Mobile Boehmeria nivea peeler

A hemp peeling machine, mobile technology, applied in mechanical processing, fiber mechanical separation, textiles and paper making, etc., can solve the problems of low efficiency of ramie peeling, and achieve the effect of strong skin and bone separation, compact structure, and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

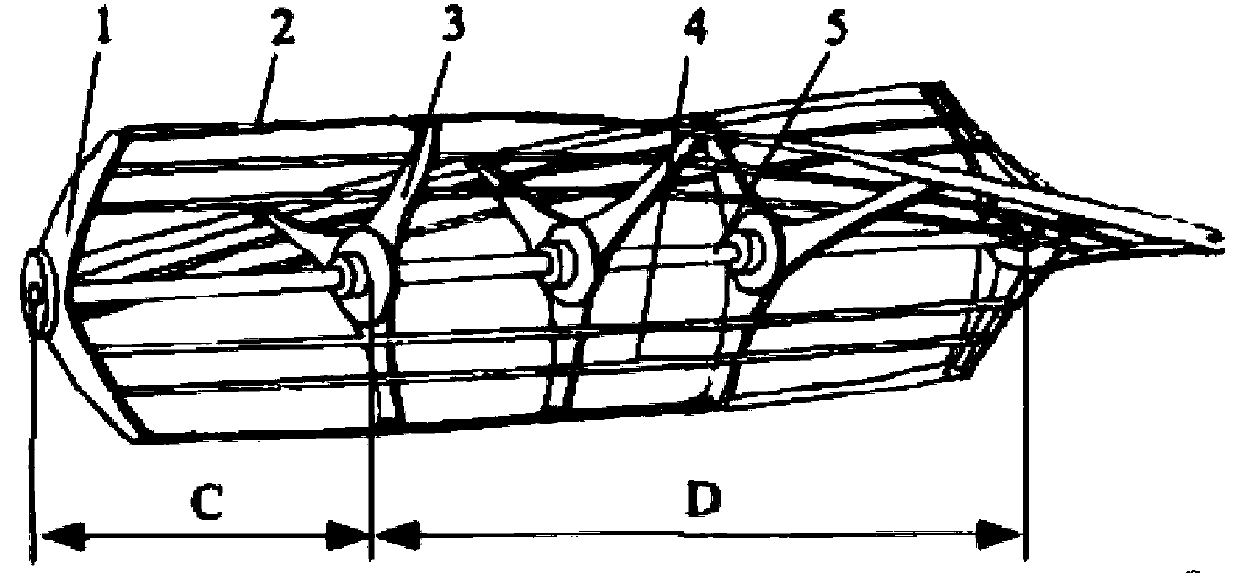

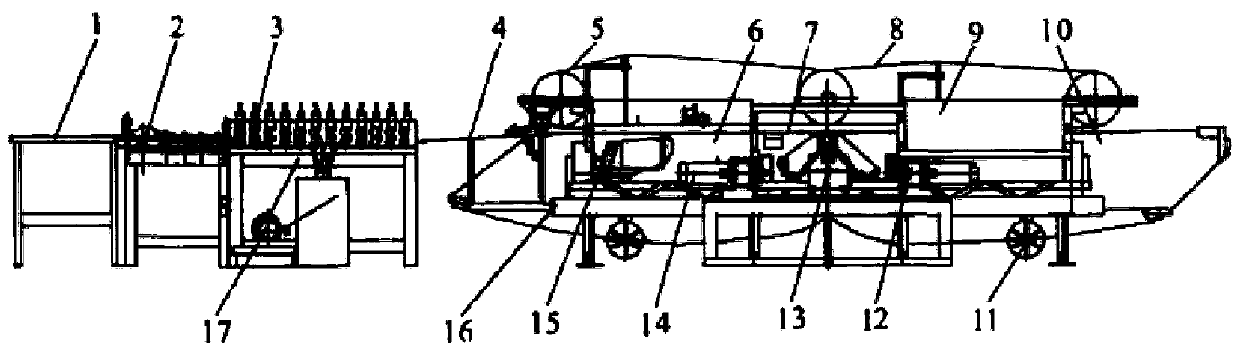

[0014] exist figure 1 Medium, including feeding platform, tooth plate feeding machine, stem crushing roller, hemp feeding table, front clamping conveyor belt, one-section hemp stripper, reversing mechanism, rear clamping belt, two-section hemp stripper, hemp receiving Platform, walking wheel, two-section flax stripper motor, conveyor belt motor, one-section flax stripper motor, spiral stripper roller, main frame, stem crushing machine motor, among them, when the equipment is working, the dry flax stems on platform 1 are fed It is brought into the tooth plate thin-layer machine 2 in parallel by the tooth disc, laid evenly, and then sent to the stem crushing machine; compressed by 12 pairs of parallel stem crushing rollers 3, the hemp bone is broken and separated from the fiber, and sent to the hemp feeding table 4 ;The 1 / 3 part of the hemp that is clamped by the front clamping conveyor belt 5 enters a section of hemp stripper 6, and during the conveying process, a pair of relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com