Tooth surface distortion compensation method during worm wheel grinding of axial modified helical gear

A technology of worm grinding wheel and compensation method, which is applied in the field of tooth surface distortion compensation when grinding helical gear worm grinding wheel with tooth direction modification, and can solve the problems of technical blockade, inability to know the principle and implementation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

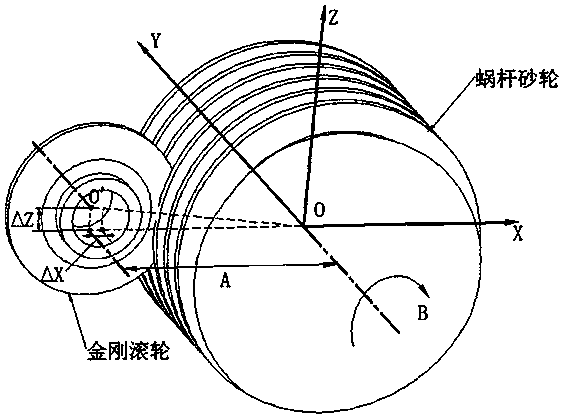

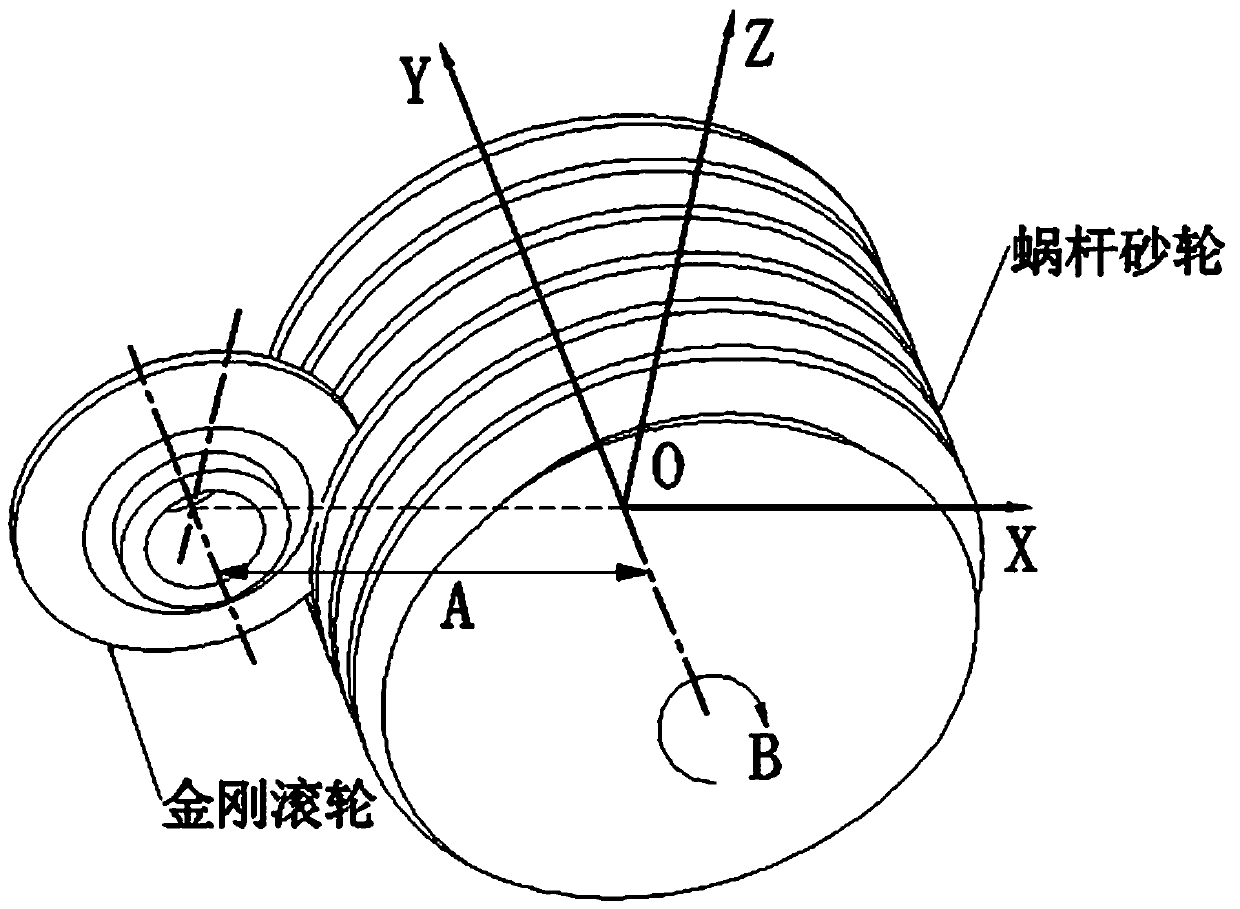

[0024] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

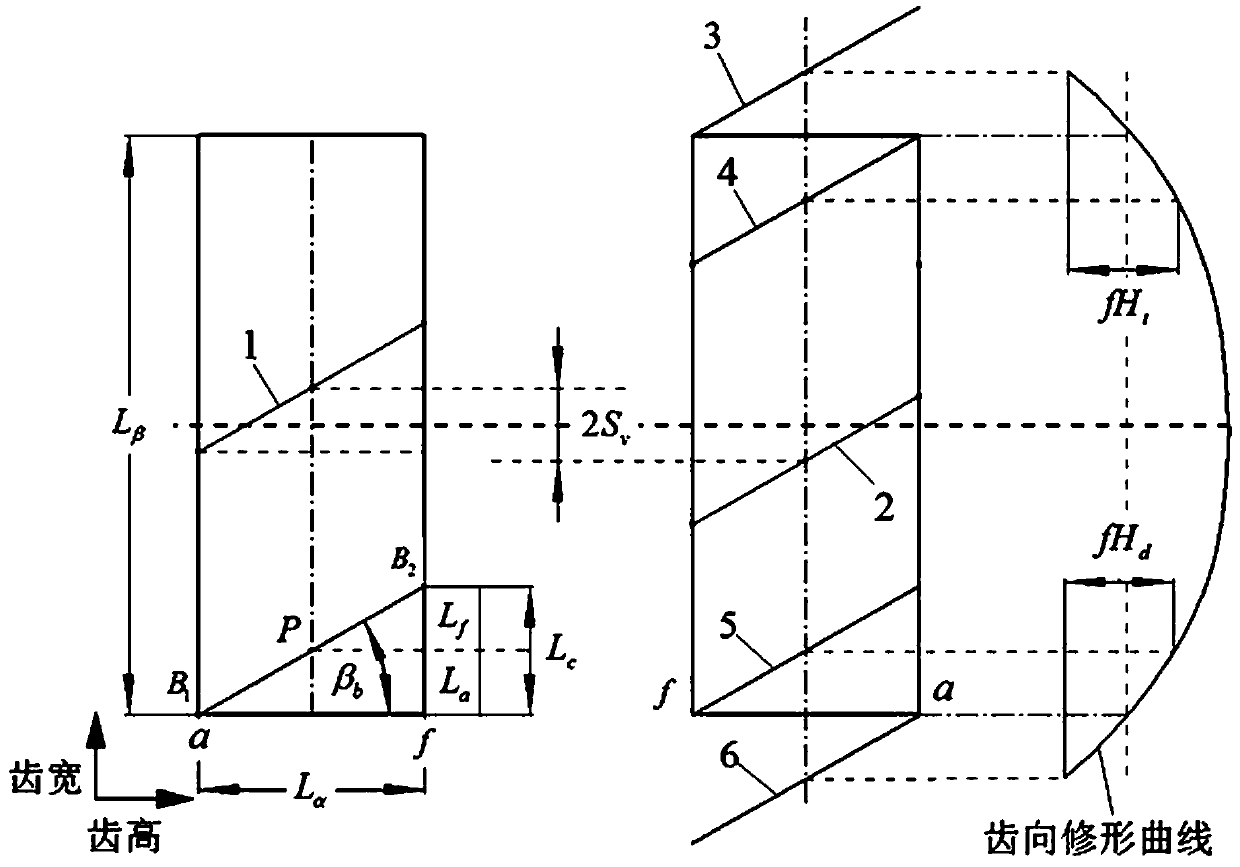

[0025] The distortion of the tooth surface refers to the phenomenon that the profile of the end section of the gear is gradually twisted in the tooth width direction, and the error value of the profile of the profile of the end section of the gear is equal to the error value at the top of the tooth minus the error value at the root of the tooth. Since there are tooth profile errors in the cross-sectional profile of each end of the tooth surface, and the tooth profile error changes continuously with the tooth profile modification curve, the absolute value of the tooth profile error at the upper and lower end surfaces of the general tooth surface is the largest, and the upper and lower end surfaces One of the tooth profile errors is a positive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com