CNC (computer numerical control) shock-resistant remote control

A remote control and remote control technology, applied in the CNC field, can solve the problems of reduced production efficiency, cumbersome, insensitive remote control response, etc., to achieve the effect of convenient use, prevent damage, provide stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

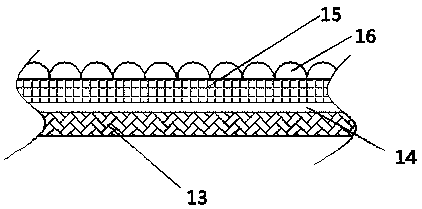

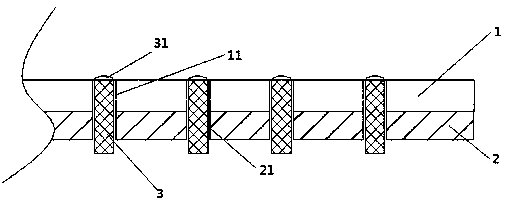

[0023] A CNC remote control anti-seismic remote control, comprising an outer shell 1, an inner shell 2, and buttons 3, the inner shell 2 is sleeved inside the outer shell 1, and a number of first through holes 11 are evenly arranged on the front of the outer shell 1 , the front of the inner shell 2 is evenly arranged with a number of second through holes 21, the first through holes 11 and the second through holes 21 are set correspondingly; the outer shell 1 is sequentially composed of a first buffer layer 13, a hollow interlayer 14 , the second buffer layer 15 and the third buffer layer 16, the first buffer layer 13 and the second buffer layer 15 are magnet layers, and the magnetic repulsion between the first buffer layer 13 and the second buffer layer 15 , the third buffer layer 16 is a silica gel layer.

[0024] In the present invention, when the remote controller accidentally falls, the first step of buffering is realized through the action of the silica gel layer of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com