Automatic food marinating production line and method

A production line and food technology, applied in dairy products, cheese substitutes, applications, etc., can solve problems such as secondary pollution, high management costs, and high labor intensity, achieve coherent processing, high intelligence, and change measurement errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

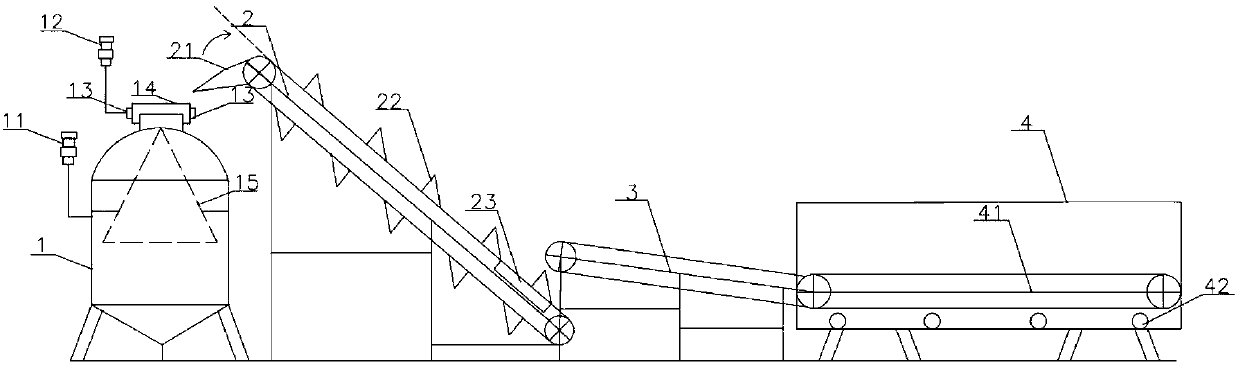

[0043] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0044] A preferred embodiment of the present invention provides an automatic food marinating production line, comprising:

[0045] The control device and the conveying and cleaning system connected with the control device, the conveying and cleaning system is used to transport the food to be marinated from the first position to the second position, and clean and drain the food to be marinated during the transport process;

[0046] A stewed tank for automatically stewing food to be stewed, a material guide device for introducing the food to be stewed into the stewed tank, and the stewed tank is connected to the control device;

[0047] The metering feeding system is installed between the conveying cleaning system and the material guiding device. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com