Curtain wall keel connecting structure for final installation of horizontal keels

A technology for connecting structures and horizontal keels, applied to walls, building components, building structures, etc., can solve the problems of poor connection strength between horizontal keels and vertical keels, reduce the service life of curtain walls, and affect the installation of curtain wall panels, etc., to achieve simplicity and refinement Good performance and service life, anti-rust performance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

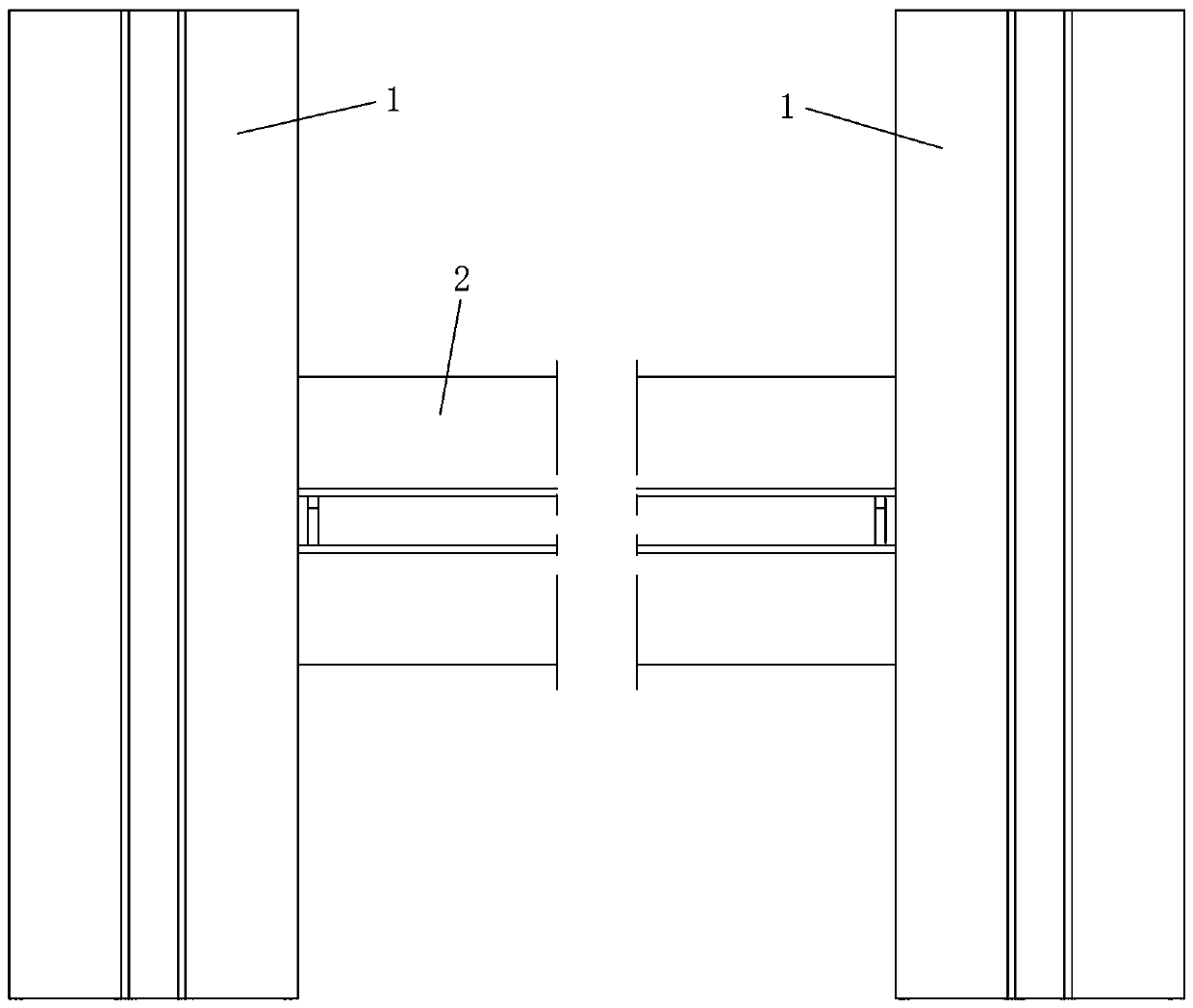

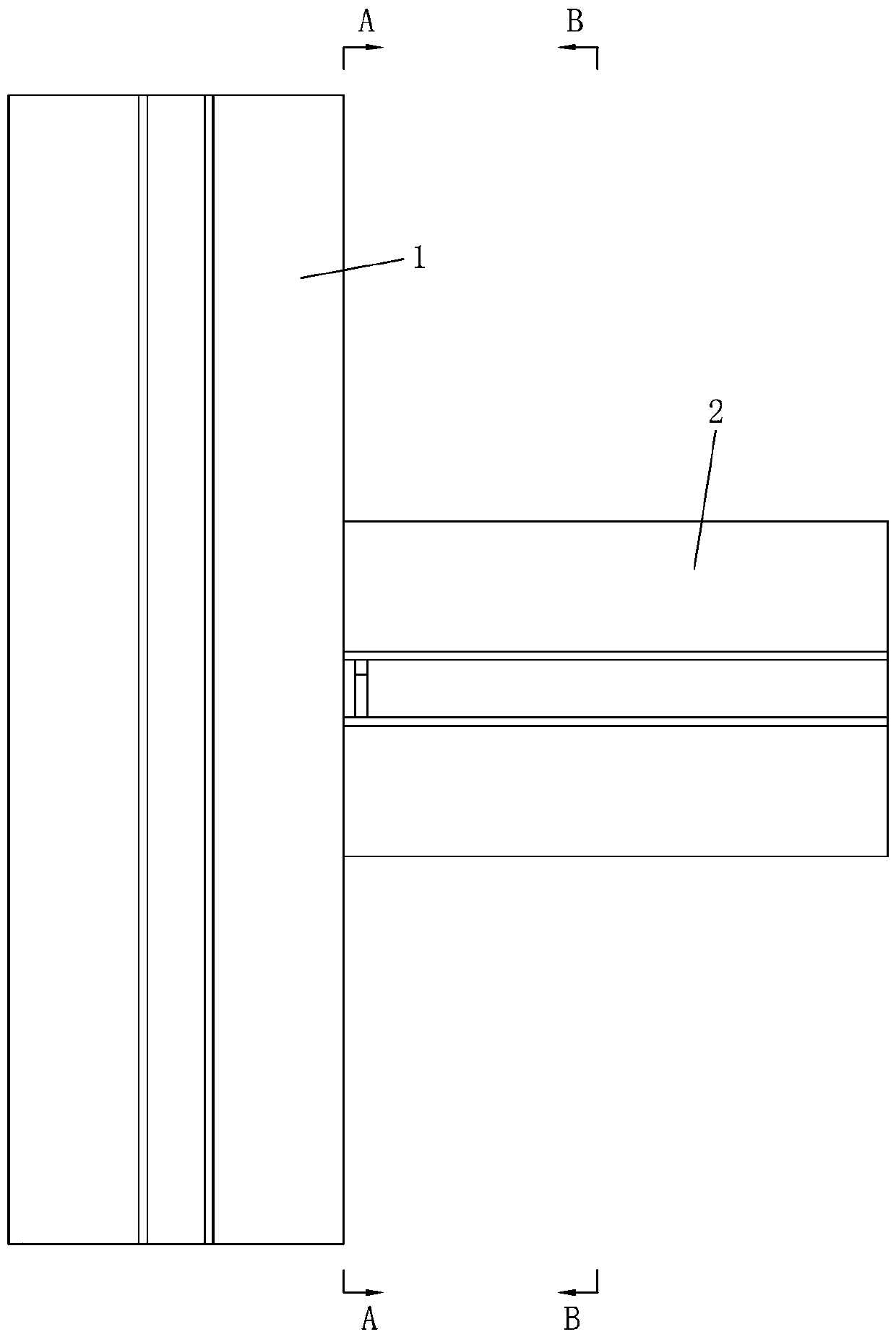

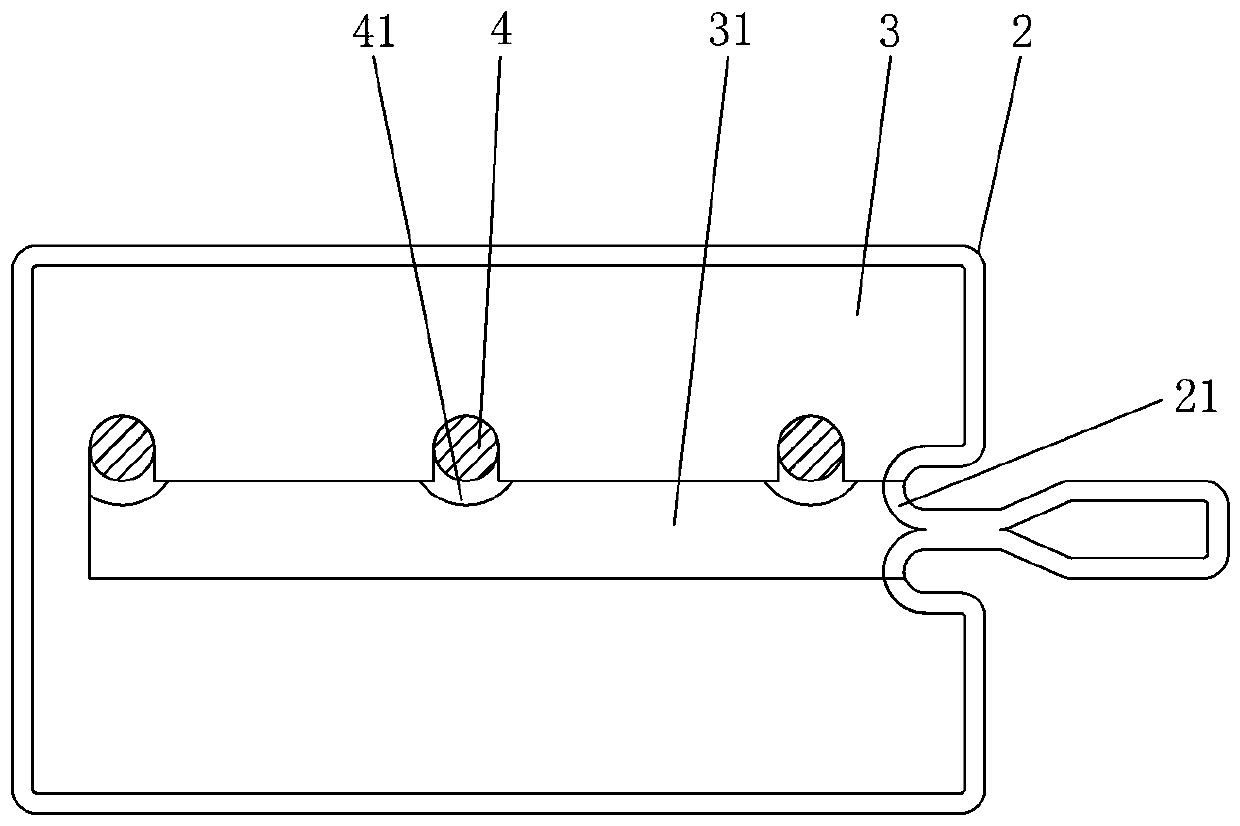

[0039] Such as Figure 1 to Figure 5 As shown, the curtain wall keel connection structure for post-installation of the horizontal keel in this embodiment includes two vertical keels 1 and a horizontal keel 2 installed between the two vertical keels 1, and the horizontal keel 2 is a circumferentially closed tubular profile , each vertical keel 1 is connected with a shear connection assembly located in the inner cavity of the horizontal keel 2 and supports the horizontal keel 2, the shear connection assembly includes an inner connecting piece 3 fixedly installed in the inner cavity of the horizontal keel 2, and the inner connecting piece 3 An open slot 31 with an open end is provided, and more than one supporting part 4 that can be inserted into the open slot 31 from the opening of the open slot 31 is installed on the vertical keel 1, and each supporting part 4 is located in the open slot 31 and holds the Connector 3, the opening groove 31 is provided with a card sleeve on the s...

Embodiment 2

[0047] The curtain wall keel connection structure used for the post-installation of the transverse keel in this embodiment is basically the same as in Embodiment 1, the main difference is that, as Image 6 with Figure 7 As shown, in this embodiment, only one supporting part 4 is installed on the vertical keel 1, and the top end of the supporting part 4 is provided with a supporting surface that contacts and cooperates with the internal connecting part 3 and supports the internal connecting part 3. The contact surface between the holding surface and the inner connector 3 is a horizontal plane, so as to improve the stability of supporting the transverse keel 2 .

Embodiment 3

[0049] The curtain wall keel connection structure used for the post-installation of the transverse keel in this embodiment is basically the same as in Embodiment 1, the main difference is that, as Figure 8 with Figure 9 As shown, in this embodiment, the anti-retraction bayonet 311 is a circular opening communicating with the opening groove 31, and the supporting member 4 is a bar that is inserted into the circular opening from the opening groove 31 and prevents the inner connecting member 3 from moving up and down and back and forth. Shaped parts, the supporting part 4 simultaneously limits the freedom of the transverse keel 2 in the up and down and front and rear directions, which can improve the stability of the transverse keel 2 after installation.

[0050] In this embodiment, a connection assembly connected to the vertical keel 1 is connected to the outside of the horizontal keel 2 to strengthen the connection and prevent the relative rotation of the supporting part 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com