Silicone rubber impact-resistant energy absorbing material and preparation method thereof

An energy-absorbing material and impact-resistant technology, applied in the fields of rubber impact-resistant energy-absorbing materials and their preparation, impact-resistant energy-absorbing materials and their preparation fields, can solve the problems of incompatibility between flexibility and impact resistance, and achieve easy-to-control, Strong energy dissipation ability and the effect of improving impact resistance and energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

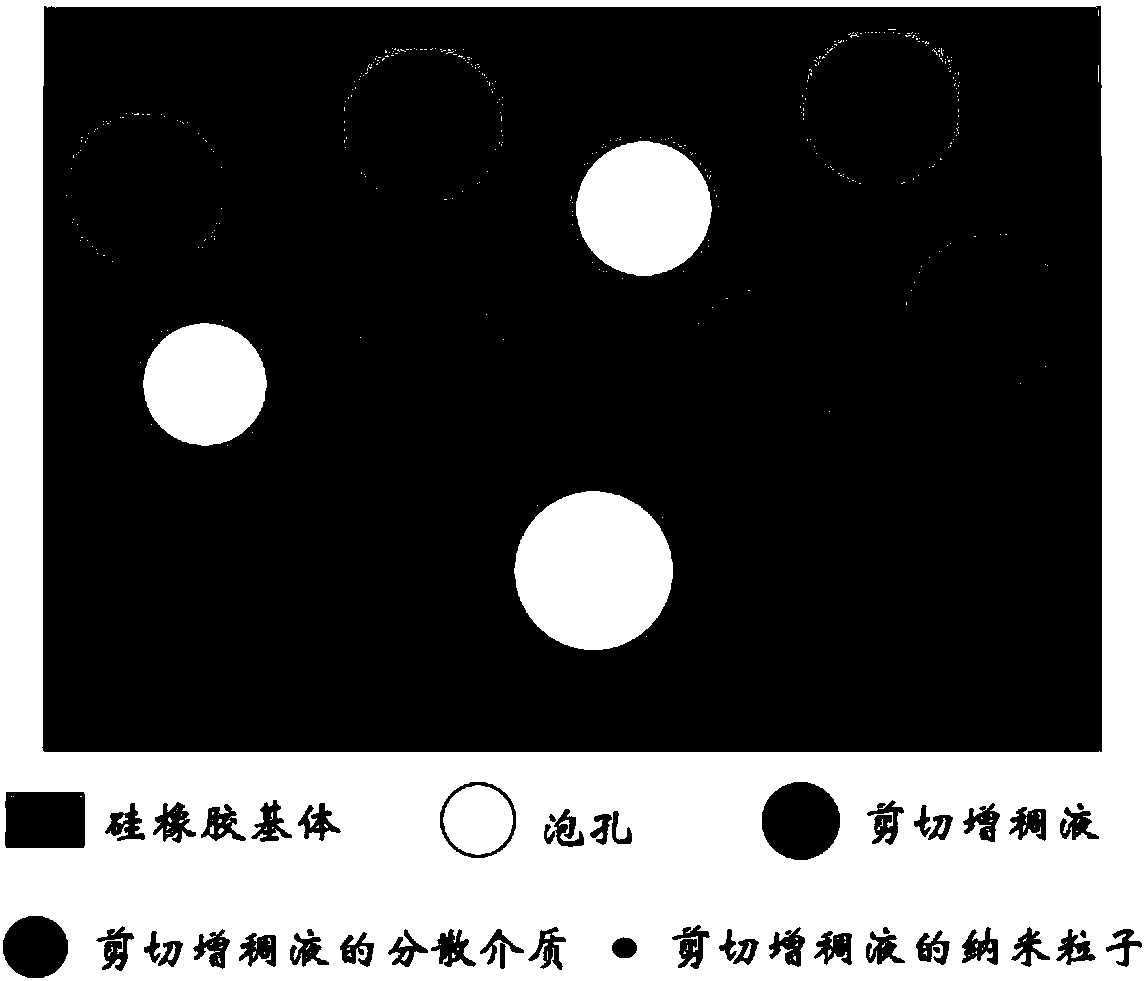

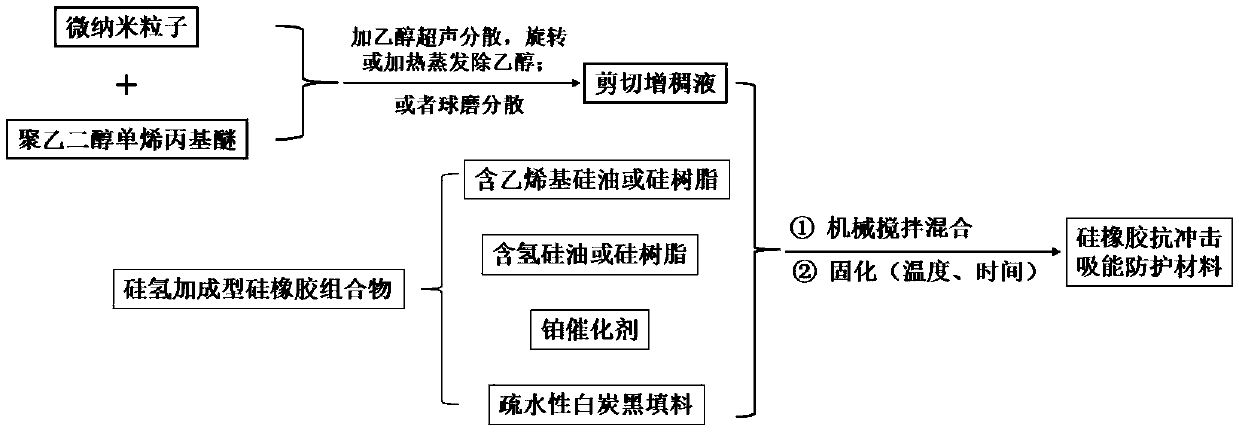

[0028] Add silica nanoparticles and polyethylene glycol monoallyl ether oligomer into the container at a weight ratio of 40:60, and then add the total amount of silica nanoparticles and polyethylene glycol monoallyl ether oligomer. 3 times the weight of ethanol, ultrasonically disperse until the silica nanoparticles are completely dispersed, and then remove the ethanol by rotating or heating evaporation to obtain a shear thickening solution.

[0029] Add vinyl-containing silicone oil or silicone resin, hydrogen-containing silicone oil or silicone resin, platinum catalyst, hydrophobic silica filler and the prepared shear thickening liquid into the mixing vessel in corresponding proportions, and mix under the action of mechanical stirring , and then cured at a temperature of 120° C. for 1 hour to obtain the silicone rubber impact-resistant energy-absorbing material of the present invention. The ratio of the total mass of vinyl-containing silicone oil or silicone resin, hydrogen-...

Embodiment 2

[0031] Add silica nanoparticles and polyethylene glycol monoallyl ether oligomer into the container at a weight ratio of 70:30, and then add the total amount of silica nanoparticles and polyethylene glycol monoallyl ether oligomer. 3 times the weight of ethanol, ultrasonically disperse until the silica nanoparticles are completely dispersed, and then remove the ethanol by rotating or heating evaporation to obtain a shear thickening solution.

[0032] Add vinyl-containing silicone oil or silicone resin, hydrogen-containing silicone oil or silicone resin, platinum catalyst, hydrophobic silica filler and the prepared shear thickening liquid into the mixing vessel in corresponding proportions, and mix under the action of mechanical stirring , and then cured at a temperature of 120° C. for 1 hour to obtain the silicone rubber impact-resistant energy-absorbing material of the present invention. The ratio of the total mass of vinyl-containing silicone oil or silicone resin, hydrogen-...

Embodiment 3

[0034] Add silica nanoparticles and polyethylene glycol monoallyl ether oligomer into the container at a weight ratio of 40:60, and then add the total amount of silica nanoparticles and polyethylene glycol monoallyl ether oligomer. 3 times the weight of ethanol, ultrasonically disperse until the silica nanoparticles are completely dispersed, and then remove the ethanol by rotating or heating evaporation to obtain a shear thickening solution.

[0035]Put vinyl-containing silicone oil or silicone resin, hydrogen-containing silicone oil or silicone resin, platinum catalyst, hydrophobic white carbon black filler, and the prepared shear thickening liquid into the mixing container in corresponding proportions, and mix under the action of mechanical stirring , and then cured at a temperature of 120° C. for 1 hour to obtain the silicone rubber impact-resistant and energy-absorbing material of the present invention. The ratio of the total mass of vinyl-containing silicone oil or silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com