Topological structure of high-power density power electronic transformer and control method for topological structure

A high power density, power electronics technology, applied in the field of power transformation, can solve the problems of high cost, low power density, large volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

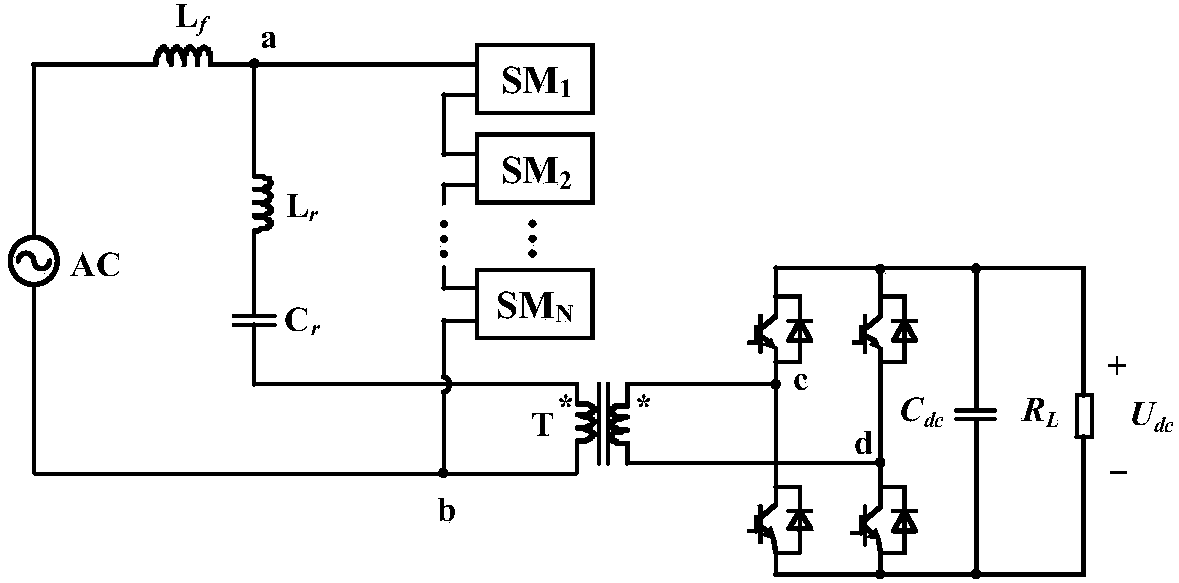

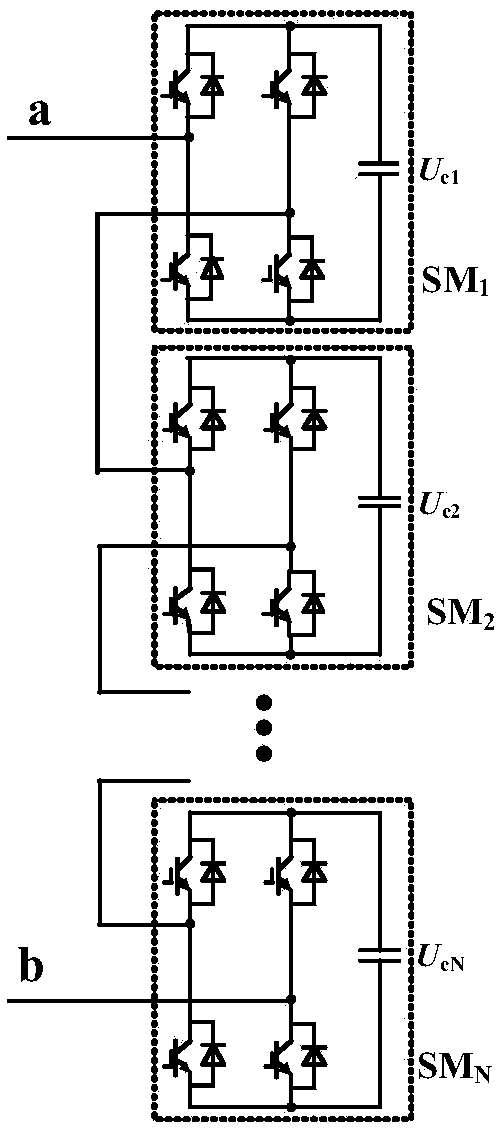

[0070] like figure 1 The high power density power electronic transformer topology shown is composed of a high-voltage AC stage, a high-frequency isolation transformer, and a low-voltage DC stage. The high-voltage AC stage adopts a new topology, and the high-voltage AC power supply passes through the filter inductor L f After that, it is connected to the input terminal a of N cascaded full-bridge sub-modules, and the input terminal a is connected to the middle point of the left bridge arm of the first full-bridge sub-module. like figure 2 As shown, the middle point of the right bridge arm of the first full-bridge sub-module is connected to the middle point of the left bridge arm of the second full-bridge sub-module, and so on, the middle of the right bridge arm of the N-1th full-bridge sub-module point is connected to the middle point of the left bridge arm of the Nth full-bridge sub-module, and the middle point of the right bridge arm of the N-th full-bridge sub-module is co...

Embodiment 2

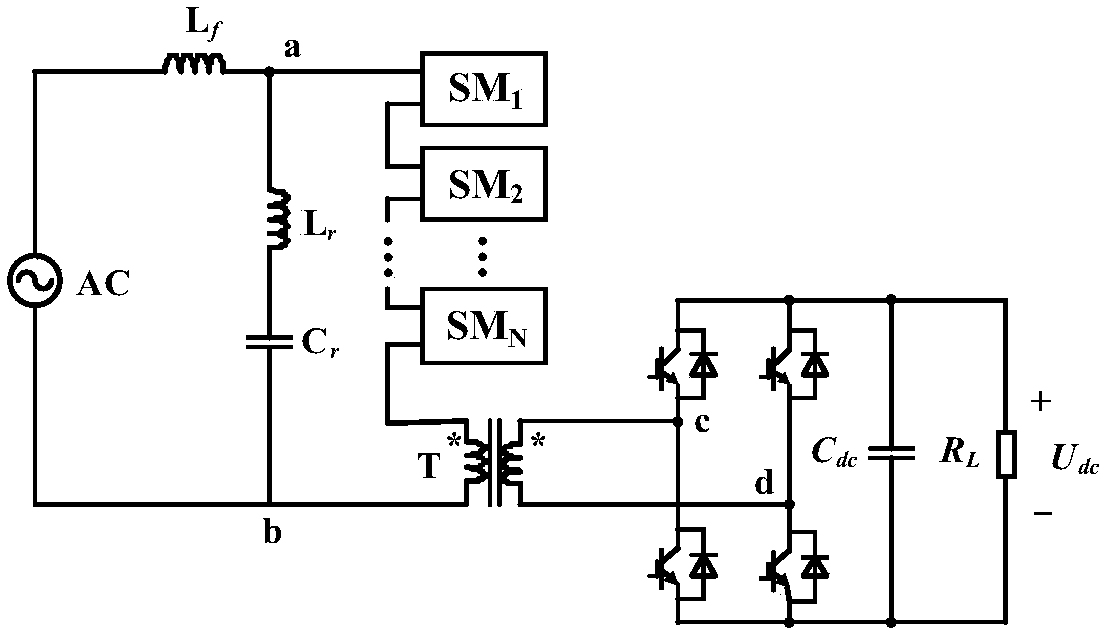

[0072] This example is extended and changed on the basis of the first example. The entire topology is still composed of a high-voltage AC stage, a high-frequency isolation transformer, and a low-voltage DC stage, such as image 3 shown. High-voltage AC power passes through the filter inductor L f Connect to the input terminal a of N cascaded full-bridge submodules afterwards, the structure of N cascaded full-bridge submodules is consistent with that described in Embodiment 1, and the output of N cascaded full-bridge submodules is the same as the high The same-named end of the primary side of the frequency isolation transformer is connected, and the different-named end of the original side of the high-frequency isolation transformer is connected back to the high-voltage AC power supply. L r C r One end of the series resonant circuit is connected to the input end a of the N cascaded full-bridge sub-modules, and the other end is connected to the different-named end b of the p...

Embodiment 3

[0075] like Figure 4 (a), Figure 4 As shown in (b), the entire topology is still composed of a high-voltage AC stage, a high-frequency isolation transformer, and a low-voltage DC stage, and the number of cascaded full bridges on the high-voltage side, LC series circuits, high-frequency isolation transformers, and H-bridges on the low-voltage side The number is multiples of the topology described in Embodiment 1 or Embodiment 2. When two bridge arms of each phase of the high-voltage AC stage circuit are connected in series with the topological structures described in Embodiment 1, each phase of the bridge arm of the high-voltage AC stage circuit is composed of 2N cascaded full-bridge sub-modules. High-voltage AC power passes through the filter inductor L f Then connect to the input terminal a1 of 2N cascaded full-bridge sub-modules, the structure of the 2N cascaded full-bridge sub-modules is consistent with that described in Embodiment 1, and the output terminal b2 of the 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com