Self-propelled ear and stem harvesting corn combined harvester

A combine harvester and self-propelled technology, which is applied to harvesters, crop processors, agricultural machinery and implements, etc., can solve problems such as low efficiency, and achieve the effect of increasing productivity and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

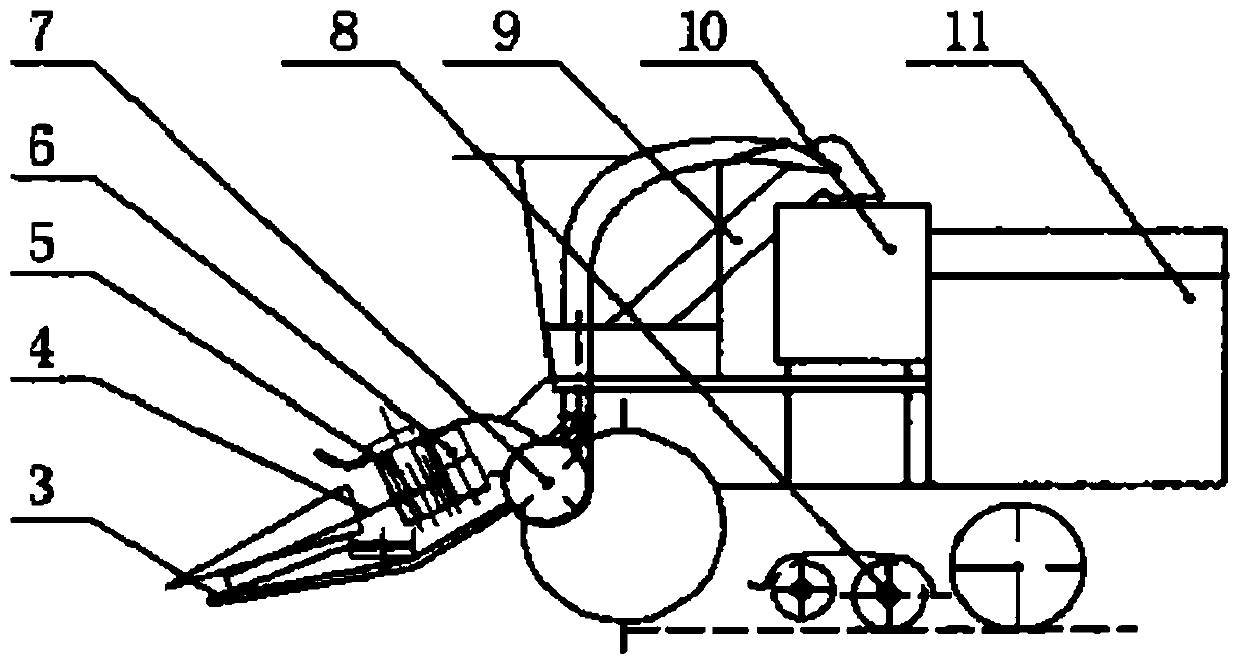

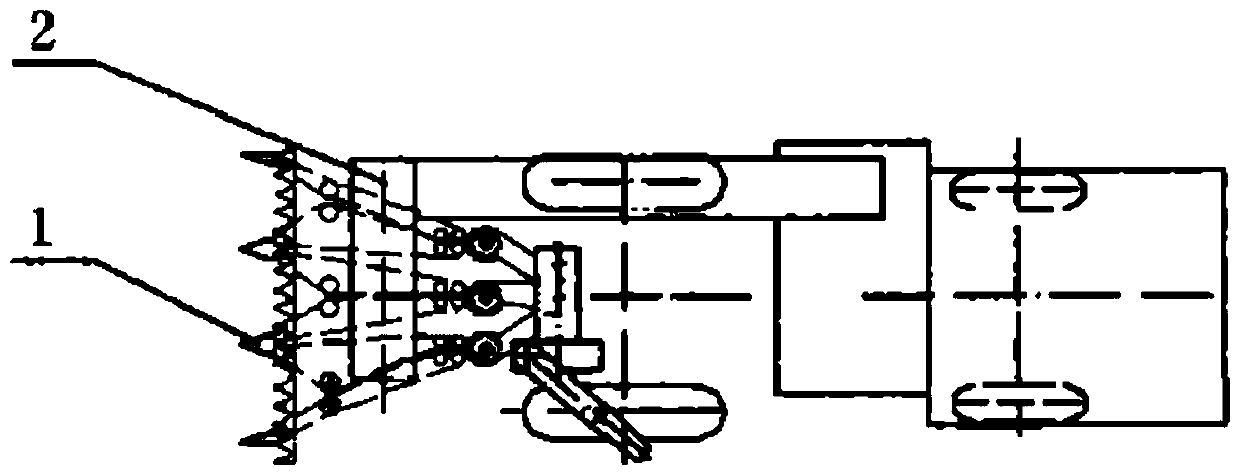

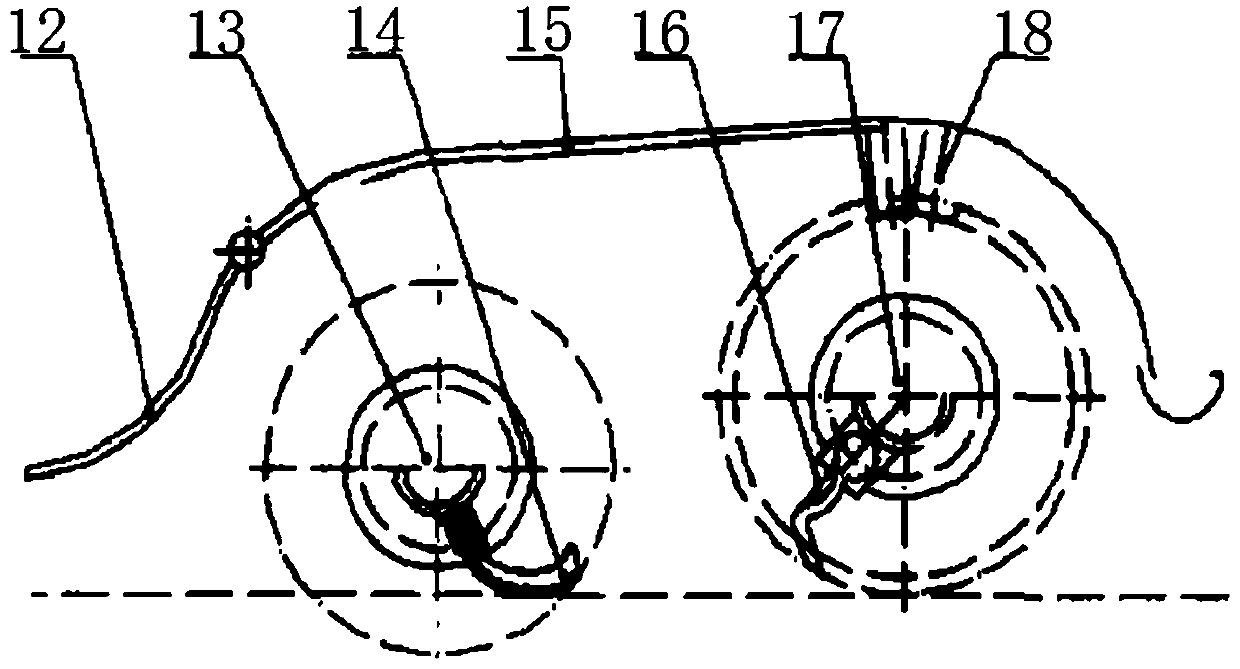

[0016] exist figure 1 , 2 Among them, it includes grain divider, horizontal conveyor, reciprocating cutter, clamping chain, picking roller, chopping roller, throwing device, stubble breaking device, elevator, ear device, stem collection box, etc. The feature is that: the corn plant is cut by the reciprocating cutter (3), and is transported by the clamping chain (4) to the vertical ear picking roller (5) for ear picking; the ears picked by the ear picking roller are transported by the horizontal conveyor (2) and the lifting The conveyer (9) is transported to the ear box (10); the corn stalks after picking the ears are sent to the hob for chopping through the stalk roller, and the screw conveyor is collected and fed to the thrower (7), and the thrower will The stalks are thrown into the stalk collection box (11) or the grass collector, and can also be thrown into the field and returned to the field; the corn stubble is broken by the stubble breaking device (8) and the ground is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap