A multi-stage cold air cooling device for electronic devices

A technology for electronic devices and heat sinks, which is applied to the field of multi-stage cold air heat sinks for electronic devices, can solve the problems of undetermined radiator structure fans, complicated calculations, and large volume of water-cooled heat sinks, so as to improve heat dissipation effect and facilitate installation. , the effect of improving the degree of automation and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

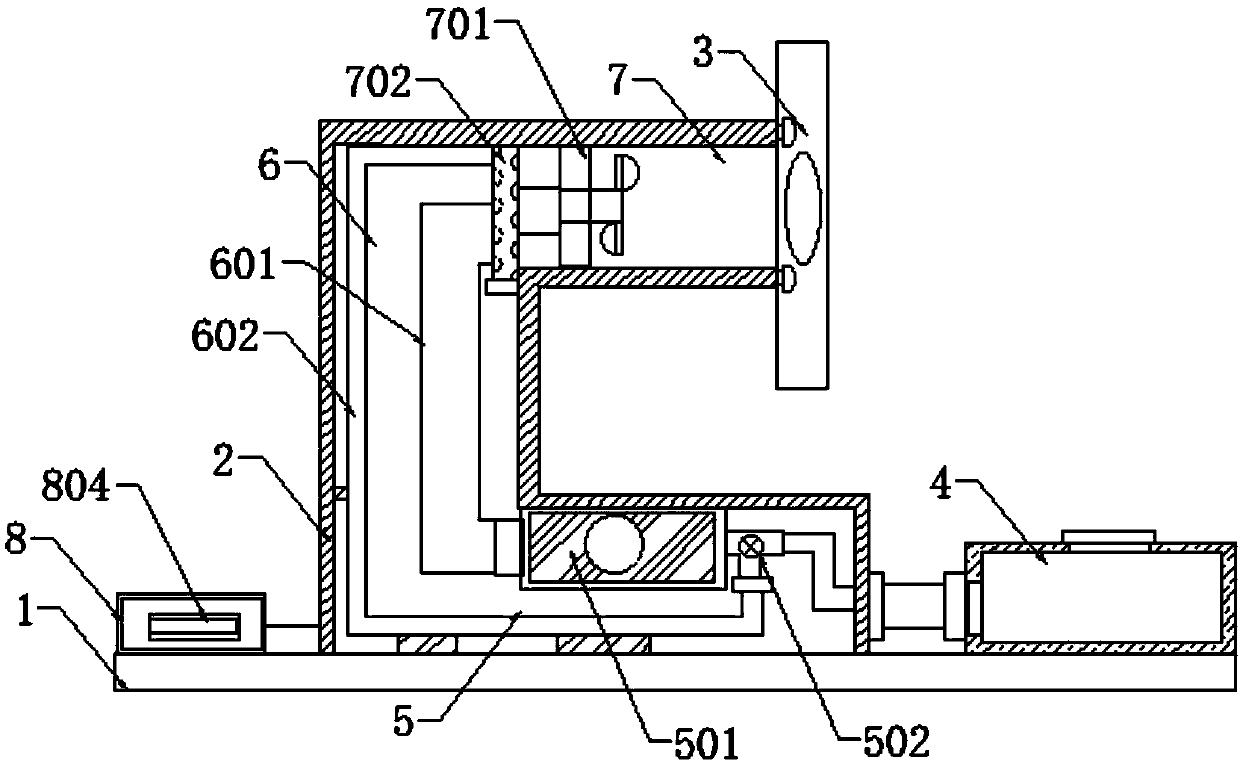

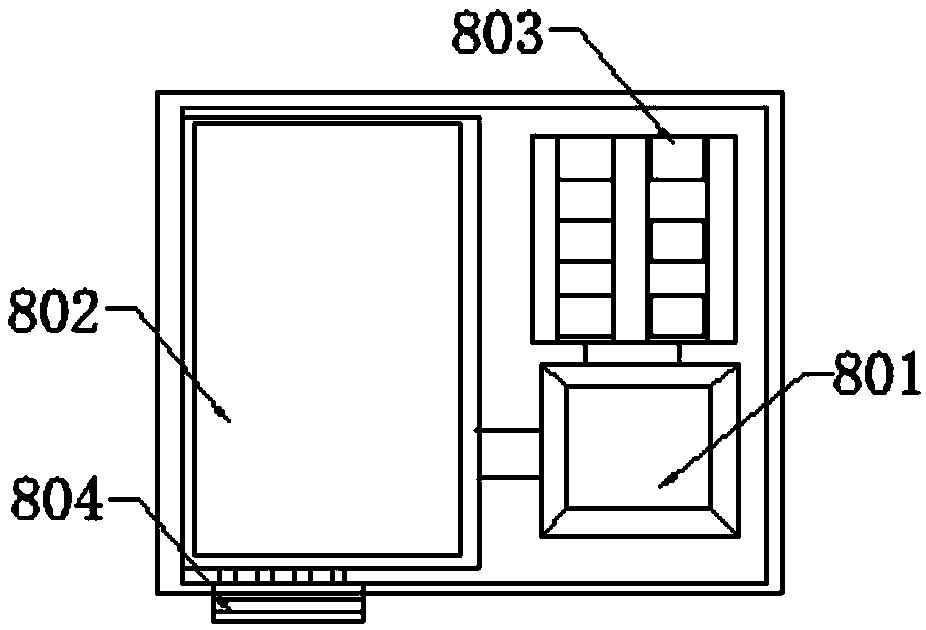

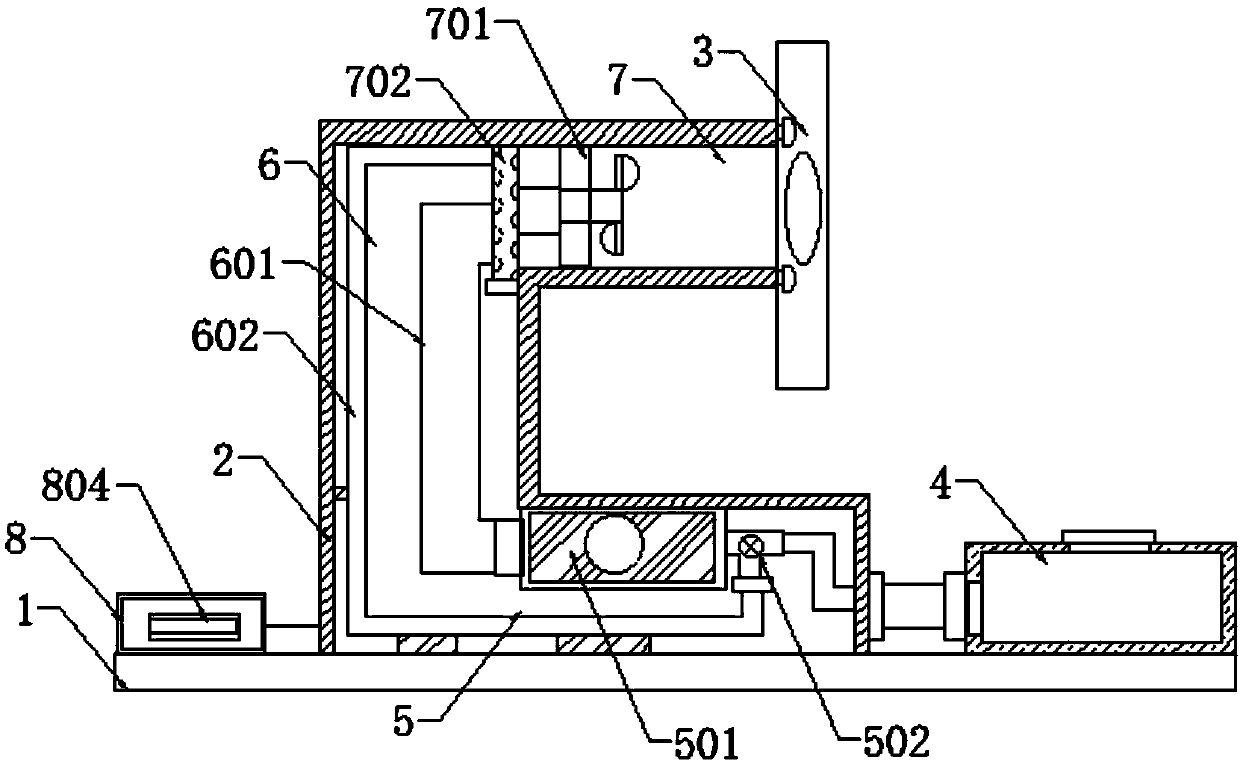

[0027] Such as figure 1 As shown, the present invention provides a multi-stage cold air heat dissipation device for electronic devices, including a heat dissipation base plate 1, the heat dissipation base plate 1 is a cuboid thin plate, and the four corners of the heat dissipation base plate 1 are dug with M5 standard threaded holes, and are fixed on the base plate to be fixed by screws. On the heat dissipation device base, a heat dissipation pipe 2 is welded on the upper surface of the heat dissipation base plate 1, and a heat dissipation fin 3 is installed at the outlet of the upper end of the heat dissipation pipe 2, and the heat dissipation fin 3 is close to the heat dissipation device; the heat dissipation pipe 2 The outlet at the lower end of the outlet is parallel to the heat dissipation bottom plate 1, and a refrigerant box 4 is connected through a pipeline. The refrigerant box 4 is made of heat-insulating material. Rubber sealing plug, refrigerant is stored in the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com