Double-chain conveyor with attaching plate

A conveyor and double-chain technology, which is applied in the field of double-chain conveyors with attached plates, can solve the problems of plastic box position deviation and affect the stacking effect of robots, and achieve the effects of increased service life, compact structure and stable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

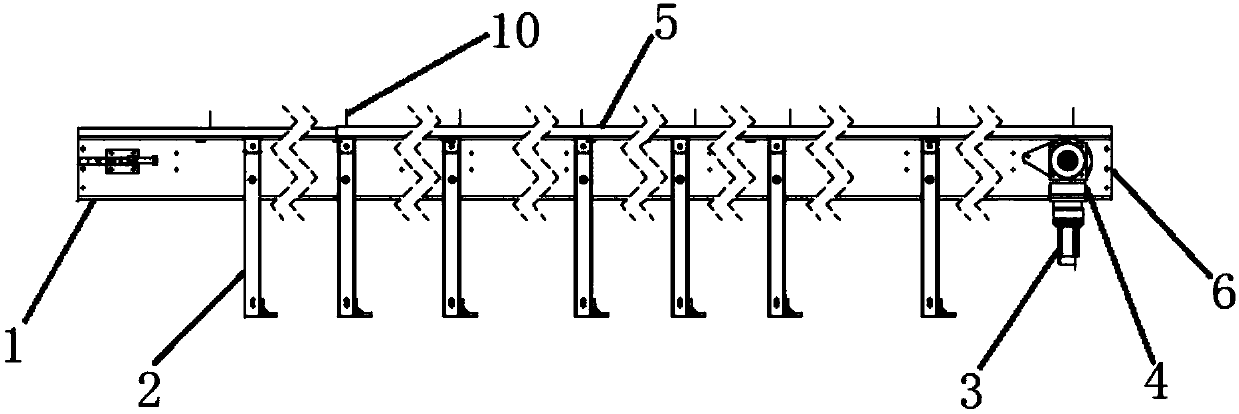

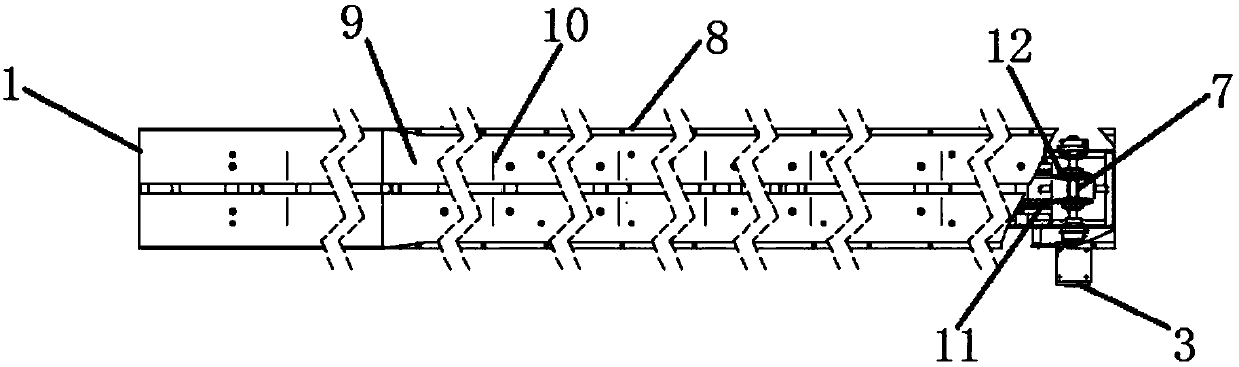

[0026] Such as Figure 1-2 Shown is a double-chain conveyor with attached plates, the conveyor includes a head 1, a fuselage 5 and a tail 6 connected in sequence, supporting legs 2 are provided on both sides of the fuselage 5, and a servo is provided in the tail 6 The motor 3 and a pair of driving sprockets 12 connected to the servo motor 3, a pair of driven sprockets are arranged in the machine head 1, and a stainless steel chain is wound between each driving sprocket 12 and the corresponding driven sprocket 11. The chain 11 is provided with an attached plate 9 along the horizontal direction, and a plurality of positioning baffles 10 perpendicular to the attached plate 9 are evenly arranged on the attached plate 9 . A speed reducer 4 is arranged in the tail 6, and the servo motor 3 is connected with the drive sprocket 12 through the speed reducer 4. The tail 6 is also provided with a drive shaft 7 that is in transmission connection with the reducer 4 , and the drive sprocket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com