Connecting module for wine making raw material cleaning

A technology for connecting components and raw materials, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of troublesome operation, difficult to clean, and the connection method is not suitable, and achieves the effect of simple structure and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

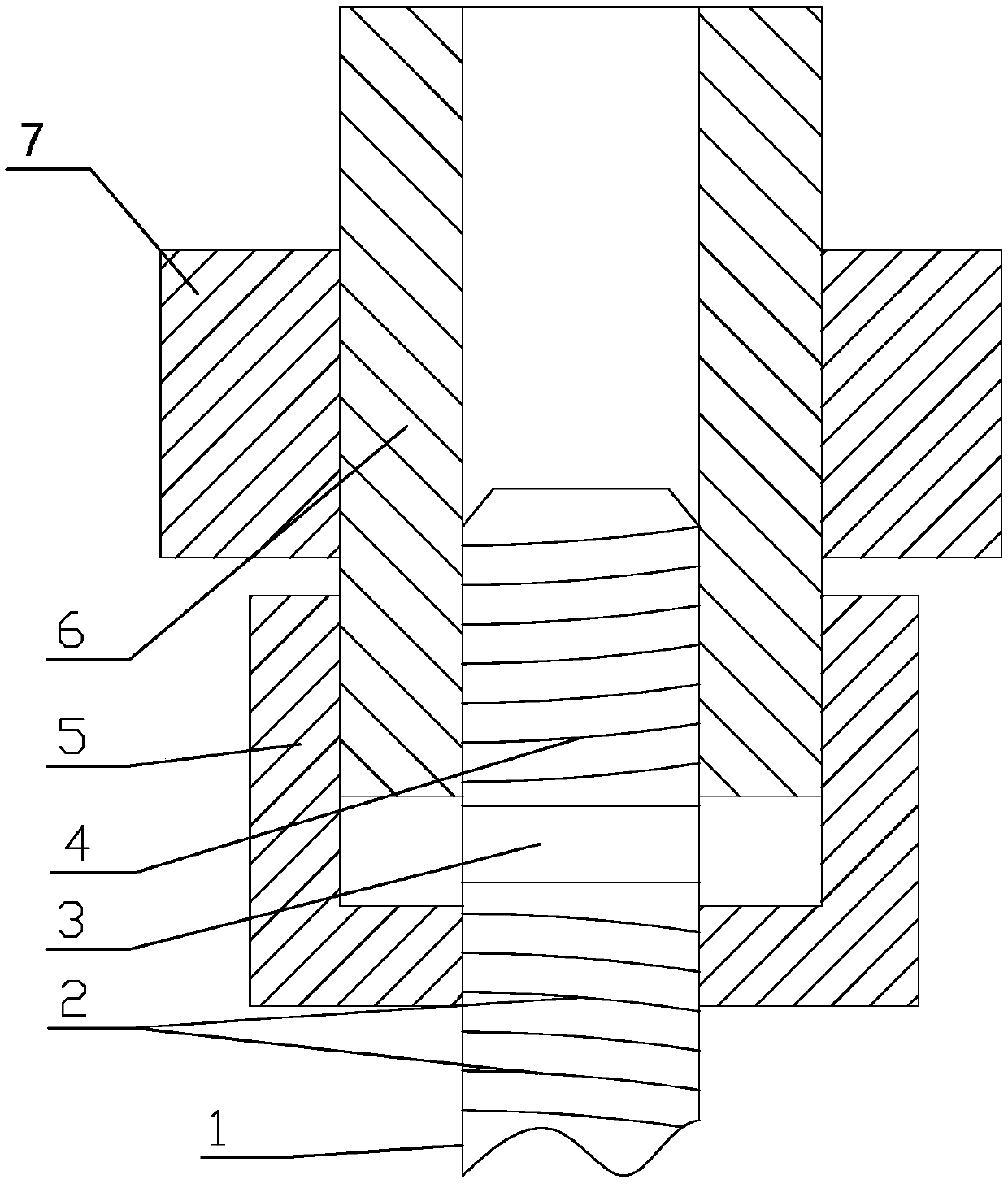

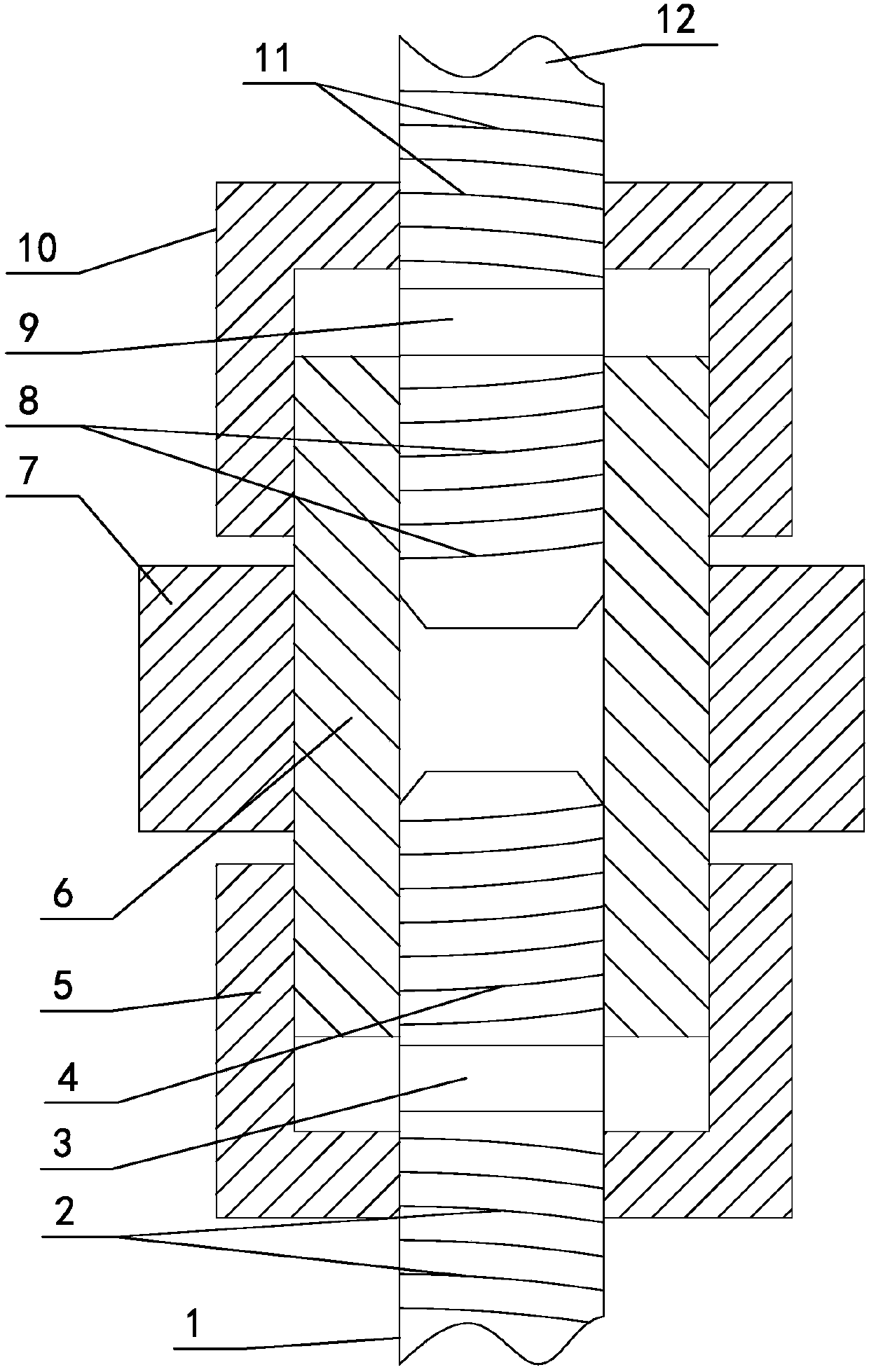

[0016] As shown, the connecting assembly used for cleaning the brewing raw materials includes a vertically arranged threaded pipe 6, a lower connecting rod 1 is installed in the lower half of the threaded pipe 6, and the inner pipe of the lower connecting rod 1 and the threaded pipe 6 The wall is threaded, and the thread on the lower connecting rod 1 that matches the threaded pipe 6 is a section of lower right-handed thread 4; The lower left-handed thread 2; the lower connecting rod 1 is covered with the lower threaded sleeve 5 threaded with the lower left-handed thread 2; the lower half of the lower threaded sleeve 5 is set on the lower connecting rod 1, and is threadedly connected with the lower left-handed thread 2 ; The upper half of the lower threaded sleeve 5 is set on the threaded pipe 6, and is threadedly connected with the threaded pipe 6.

[0017] In this embodiment, the lower connecting rod 1 between the lower left-handed thread 2 and the lower right-handed thread 4...

Embodiment 2

[0020] Changes are made on the basis of Example 1, such as figure 2 As shown, an upper connecting rod 12 is installed in the upper half of the threaded pipe 6, and the upper connecting rod 12 is threadedly matched with the inner pipe wall of the threaded pipe 6, and the thread matched with the threaded pipe 6 on the upper connecting rod 12 is A section of upper right-handed thread 8; on the upper connecting rod 12 above the upper right-handed thread 8, a section of upper left-handed thread 11 opposite to that of the upper right-handed thread 8 is set; The upper threaded sleeve 10 that thread 11 thread fits; the lower half of the upper threaded sleeve 10 is set on the threaded pipe 6, and is threadedly connected with the threaded pipe 6; the upper half of the upper threaded sleeve 10 is sleeved on the upper connecting rod 12, and It is threadedly connected with the upper left-handed thread 11; the upper connecting rod 12 between the upper right-handed thread 8 and the upper th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com