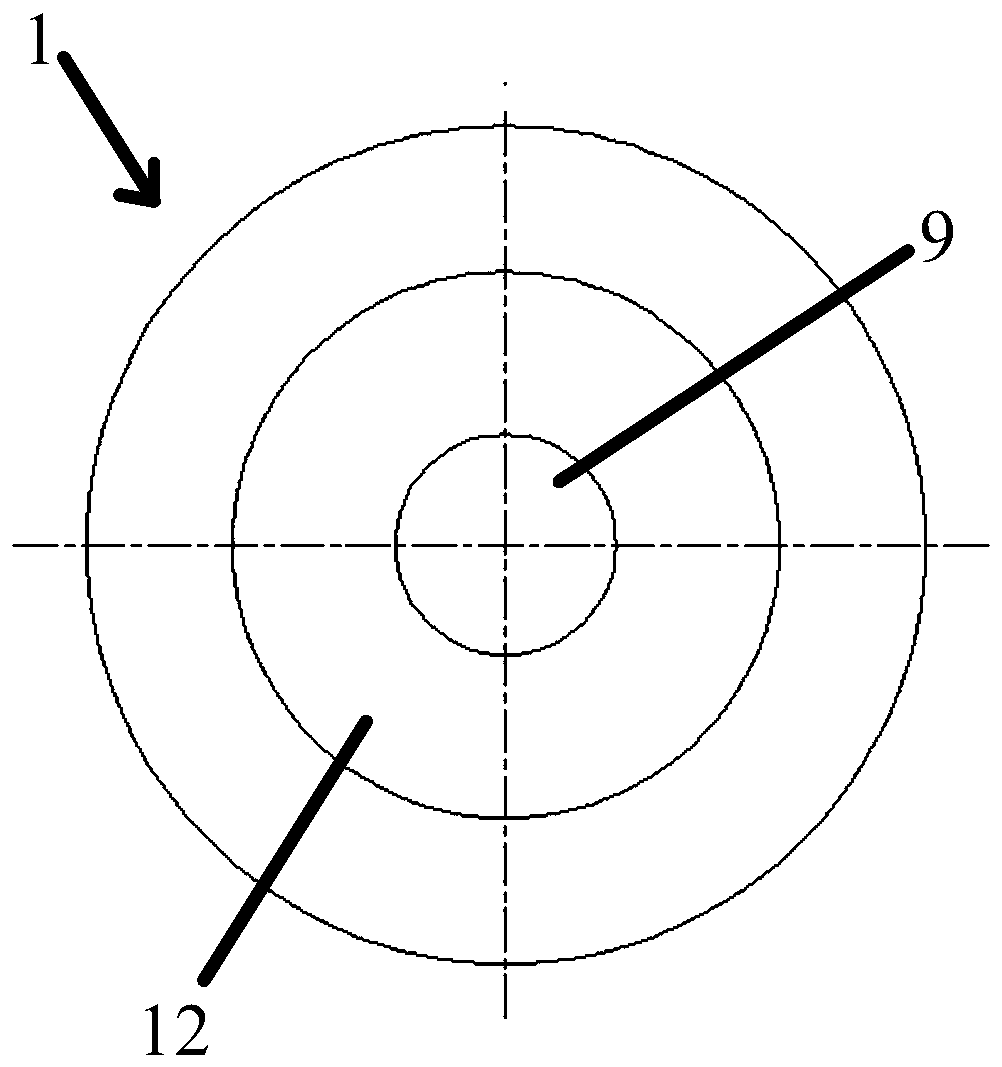

[0052] A brake pad is described, such as Figure 5 and Figure 4 As shown, it includes a friction block 2 and a brake back plate 3 that are arranged corresponding to each other. The brake back plate 3 is provided with an elastic support 4 that applies a biasing force toward the friction block 2 away from the brake back plate 3, and is arranged on the friction The protection pad 1 between the block 2 and the elastic support 4, and the hardness of the protection pad 1 is greater than that of the elastic support 4.

[0053] In this example, if Figure 5 The friction block 2 shown includes a friction body 5, a connection part 6 arranged on the friction body 5 for connecting the brake pad back plate 3, and a friction body back plate 7 arranged on the lower surface of the friction body 5; the connection part 6 It includes a connection end 10 fixedly connected to the lower surface of the friction body 5 , and a connecting rod 11 inserted into the brake pad back plate 3 and connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com