Straddle typemonorail train and double-shaft bogie thereof

A straddle-type monorail and bogie technology, which is applied in the direction of bogies, monorail systems, and devices for lateral relative movement between the chassis and bogies, can solve problems such as unfavorable car body vibration and difficulty in matching stiffness parameters, and achieve The effect of good running quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

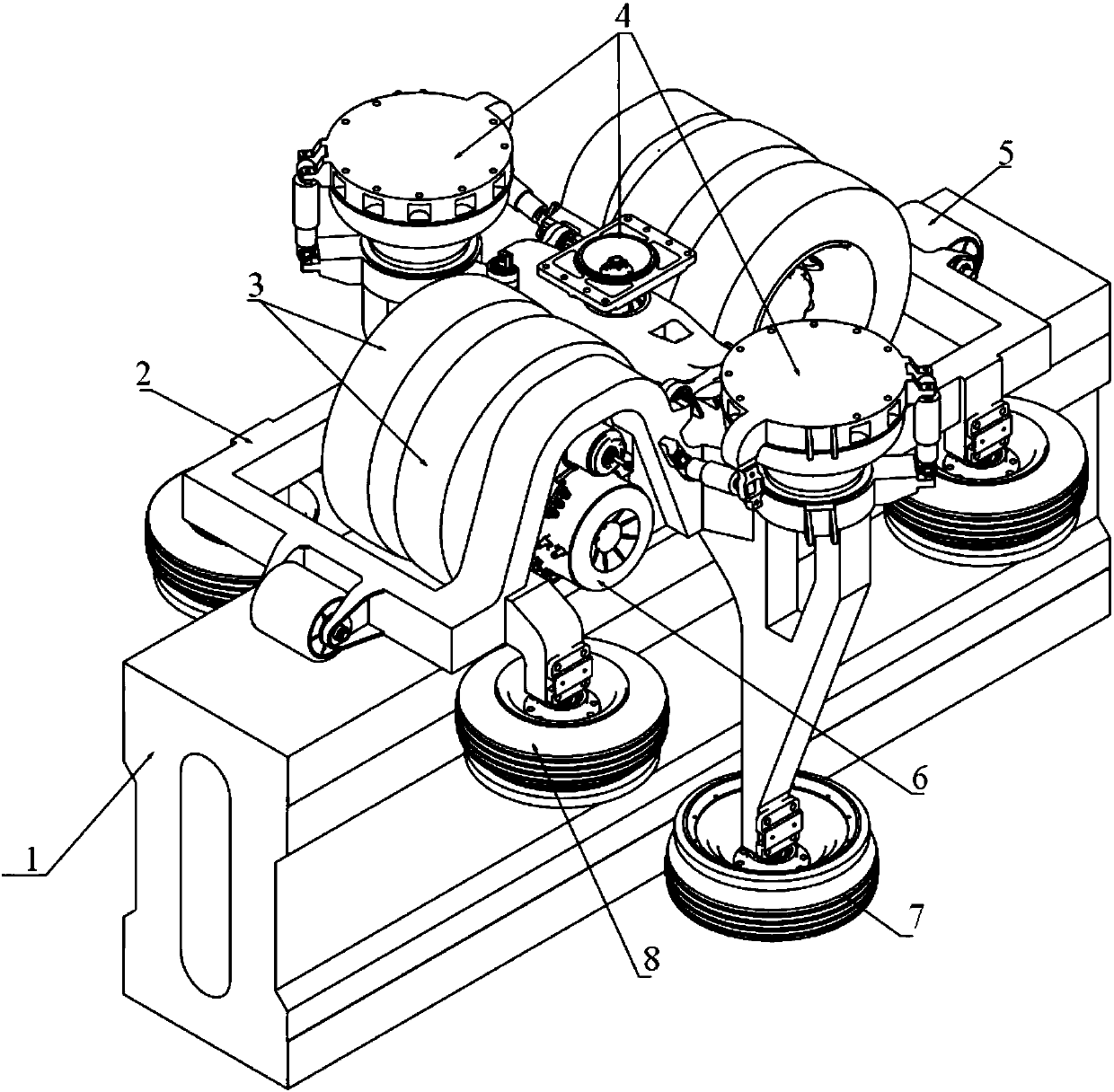

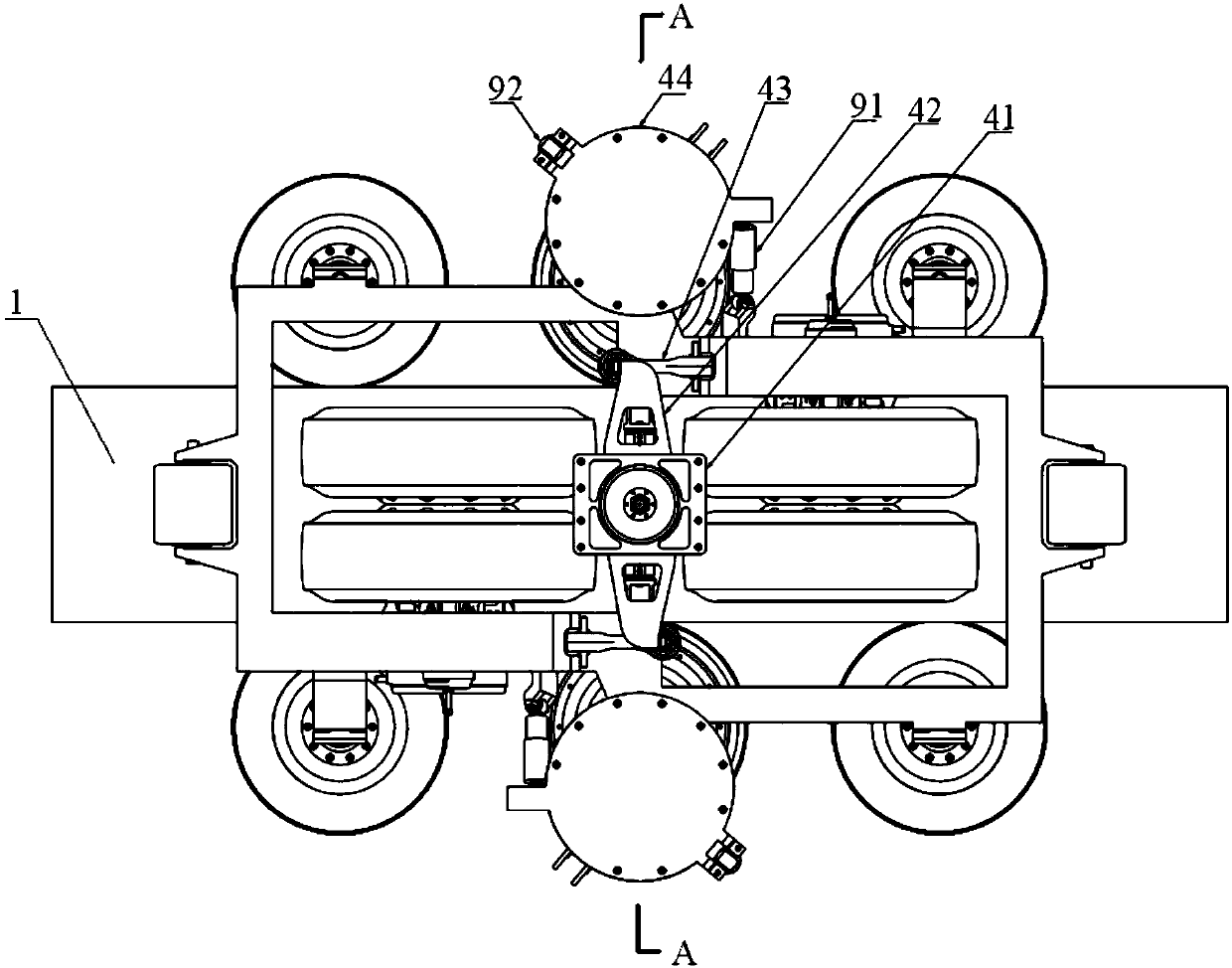

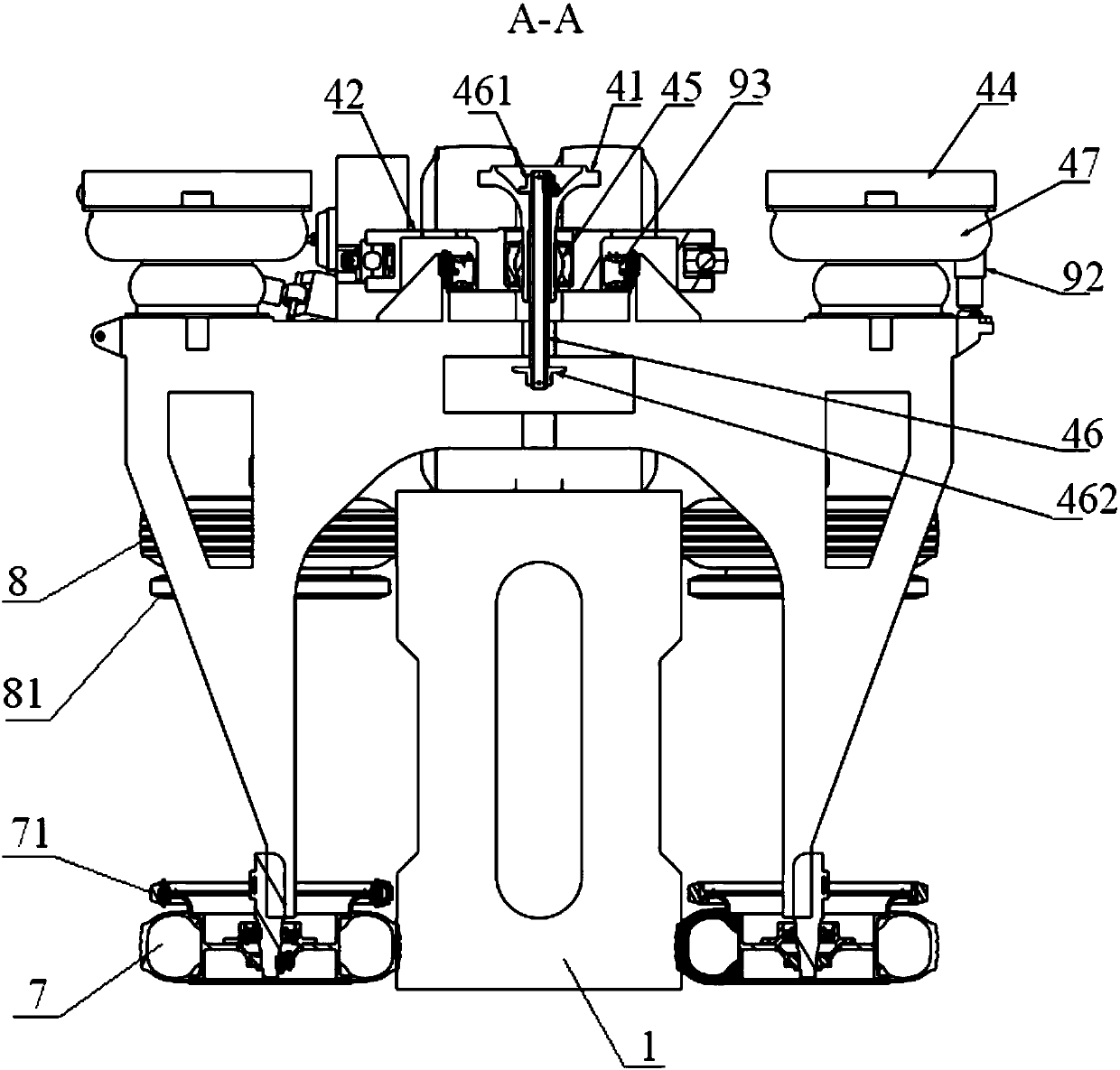

[0027] see Figure 1 ~ Figure 3 , figure 1 It is a schematic layout diagram of a double-axle bogie used for a straddle-type monorail train provided by Embodiment 1 of the present invention; figure 2 yes figure 1 is a top view; image 3 yes figure 2 Middle A-A sectional view.

[0028] The double-axle bogie provided by Embodiment 1 includes a car body connection device 4 installed above the beam (not marked in the figure) of the frame body 2. The car body connection device 4 includes a traction pin 41 for fixed connection with the car body. The pin seat 42 on which the traction pin 41 is installed and the traction rod 43 arranged at both ends of the pin seat 42 are connected to the frame body 2 and the pin seat 42 through rubber joints at both ends of the traction rod 43 .

[0029] The traction pin 41 is installed on the pin seat 42 through the sliding bearing 45, and the upper end of the traction pin 41 is fixedly connected with the vehicle body, and the longitudinal for...

Embodiment 2

[0041] The difference between the second embodiment and the first embodiment is that the installation structure between the driving device 6 and the frame body 2 is different. In the second embodiment, in order to install the driving device 6 on the frame body 2, the gear box 62 is provided with Match the flange with the side surface of the arched side beam 23, and fix the driving device 6 to the arched side beam 23 through the installation hole on the flange.

[0042] The present invention also provides a straddle-type monorail train, which includes the double-axle bogie disclosed in the above embodiments. Since the double-axle bogie disclosed in the above-mentioned embodiment has the above-mentioned technical effect, the straddle-type monorail train having the double-axle bogie also has the above-mentioned technical effect, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com