Tight oil energy supplying method of alternating displacement and imbibition oil displacement between horizontal well sections

A horizontal well section and energy replenishment technology, which is applied in earthwork drilling, wellbore/well components, and production fluids, etc., can solve the problems of difficult energy replenishment in development, slow lateral displacement of water flooding, etc., and achieve the goal of overcoming development energy Complement the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

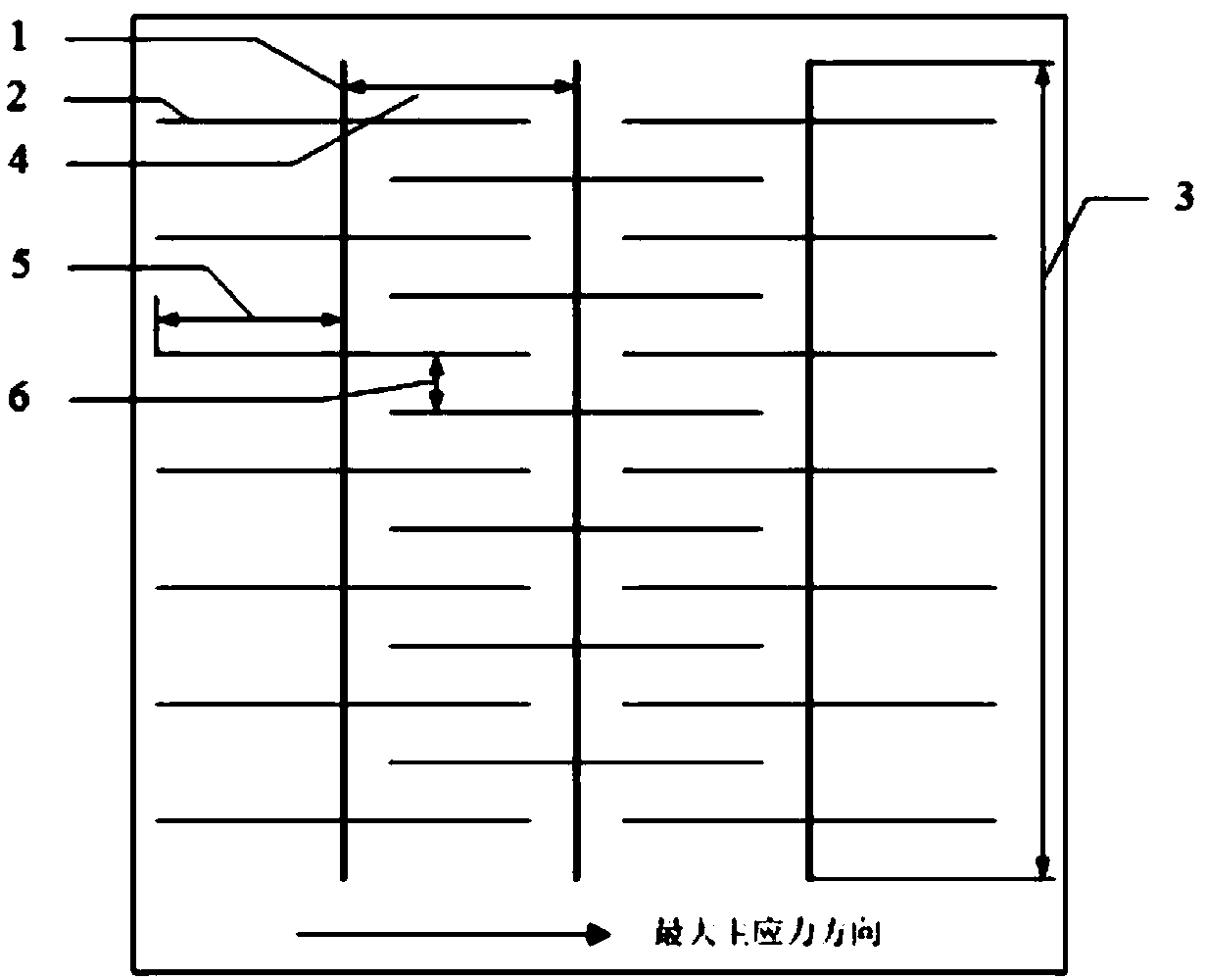

[0065] In order to overcome the problem of difficult energy replenishment in the development of horizontal wells in tight oil reservoirs, this embodiment provides a tight oil energy replenishment method for interlaced displacement and imbibition displacement between horizontal well intervals, see figure 1 and figure 2 , including the following steps:

[0066] Step 1) selecting and classifying the reservoirs, dividing the reservoirs into grades I, II and III, and deploying and exploiting the horizontal well 1 sequentially according to the reservoirs of grades I, II and III;

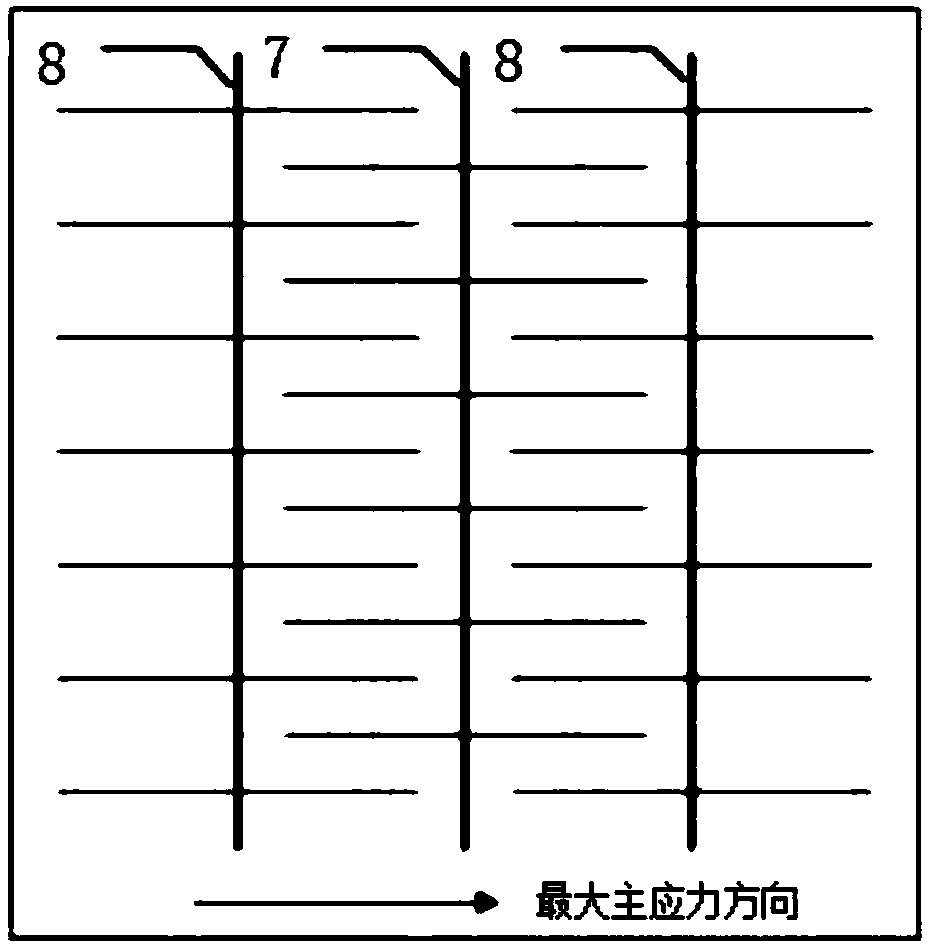

[0067] Step 2) Deployment of horizontal wells 1: a plurality of horizontal wells 1 are sequentially arranged on the I, II, and III level reservoirs, and then a plurality of artificial fractures 2 are fractured in the vertical direction of each horizontal well 1, and the horizontal wells 1 two The lengths of the artificial fractures 2 on the side are equal. The setting of the horizontal well 1 includes th...

Embodiment 2

[0077] On the basis of Example 1, this example provides a tight oil energy replenishment method for interlaced displacement and imbibition flooding between horizontal well sections. Further, the selection of reservoirs in step 1) includes the following two point:

[0078] ① On the plane, the classification coefficient is established by four parameters of reservoir porosity, movable fluid saturation, mainstream throat radius and starting pressure gradient, and the reservoir is divided into grades I, II and III according to the classification coefficient and permeability;

[0079] The reservoir porosity of the first-level reservoir is 6.7-8.0%, the movable fluid saturation is 53-62%, the mainstream throat radius is 1.3-2.5 μm, the starting pressure gradient is 0.05-0.2 MPa / m, and the classification coefficient is 1.5-2.5 μm. 3.5, the permeability is 0.5~1.0mD;

[0080] The reservoir porosity of the second-level reservoir is 5.6-8.0%, the movable fluid saturation is 42-55%, the ...

Embodiment 3

[0084]On the basis of Example 1, this example provides a tight oil energy replenishment method for interlaced displacement and imbibition flooding between horizontal well sections. Further, the direction of the horizontal well in step 2) is perpendicular to The direction of the maximum principal stress, the length 3 of the horizontal section does not exceed 1500m, and the well spacing 4 is the half length of the artificial fracture 5.

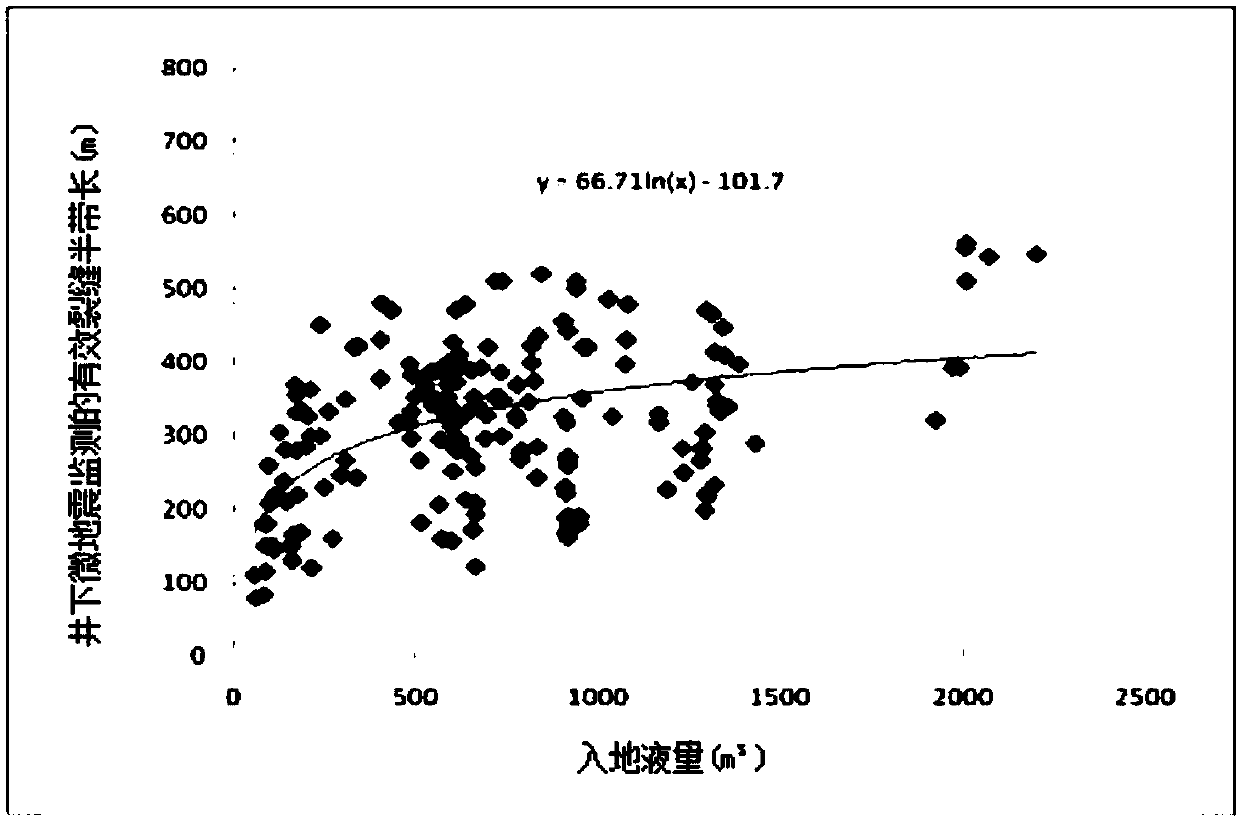

[0085] According to imaging logging and downhole microseismic test results, the maximum principal stress direction is generally NE75°, and the horizontal well direction is perpendicular to the maximum principal stress direction to ensure the best fracturing effect for horizontal wells in the fracturing process and improve Single well production. The design of the length of the horizontal section on the well pattern deployment is not only affected by the distribution characteristics of the continuity of the oil layer, but also the maturity of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com